Optiq distributed acoustic sensing interrogator

For optimizing use of optical fibers in wells and pipelines for oil and gas, geothermal, and CCS operations.

51 mm [2 in] or more

1–300 bar [14.5–4,350 psi]

Real-time response, accurate to within 25 m [82 ft]

Suitable for pipelines transporting crude oil, refined products, or water

Developed by Eni and Enivibes for continuous monitoring of oil and gas pipelines in real time, retrofittable e-vpms® technology is ideal in situations where fiber-optic infrastructure is limited. Multiple sensors are deployed at discrete distances along the pipeline to monitor both the fluid behavior within the pipe and acoustic waves travelling along the pipe wall. Sensors can be placed up to 50 km [31 mi] apart and have low bandwidth and power requirements. You can use existing facilities or we can provide fit-for-purpose solutions for power and communication.

Quick navigation:

The e-vpms® technology identifies leaks and spills by using a combination of pressure, microvibration, and sound detection. Distance between the sensors can be selected to balance performance levels with factors such as available infrastructure and security. In addition to detecting holes with diameters as small as 0.1 in, the system can detect impacts on the pipeline from attempted theft or mechanical diggers excavating the ground.

The e-vpms® has been deployed on block valve stations for buried pipelines as well as on exposed pipelines transporting crude oil, refined products, and injection water. For subsea pipelines, the system is installed topside. Alarms are transmitted to operations teams in real time to notify them of incidents and events, together with precise locations and times of occurrence.

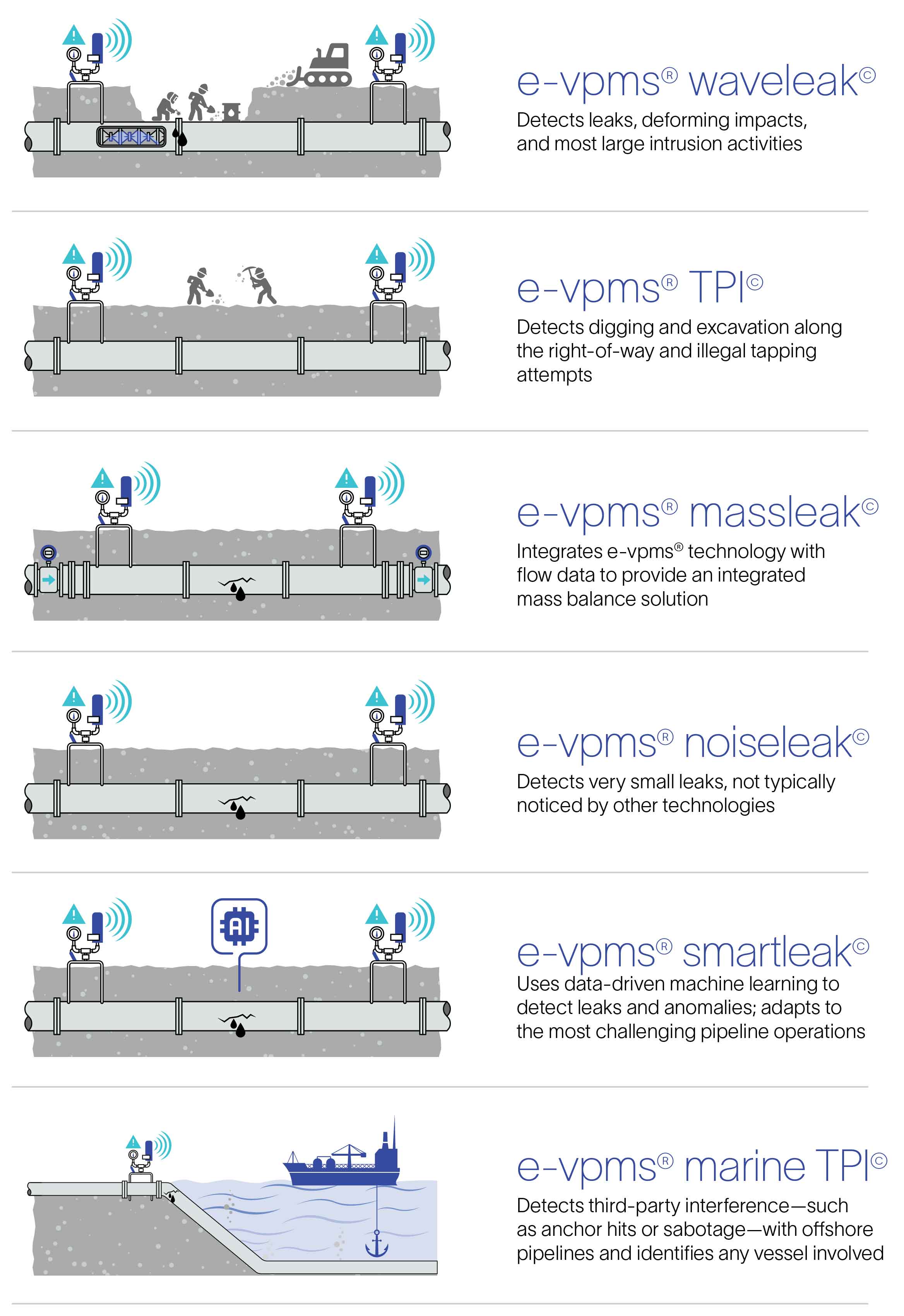

Six e-vpms® solutions are currently available.

A pig moving inside a pipeline is a vibroacoustic source. The resulting waves are detected by the e-vpms® sensors, which then compute the pig's location and velocity. Availability and accuracy of this information is vital for operations teams to locate the pig with low risk. Removing personnel from high-risk operations reduces the carbon footprint of your operation and helps optimize resources.

If a pig is stuck in the pipeline, the e-vpms® can be deployed as a temporary measure to locate the pig through advanced analysis of acoustic reflections. This type of analysis can also locate impact points along the pipeline.

Earthquakes and subsidence can be detected and potential damage assessed in real time. Alarm sensitivity can be adjusted depending on the region's susceptibility to these phenomena. The sensors have detected earthquakes with the epicenter located almost 1,000 km away.

The e-vpms® provides versatile support for both hydrostatic and pneumatic tests via sensors that are temporarily installed for the purpose or already permanently deployed on the pipeline for leak detection.

Supported by a track record of detecting multiple leaks and attempted thefts, the e-vpms® helps protect people and the environment and enables pipeline operators to avoid costly remediation, regulatory fines, and product loss.

With >2,000 km [>1,240 mi] of installations in Africa, Europe, and South America, the technology enables monitoring in both pumping and static states with negligible nuisance alarm rates and false alarm rates (NARFAR). The sensor package is easily deployed and provides accurate event monitoring to within 25 m [82 ft]. The shallow-water sensor variant can be submerged up to 10 m [33 ft] deep (e.g., in swampy areas).

Vibroacoustics uses a combination of sound, pressure, and microvibrations to detect a variety of phenomena.

Eni is enhancing the market value of its proprietary technology e-vpms® Eni vibroacoustic pipeline monitoring system, dedicated to the monitoring of liquid transportation pipelines and aimed at optimally protecting their integrity. For that purpose, it created Enivibes (76% Eniverse, 16% Aresys, and 8% Solgeo), the first venture established as part of the activities of Eniverse, Eni's corporate venture builder. (Source: Eni press release)

Visit Pipeline Integrity Services to view our full portfolio.

e-vpms is a mark of Eni. The e-vpms trademark is registered by Eni in the European Union, Canada, Russia, and the US.

waveleak, TPI, massleak, noiseleak, smartleak, and marine TPI are software products; Enivibes is the copyright owner.

The e-vpms® technology and patents are owned by Enivibes.