Efficiently convert hydraulic energy into mechanical energy for improved ROP and efficiency.

Turbodrill scale removal enables Ecopetrol to access two formations in Colombia

SLB removed scale buildup restricting production in a Colombia well using Neyrfor TTT™ thru-tubing turbodrill.

Remove scale buildup to improve production

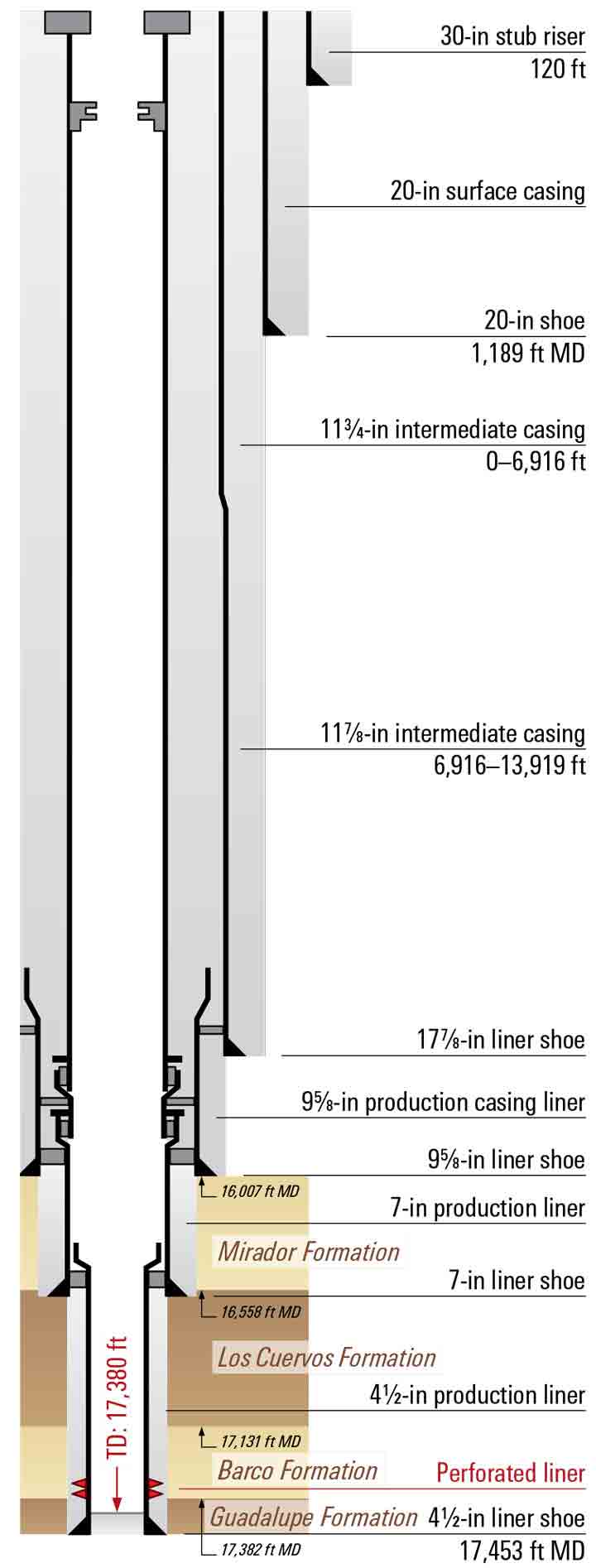

When scale buildup in a well in Colombia’s Cupiagua Sur field restricted production from the Mirador and Barco formations, Ecopetrol attempted to resolve the problem using a scale removal service with more than 300 bbl of 5% hydrochloric acid (HCl). After cleaning out calcium carbonate from 315 ft of production liner at a rate of 36 to 60 ft/h, the jetting assembly was unable to gain further access. Thus, Ecopetrol cancelled the operation and sought another way to complete the scale removal and improve production.

Clean out production liner to TD

SLB used mill scale to run on 2 in coiled tubing. We cleaned out production liner to TD, reduced torque on coiled tubing, minimized HCI expense, provided access to producing formations, and removed scale buildup from 858 ft of production liner at an average rate of 163.43 ft/h.

A 2⅞-in Neyrfor TTT thru-tubing turbodrill attached to a 2-in coiled tubing and driving a high speed mill at more than 2,200 rpm were used in two runs to clean out the 4½-in, 3.958-in ID production liner to TD, giving access to the formations. Two-phase fluid—water-base mud (WBM) injected with N2 and 5% HCl—was used on both runs at a flow rate of 2 bbl of WBM and 1,100 ft3 of N2 per minute. The equivalent flow rate on bottom was between 2.47 and 2.5 bbl/min.

On the first run, which began at 16,472 ft, the turbodrill driving a 3¾-in i-MILL PDC whipstock mill was used to mill 81 ft of scale at an average rate of 54 ft/h before being pulled out of hole. On the second run, a customized 3⅛-in turbodrill was used to mill 777 ft of scale—from 16,553 ft to a TD of 17,330 ft—at an average rate of 207.2 ft/h.

Save time and HCl expense

The Neyrfor TTT turbodrill removed scale buildup from 858 ft of production liner in 5.25 h at an average rate of 163.43 ft/h. Only 60 bbl of 5% HCI were pumped during the turbodrill runs, which when compared with the 300 bbl pumped during the jetting operation, resulted in a lower rate of 36 to 60 ft/h. The turbodrill also put less torque on the coiled tubing than the jetting operation did.