Produce better-quality drilling programs in minutes.

Driving efficiency and collaboration with DrillPlan™ coherent well planning and engineering solutions

Published: 09/24/2025

Driving efficiency and collaboration with DrillPlan™ coherent well planning and engineering solutions

Published: 09/24/2025

Well planning and engineering are complex endeavors, requiring the seamless collaboration of multiple disciplines, rigorous design validation, and real-time adaptability. Enter DrillPlan™ coherent well planning and engineering solutions, a cloud-native application that revolutionizes the well planning process. By harnessing the power of automation and integration, DrillPlan solutions empower teams to collaborate seamlessly and ensure that your well design is continuously coherent, efficient, and optimized for success.

Automation: delivering precision and efficiency at every step

At the heart of the DrillPlan solutions is a commitment to automation, transforming how drilling plans are created, validated, and executed. By automating engineering analysis, data integration, and document workflows, DrillPlan solutions eliminate manual inefficiencies and ensure every plan is built on a consistent, validated foundation.

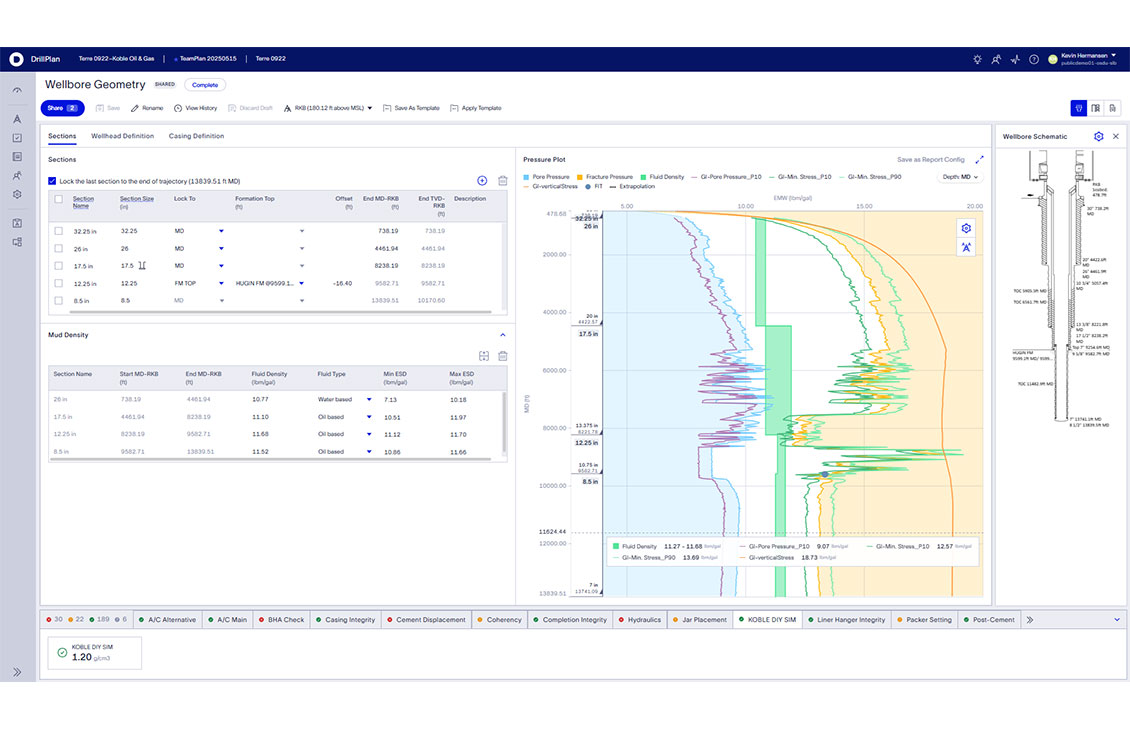

With over 100 automated validations, DrillPlan solutions ensure that every modification to a well design is instantly validated using best-in-class, field proven physics simulators. These validations cover critical aspects like torque and drag, hydraulics, stress analysis, cement displacement, anti-collision, and much more.

For example, if a casing depth is adjusted or a new trajectory is introduced, the system automatically reruns all relevant simulations, flagging issues instantaneously. Whether it's a minor tweak or a significant change to the design, users can trust that their plans will remain compliant and coherent. This proactive approach minimizes the risk of errors while enabling users to plan wells faster.

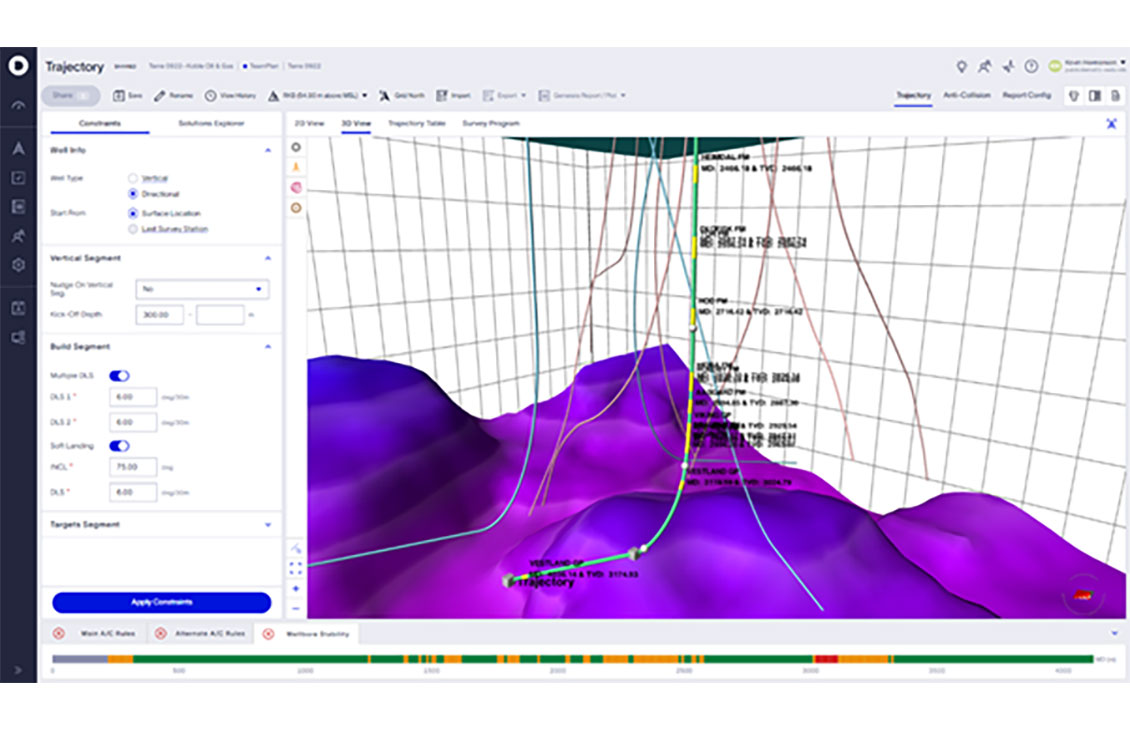

Beyond validation, DrillPlan solutions also offer automated design capabilities. Users can define parameters such as surface location, target depth, and maximum dogleg severity, and the system generates optimized trajectory options that meet these constraints. This empowers users to make informed decisions quickly and efficiently.

Additionally, design elements—like casing depth and drilling parameters—are tied to formation tops. If the formation tops change either through a revised subsurface understanding or through a trajectory change, the system automatically updates all connected design elements, ensuring consistency across the board and significantly reducing the manual effort required.

DrillPlan solutions deliver a unique, comprehensive reporting environment that enables users to produce customized and automated documentation, such as drilling programs, fluid programs, and anti-collision reports within it. Boasting a rich catalog of “dynamic display items”, users can easily add rendered plots, tables, and text strings , that always remain coherent and in-sync with their latest designs, to their documents.

Integration: connecting data, teams, and decisions

While automation enhances the speed and accuracy of individual tasks, integration means that the entire well planning process can operate coherently and collaboratively. DrillPlan solutions achieve this by creating a unified ecosystem for data sharing, analysis, and execution.

Within the application itself, workflows are interconnected. For instance, data from trajectory planning is automatically shared with casing design, torque and drag analysis, and cement hydraulics. This avoids redundant data entry and ensures that updates in one domain are instantly reflected across all relevant workflows. Therefore, no critical detail is overlooked, reducing the risk of errors and improving the overall integrity of the well design.

As part of a unified digital ecosystem, DrillPlan solutions also offer a high degree of openness and extensibility, integrating with subsurface domains and applications, including Petrel™ subsurface software and Techlog™ wellbore software. This integration is particularly powerful in trajectory planning. In the past creating and updating a trajectory involved a lengthy iterative process between the drilling engineer and the subsurface team. Now, the subsurface specialists can publish their datasets from Techlog software and Petrel software to the OSDU® Data Platform. Geomechanics Insights then uses these data sets to create a 3D subsurface model, including a 3D grid of the formation, a 1D mechanical earth model, and associated drilling hazards. This model is then associated with a DrillPlan solutions project enabling real-time updates to the pressure window, formation tops, and hazards when the trajectory is changed. This seamless integration ensures that any changes in the trajectory are instantly reflected in the formation tops, casing shoes, BHA runs, and other related elements. This integration significantly improves well planning efficiency and reduces the process from weeks or days to mere seconds.

Similarly, integration with the Wellbarrier™ well integrity life cycle solution and DrillOps™ intelligent well delivery and insights solutions extend the coherence of plans into operational execution, further enhancing cross-functional collaboration.

DrillPlan solutions also offer a robust set of APIs and extensibility features that enable custom integrations and third-party applications. These APIs, accessible through the Delfi™ developer portal, allow users to send and receive data, broadcast events to external systems, and incorporate custom simulation engines or checks. This openness facilitates real-time updates and synchronization, ensuring that stakeholders always have access to the most accurate, up-to-date information.

A holistic approach to well planning

DrillPlan solutions is built on the principle that automation and integration are not independent features but mutually reinforcing capabilities. Automation ensures that design updates are validated and implemented instantly, while integration ensures that these updates are shared across disciplines and systems without delay.

The result is a holistic well planning process that is faster, more precise, and more collaborative than ever before. By freeing engineers from tedious administrative burdens, DrillPlan solutions enable them to focus on optimizing designs and pushing the boundaries of what’s possible in well planning and engineering.

Thomas Murray

DrillPlan product Champion

Kevin Hermansen

DrillPlan Product Manager