Tackle scale, decontaminate naturally occurring radioactive material (NORM), and decommission with efficiency.

Comprehensive barium sulfate scale treatment restores subsurface safety valve operability

The custom-designed treatment addressed the limitations of low reservoir pressure and unique scale characteristics to restore production while minimizing environmental impact.

Producing from a high-permeability 346-m-long [1,135-ft-long] horizontal interval, a North Sea well was completed with sand screens and contains a tubing-retrievable, surface-controlled subsurface safety valve (SCSSV). Production was initially supported by seawater injection, followed by a mixture of seawater and produced water. Since water breakthrough, barium sulfate (BaSO4) scale has presented challenges; it is caused by mixing of the injection water, which has high sulfate content, and formation water containing barium. Water cut is currently >90%.

When the SCSSV became stuck in the open position, BaSO4 deposition was suspected as the likely cause. The consequent well integrity risk led to shutting in the well and loss of production. The operator planned to deploy a water-based sulfate scale dissolver by bullheading from the surface. BaSO4 scale dissolvers are typically chelants, which grasp metal ions tightly so that they cannot be easily liberated by other substances. The process is relatively slow, with effective chelation taking up to 24 hours at the downhole temperatures typical in this field.

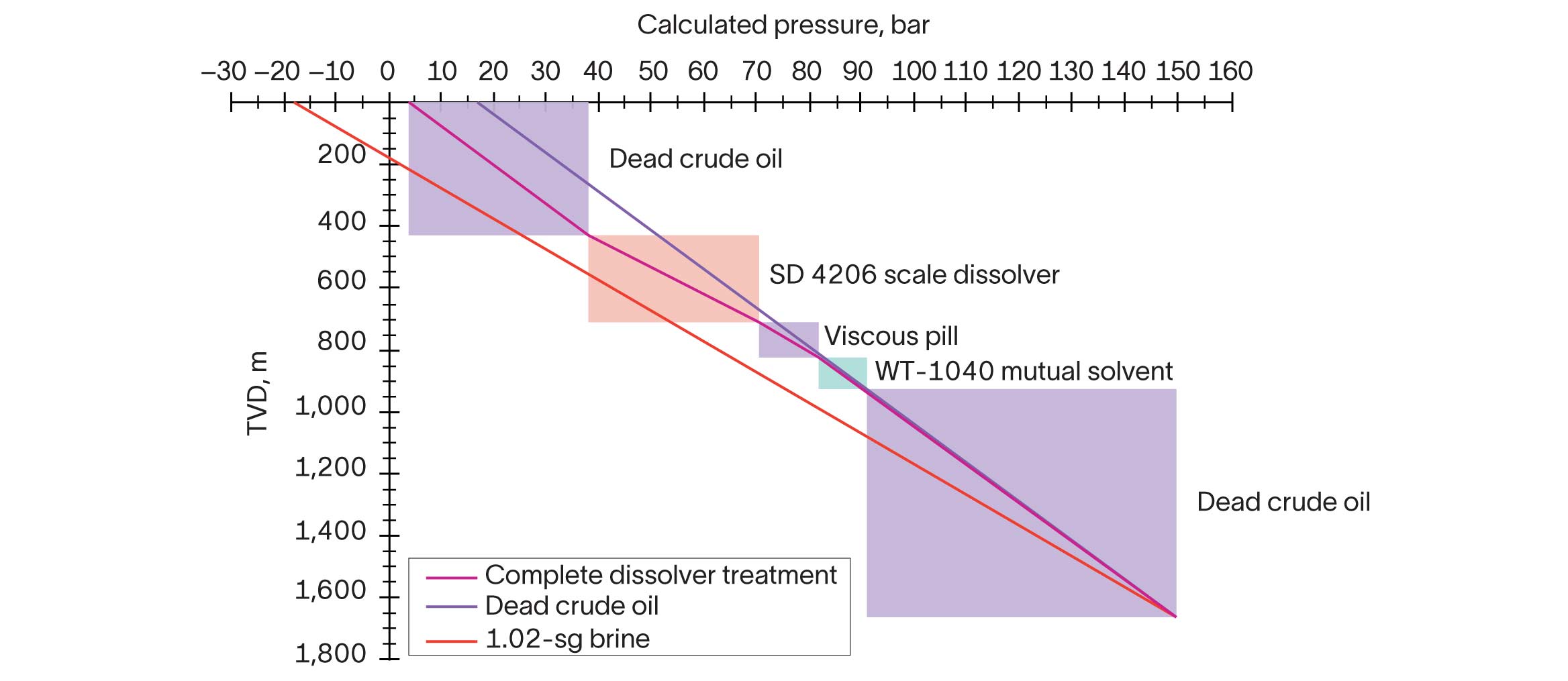

However, the reservoir pressure was too low to withstand a tubing column of water-based fluids with a density >1 g/cm3. Because of the resulting fluid loss, the scale dissolver would not stay in place across the SCSSV; instead, it would sink below the target area. Even if lower-density dead crude oil was used to displace the water-based well fluid, the denser aqueous-phase scale dissolver placed across the SCSSV—above the lighter crude—would immediately fall through the oil phase. A strategy was required to effectively deploy the scale dissolver and hold it in place for up to 24 hours.

SLB recommended placing a suitable viscous pill on top of the low-density oil phase in the lower production tubing. The pill would hold the dense scale dissolver across the safety valve, preventing the oil phase from rising and the aqueous-phase dissolver from sinking away.

A seven-stage remediation operation was designed and implemented. All risks associated with the planned intervention were assessed by the operator and mitigation strategies and actions put in place.

- Displacement: Wellbore fluid in the production tubing was displaced with dead crude oil.

- Preflush: Mineral scales in oil wells are often entrained in crude oil or materials such as asphaltenes or wax. Because scale dissolvers are more efficient on a water-wet surface than on an oil-wet one, preflushing with an appropriate solvent is recommended. A 4-m3 pill of the popular WT-1040™ mutual solvent—which has a density <1 g/cm3 but slightly more than that of the crude—was used to clean the surface of the scale in the SCSSV.

- Viscous pill: Next, a 4-m3 pill of a proprietary SLB dispersible xanthan gum viscosifier was deployed to hold the heavier scale dissolver column across the safety valve. The viscosifier is predispersed in a water-miscible carrier fluid that helps prevent lumps or “fish eyes” so that the polymer rapidly and smoothly viscosifies the slurry.

A 15,000-ppm solution of the viscosifier in NaCl brine treated with a proprietary SLB oxygen scavenger (to minimize corrosion by removing oxygen from the brine) was formulated to provide adequate rheological properties. The complete viscous pill was shown to be completely dispersible by seawater dilution, a key requirement when producing the pill back to surface. It was sized to cover an approximately 100-m-long [328-ft-long] interval in the production tubing and placed significantly above the production zone to avoid potentially plugging the sand screens.

- Scale dissolver: SD™ 4206 scale dissolver is based on the latest environmentally acceptable chelating agents and provides optimal efficiency and dissolving capacity. Compared with traditional ethylenediaminetetraacetic acid (EDTA) dissolvers, SD 4206 scale dissolver displays excellent dissolution activity, even at lower temperatures. Deploying 10 m3 of the scale dissolver was intended to provide an approximately 270-m-long [885-ft-long] column above the SCSSV, compensating for the possibility of the viscous pill slipping downward during the 24-h shut-in period.

- Displacement: Dead crude oil was added on top to maintain the lightest column possible.

- Shut-in: Conventional sulfate dissolver treatments alternate short (4-h to 6-h) shut-in stages with small displacement stages to provide fresh dissolver and limit local chemical saturation on the scale surface, which occurs in static environments. However, for this well, gravity-induced slumping of the 270-m scale dissolver column was projected to provide continuous replacement of the dissolver at the SCSSV over a single continuous 24-h shut-in period.

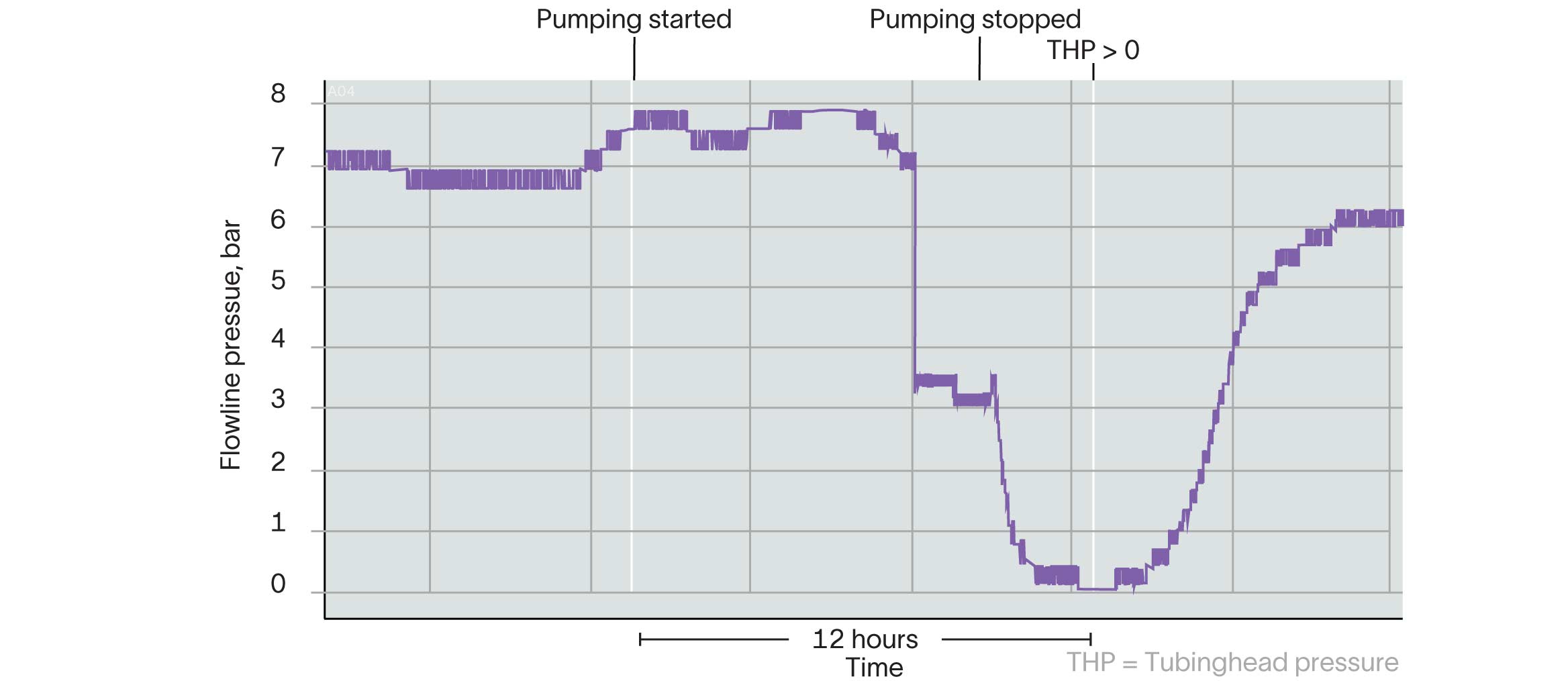

- Flowback: The well was restarted the following day, and the flowback removed the oil, various additives, and scale particles from the wellbore.

Following the flowback period, SCSSV operability was tested and a successful test was obtained on the fourth attempt. Subsequently, the well was squeezed with scale inhibitor and placed back on production. The SCSSV was retested after about 7 weeks and the test was again successful, proving the efficacy of the treatments.