Enhanced safety and seal reliability.

How It Works: Double Block-and-Bleed and Double Isolation-and-Bleed

Published: 01/09/2015

How It Works: Double Block-and-Bleed and Double Isolation-and-Bleed

Published: 01/09/2015

The definitions of double block and bleed (DBB) and double isolation and bleed (DIB) differ between sources in the oil and gas industry. Differences in definitions and terms are important when it comes to which valve capability to use in what type of system. Because DBB and DIB have become such generic terms in the industry, it is important to take into consideration the application, media, and various environmental challenges when choosing the appropriate solution and valve type.

DBB definitions

There are two entities in the United States that define DBB—API and OSHA. According to API, a DBB valve is a "single valve with two seating surfaces that, in the closed position, provides a seal against pressure from both ends of the valve, with a means of venting/bleeding the cavity between the seating surfaces." API also notes in this definition that this valve does not provide positive double isolation when only one side is under pressure.

In contrast, OSHA describes DBB as "the closure of a line, duct, or pipe by closing and locking or tagging two inline valves and by opening and locking or tagging a drain or vent valve in the line between the two closed valves."

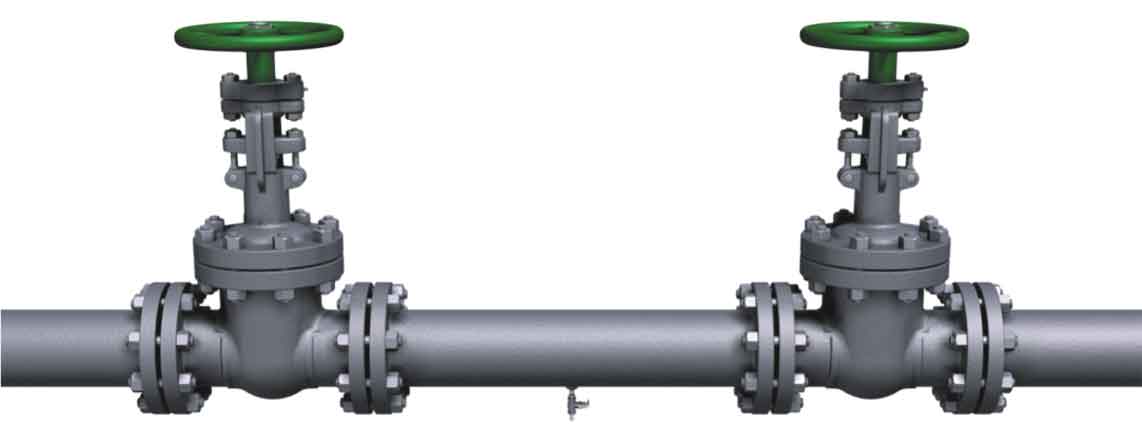

API's DBB definition does not achieve the same level of isolation as OSHA's. API allows DBB valves to be one single valve with two unidirectional seats, while the OSHA standard can only be achieved with two separate valves with a method to bleed pressure in between. There are some valves that utilize a twin-valve design. By combining two valves into one body, a twin-valve design reduces weight and potential leaks paths while meeting the OSHA requirements for double block and bleed.

Valve associations usually choose to follow either API's or OSHA's definition, but some have created their own handbook with their own definitions for industry terms. For example, the British Valve and Actuator Association (BVAA) defines DBB as "a manifold that combines one or more isolation valves, usually ball valves, and one or more bleed/vent, usually a needle-style global valve, into one assembly for interface with other components (e.g., pressure measurement transmitters, pressure gauges, and switches)."

DIB definition

API defines DIB as a “single valve with two seating surfaces, each of which, in the closed position, provides a seal against pressure from a single source, with a means of venting/bleeding the cavity between the seating surfaces.” This feature can be provided in one direction or in both directions.

The difference between API’s DBB and DIB definitions is that a double block and bleed valve seals against pressures from both sides of the valve while a double isolation-and-bleed valve provides an additional seal against pressure from only one side. It is important to use a DIB valve instead of a DBB valve in applications that require an additional pressure barrier that seals separately of the main pressure barrier. This is important to fulfill certain operational safety requirements or according to the nature of the service, such as low tolerance for leakage or the cleanliness of the fluid.

Differences of DIB and DBB

With a DBB valve, there are usually two unidirectional self-relieving seats. These seats do not rely on an outside mechanism to relieve pressure. In contrast, a DIB valve utilizes one or two bidirectional seats. The valve provides double isolation from pressure at both ends of the valve but cannot relieve body cavity pressure past the seats. DIB valves require an external relief system to relieve pressure buildup.

Both valves can provide isolation in both the upstream and downstream directions, even in high-pressure or high-temperature situations. Isolation is important in cases where leakage through a valve could have major consequences. Once the fluid is isolated, the bleed mechanism can drain the area between the two valves or two seating surfaces. This is important for maintenance and integrity check situations where leakage can be monitored.

Benefits

Both DBB and DIB valves save space, reduce the need for costly multivalve systems, and provide zero-leakage capabilities from upstream to downstream. The valves also enable integrity check of seat seals.

Applications

DBB and DIB valves are used in applications where critical isolation is needed to ensure that leakage does not occur. Both valves can be used in a variety of applications and markets, such as LNG, petrochemical, transmission and storage, natural gas industrial processes, mainline and manifold valves in liquid pipelines, and refined products transmission lines.

Another application in which DBB and DIB valves are used is the meter calibration market. Every closed valve in the meter system must seal drop tight. Even a small leak will cause errors in the meter calibration, and the incorrect meter factor will persist until the next proving operation, costing significant sums. Choosing the correct API-verified DBB or DIB valve can help ensure correct calibration almost every time.

Cameron offers a wide range of DBB or DIB valve types and options to fit specific needs. For example, in liquid service near waterways or municipalities, double expanding gate valves with DBB capabilities, such as the Cameron WKM Pow-R-Seal double expanding gate valve, are preferred for critical isolation because they provide a tight mechanical seal simultaneously upstream and downstream, which is normally unaffected by pressure variations or vibrations.

The mechanical wedge action of a double block and bleed plug valve, such as the Cameron GENERAL Twin Seal double block and bleed plug valve, firmly compresses both the upstream and the downstream seals against the valve body, requiring no help from the line pressure to effect a positive seal. Double block and bleed plug valves, which are used often in the transmission and storage markets, provide consistent and provable zero leakage of various fluids.

| Valve Type | Sealing Arrangement | Block and Bleed | Double Block and Bleed | Double Isolation and Bleed | OSHA Double Block and Bleed |

| Two block valves with bleed between | Any valves with bidirectional sealing | Yes | Yes | Yes | Yes |

| Slab gate, through-conduit gate, or both | Pressure energized; downstream sealing only; fixed seats† | No‡ | No | No | No |

| Slab gate, through-conduit gate, or both (DIB-1) | Pressure energized; upstream and downstream sealing† | Yes | Yes§ | Yes§ | No |

| Trunnion-mounted ball valve | Self-relieving upstream sealing and pressure-energized seats† | Yes | †† | No‡‡ |

No |

| Trunnion-mounted ball valve (DIB-1) | Upstream and downstream sealing; pressure energized (e.g., two bidirectional sealing seats)† | Yes | †† | §§ | No |

| Trunnion-mounted ball valve (DIB-2) | Upstream and downstream sealing; pressure energized (e.g., one bidirectional and one unidirectional sealing seat)† | Yes | †† | Only if the bidirectional seat is on the downstream side§§ |

No |

| Floating ball valve | Pressure energized | No‡ | No | No | No |

| Plug | Pressure-energized downstream sealing† | No‡ | No | No | No |

| Expanding plug (DIB-1) | Mechanically energized | Yes | Yes | Yes | No |

| Expanding gate (DIB-1) | Mechanically energized | Yes | Yes§ | Yes§ | No |

† Upstream and downstream refer to pressure source and open-end equipment, respectively, and do not refer to flow direction

‡ Not possible to bleed from valve body, but bleed may be in downstream pipework or pipeline

§ Depending on detailed design of the valve, some valves can have preferred sealing direction, specified sequence of operation, or both

†† Depending on detailed design

‡‡ Downstream seat can provide a second barrier at pressures below the cavity relieving pressure but will not provide a high-pressure barrier

§§ Depending on detailed design and ability to achieve testing per API Spec 6D Section D13