DrillSync automated controls platform synchronizes surface and downhole parameters to improve drilling.

SLB deploys oscillation controller agnostically on third-party rig without modifying existing rig control system

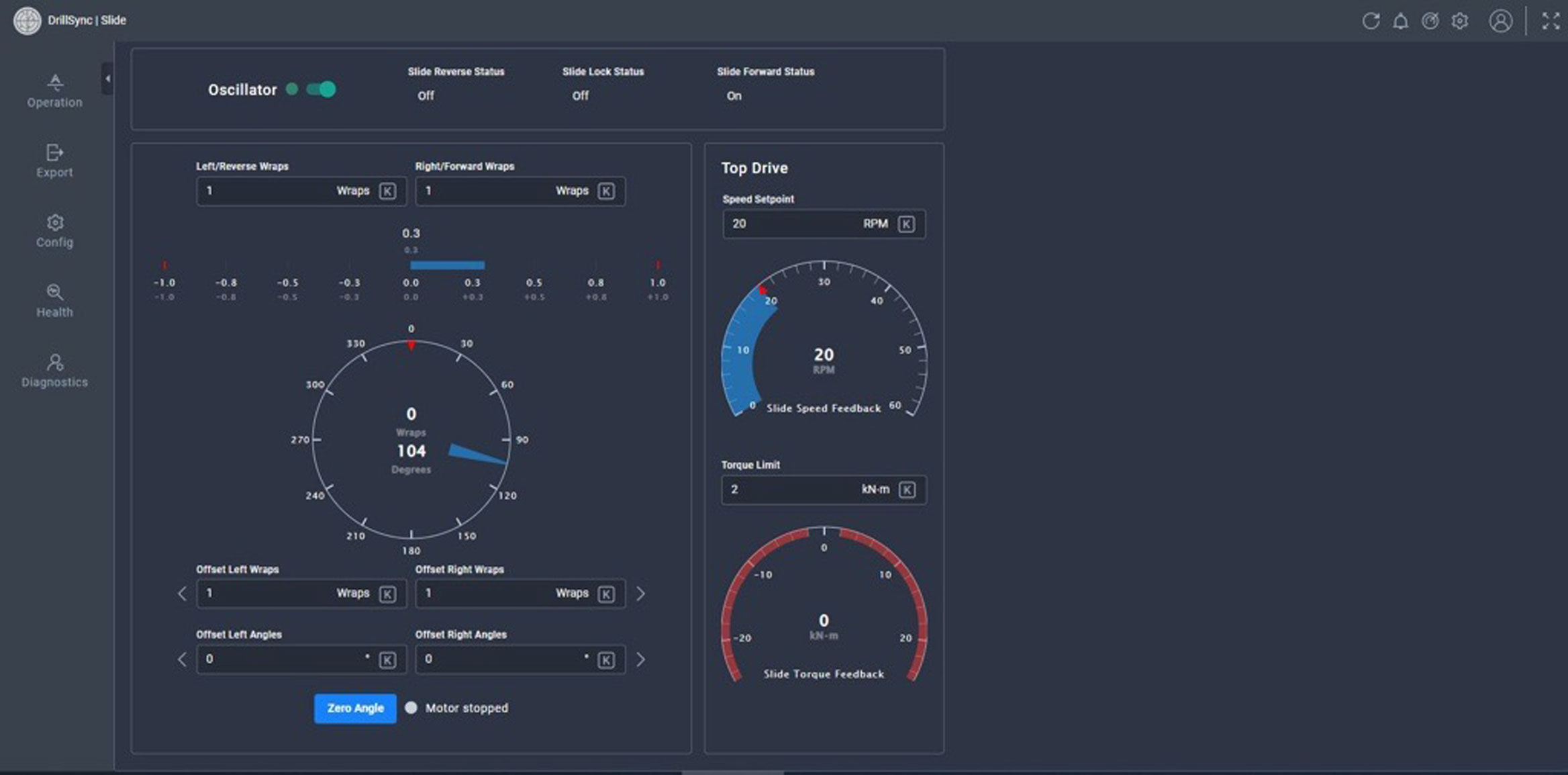

SLB installed its DrillSync™ Oscillator on the operator’s third‑party rig without making a single modification to the existing rig control system while also successfully addressing toolface orientation. In addition to reducing implementation time and costs, this solution enabled the operator to access the full range of the platform's fast-loop applications to increase drilling efficiency, mitigate stick-slip, optimize equipment usage, and leverage data analytics tools to analyze drilling data for insights.

The operator faced two key challenges. The first was integrating the DrillSync Oscillator into their third-party rig. The second was minimizing axial frictional drag on the bit during oscillation to ensure proper toolface orientation.

SLB designed and deployed an agnostic DrillSync Oscillator for the operator that required no interface to the existing rig control system. The DrillSync controller was inserted between the variable frequency drive (VFD) and the third-party rig control system. Additionally, the DrillSync Oscillator automated the oscillation control to decrease friction without changing the downhole toolface. This cost-effective solution reduced downtime and provided the operator access to the range of the platform's fast-loop applications that enhance drilling efficiency, mitigate stick-slip, optimize the use of equipment, and provide data analytics tools to extract insights from drilling data.