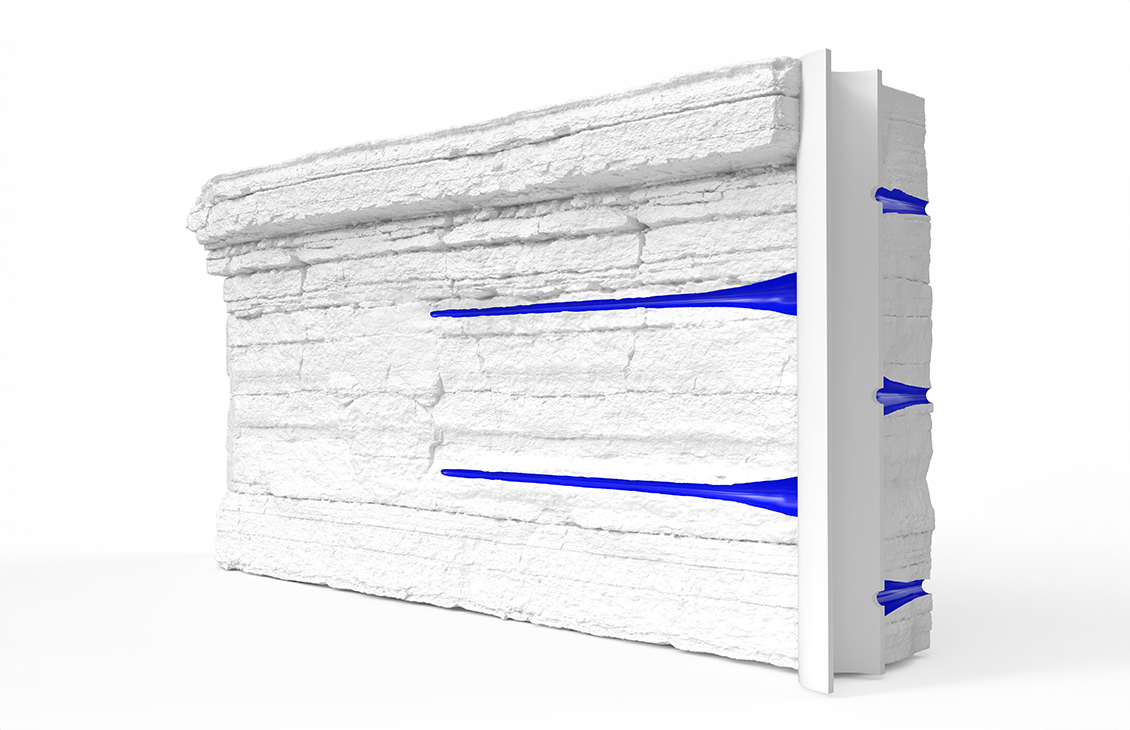

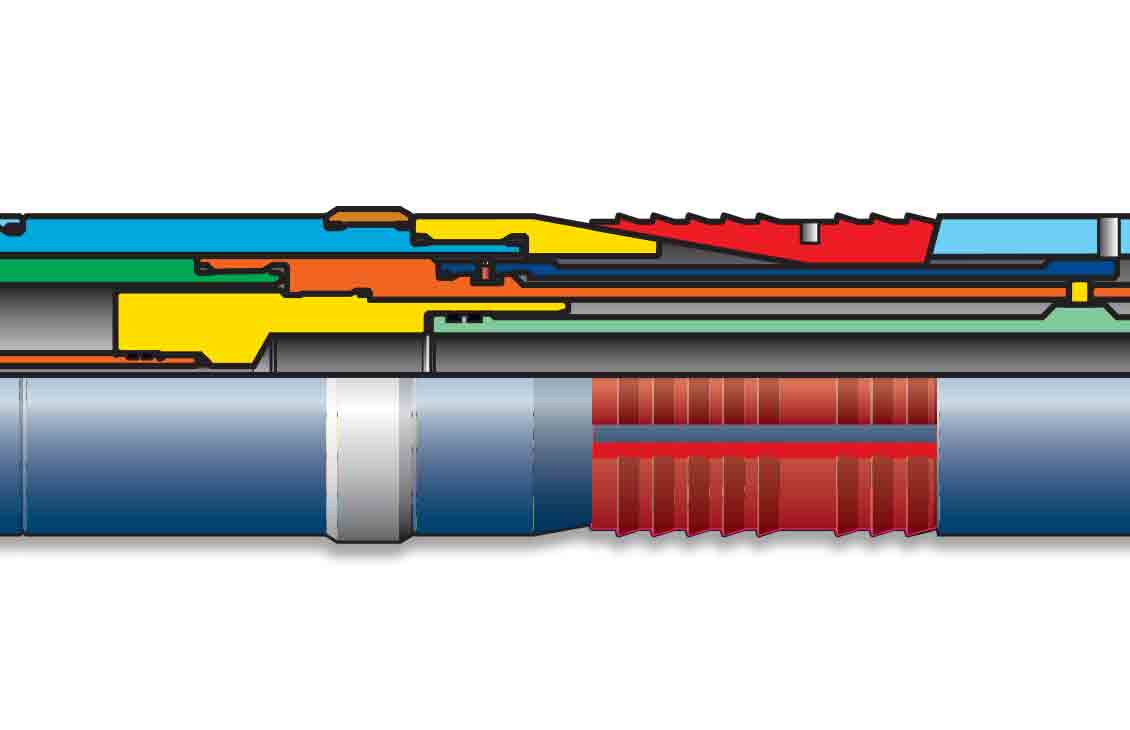

PURE Clean Perforations System

Optimize your well’s performance with custom perforating configurations and precise control of dynamic underbalance.

Minimize perforation damage and boost productivity with the PURE system's optimized dynamic underbalance.