Separate acid gases from produced natural gas without chemicals.

Acid gas removal membranes revolutionize CO2 management for EOR operations, Permian Basin

Cynara™ H2S and CO2 separation membranes have provided Kinder Morgan with an energy-efficient modular solution for bulk CO2 removal from natural gas. The operator is now recovering high-purity CO2 for enhanced oil recovery (EOR) while simultaneously reducing opex and generating a revenue stream from significant natural gas liquids (NGL) recovery.

Kinder Morgan’s SACROC facility in Texas was designed to treat natural gas containing limited quantities of CO2, using the Benfield and amine processes. As time went by and gas production increased, the facility could not cope with the growing and variable quantities of CO2.

Traditional amine treatment systems for CO2 removal were not viable because of the prohibitively large size required for such high CO2 concentrations. On the other hand, reinjecting the entire gas stream without processing it would lead to suboptimal EOR performance (because of reduced miscibility) and the loss of valuable NGL. After a thorough assessment of various options, Kinder Morgan chose membrane technology for its multiple benefits:

- High-purity CO2 is recovered at elevated pressures, reducing reinjection costs.

- Natural cooling of gas in the membrane process results in NGL production, providing a significant revenue stream.

- The modular and compact technology eliminates exposure to solvents, reducing HSE risk.

- Capex and opex are lower compared with other technologies.

Highly selective Cynara membranes provided the ideal solution for bulk CO2 removal. Thousands of hollow fibers made of a cellulose triacetate (CTA) base material are packaged within each cylindrical membrane element. As pressurized feed gas flows along the fiber bundle, CO2 preferentially permeates to the bore side of each fiber. This permeate flows out at the end of the fiber and is collected for EOR, while the hydrocarbon-rich nonpermeate gas continues through the plant for further processing.

By enabling recovery of high-purity CO2 at elevated pressures, Cynara membranes have reduced compression requirements for reinjection. The methane-rich nonpermeate stream is processed using a smaller amine system to produce fuel gas for facility operations. The vertical membrane housing design enables natural drainage of condensed hydrocarbons, facilitating recovery of valuable NGL.

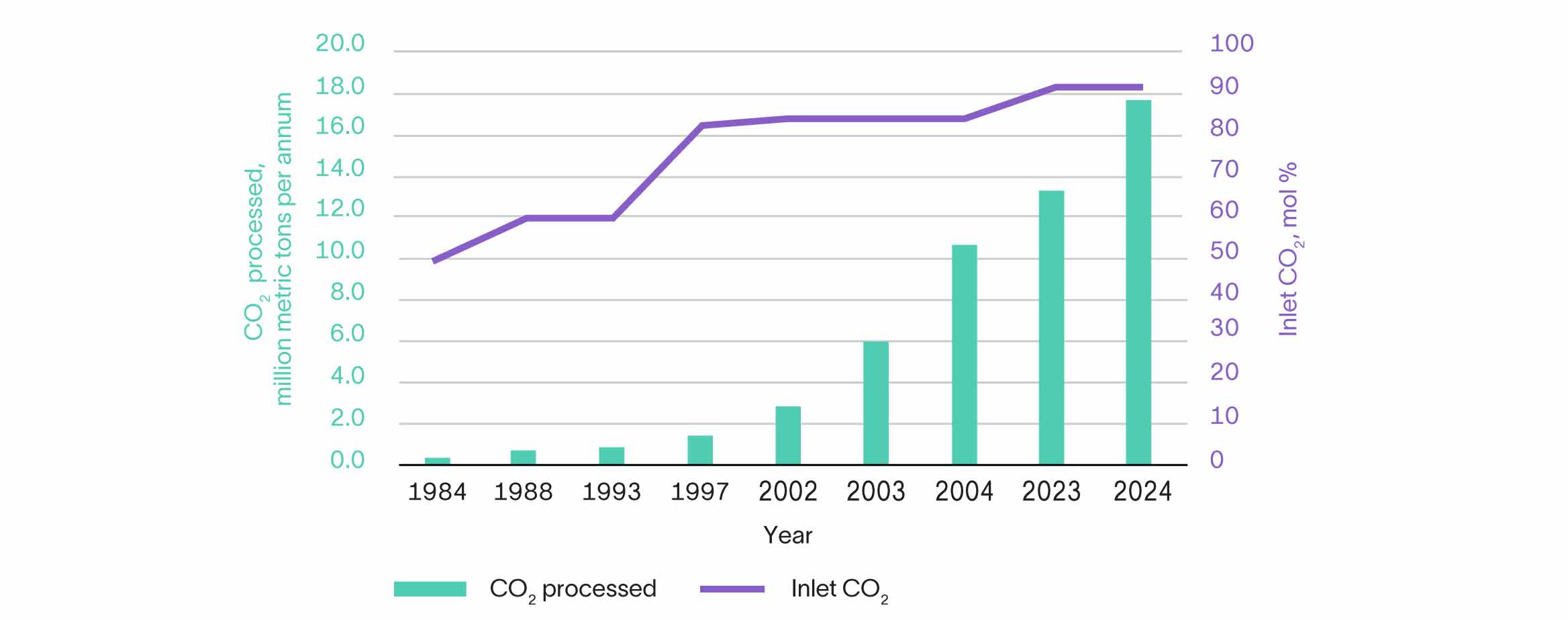

Starting with 50 MMcf/d of gas containing 40–60% CO2, the membrane plant gradually expanded to handle 750 MMcf/d and 91% CO2. In addition, approximately 250 MMcf/d were being processed by spiral wound cellulose acetate (CA) membrane technology from a third party. After a study found that horizontal Cynara membranes demonstrated about 20% incremental NGL recovery and 40% more capacity, Kinder Morgan switched to using Cynara membranes exclusively.

Supporting one of the largest EOR operations in the world—producing ~20,000 BOPD—the SACROC plant currently processes 1,000 MMcf/d of natural gas. The membrane system removes 17.7 million metric tons of CO2/year, resulting in the additional recovery of 18,000 bbl/d of condensate, which provides a substantial incremental revenue stream. Moreover, the high-purity CO2 recovered from the membrane system has reduced the need to purchase pure CO2, significantly lowering opex. The success of the SACROC facility over the past 40 years has made it a showcase for the EOR industry, inspiring the adoption of Cynara membrane technology in multiple EOR projects across Texas and Louisiana as well as offshore Brazil.