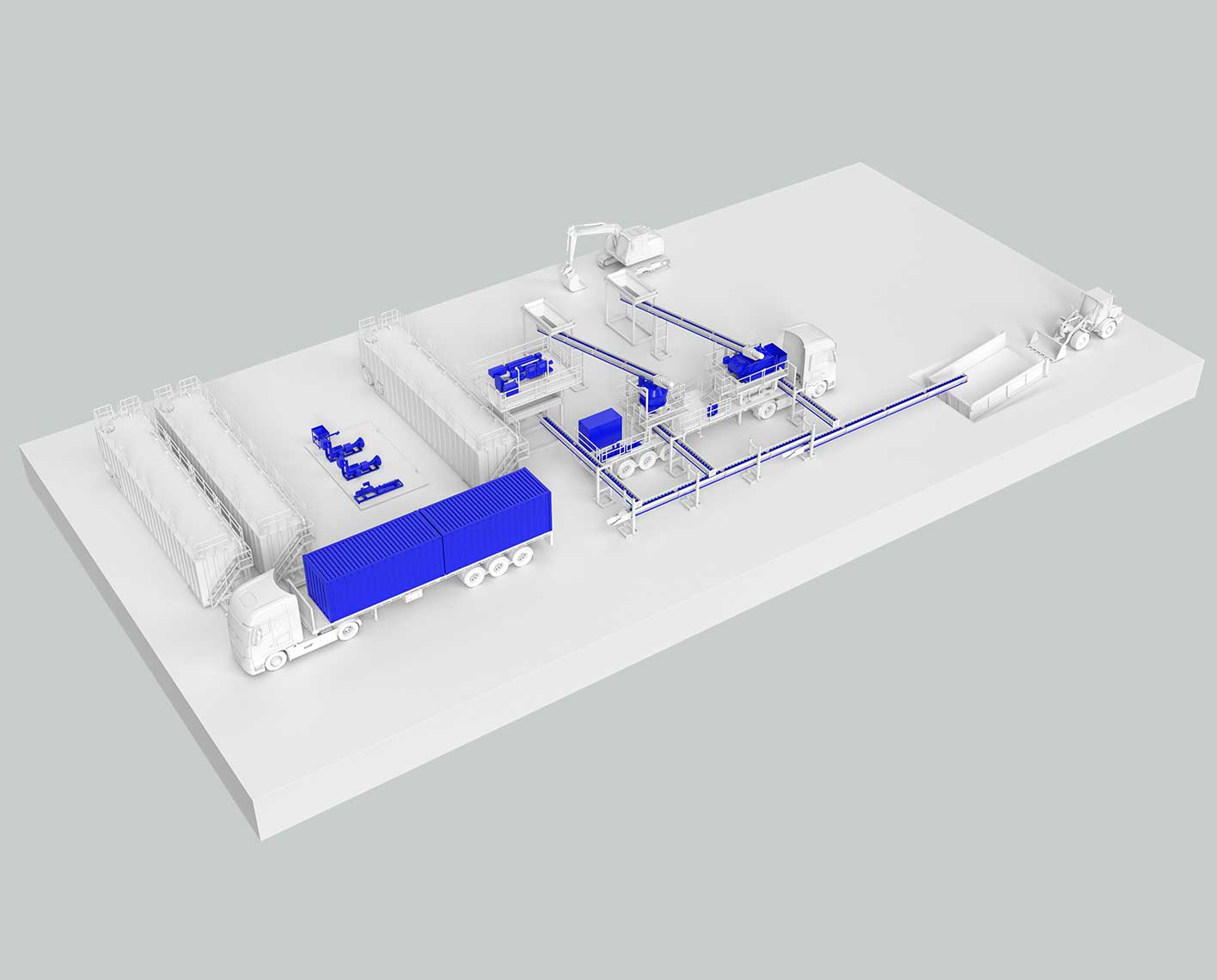

Cuttings Management and Recycling System

Reduces waste, conserves water, and recycles drilling mud

Minimizes environmental impact while recovering resources for reuse

Traditional waste management and solids control methods are resource-intensive, consuming significant amounts of fresh water and producing substantial solid and liquid waste. This leads to higher emissions from transportation and disposal processes, we well as increased costs. The cuttings management and recycling system (CMRS) from SLB solves these challenges by combining technologies that decrease waste volume and improve water efficiency.

At the core of the CMRS is an innovative water management strategy that eliminates unnecessary flushes, optimizes drilling fluid displacement, and maximizes wastewater recycling. These measures not only conserve water but also minimize the environmental footprint of drilling operations. By reclaiming valuable resources and integrating water conservation into every step of the process, the CMRS reduces transportation and disposal emissions while driving down costs. The CMRS recovers and recycles drilling mud while reducing solid waste by using efficient separation and treatment methods. This process helps minimize environmental impact and enables valuable resources to be reclaimed and reused.

Reduces waste and water usage

Integrates technologies that reduce waste volume and conserves water

Lowers disposal costs

Reducing logistics requirements lowers waste disposal costs

Recovers and recycles drilling mud

Separation and treatment processes maximize the recovery and recycling of drilling mud

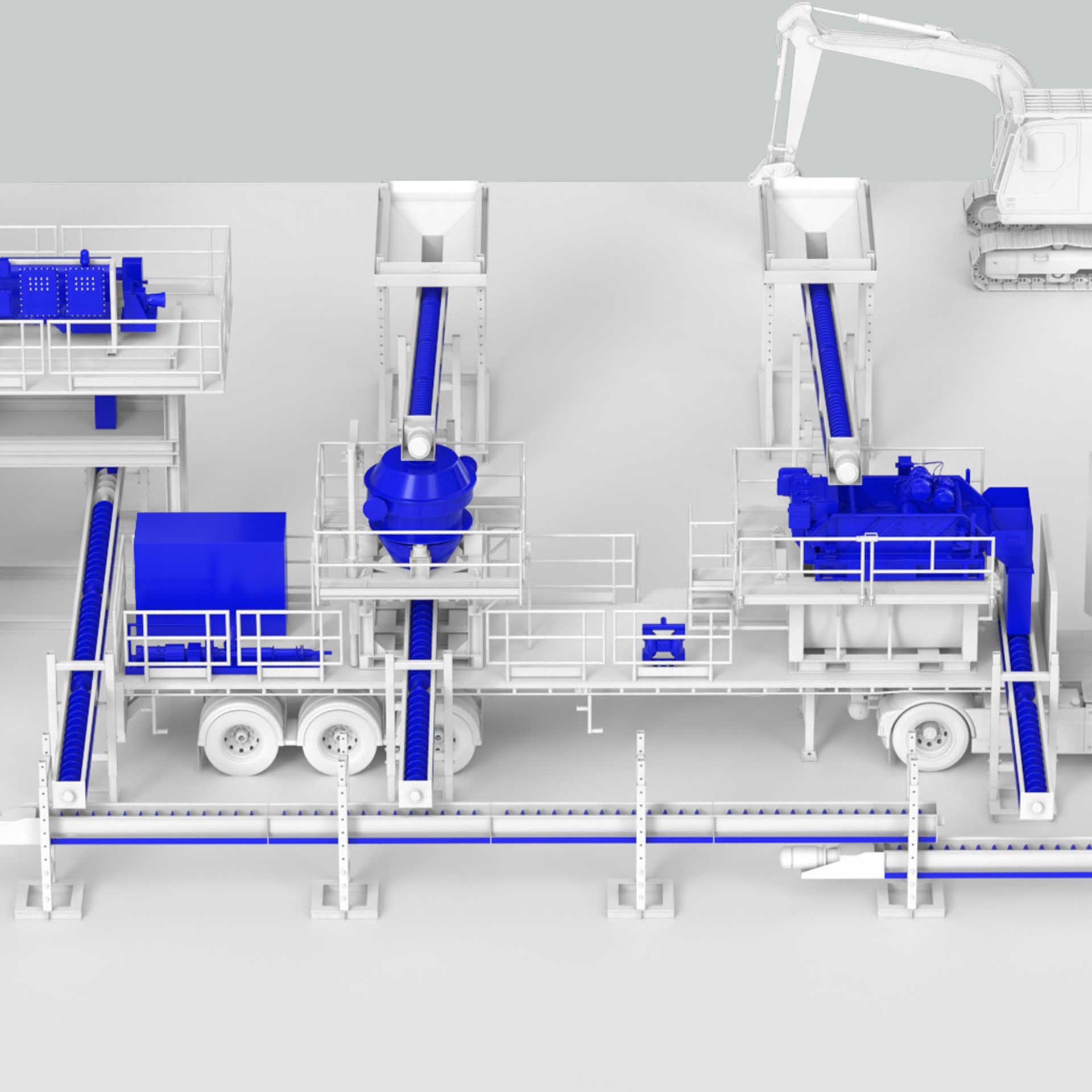

Combining Key SLB Technologies

The CMRS incorporates the full SLB environmental solutions technology portfolio. Key system components include advanced separation with VERTI-G™ cuttings dryers, high-speed centrifuges, a drying shaker package, screw conveyor integration, advanced filtration and water treatment technologies, and automatic tank cleaning.