Address the challenge of paraffin deposits, which form when hydrocarbons depressurize and cool.

Targeted chemical treatment triples interval between hydrocyclone shutdowns offshore Qatar

An SLB chemical formulation eliminated schmoo and inhibited additional deposits, streamlining maintenance of equipment for produced water treatment on three offshore platforms.

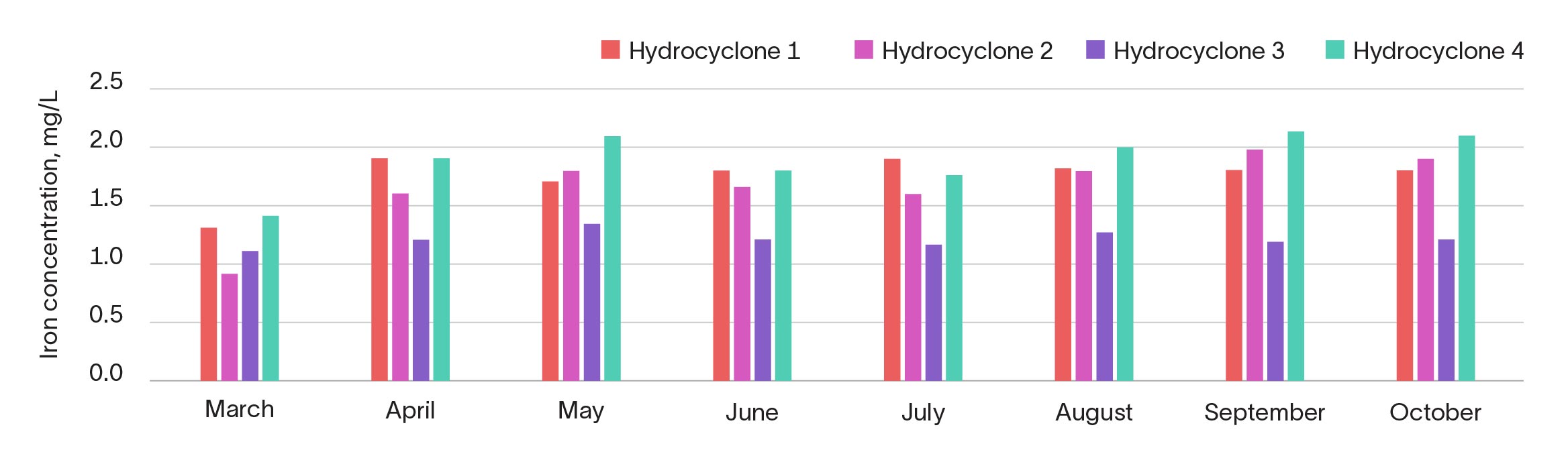

An operator produces an average of 345,000 bbl of oil per day from nine platforms offshore Qatar. Deposition of solids and schmoo in the hydrocyclones was hindering treatment of produced water. Schmoo is a viscous, tar-like substance that consists primarily of oil-coated inorganic particles (such as iron sulfides and sand) and organic matter. Every 2–3 months, one of the hydrocyclones had to be stopped for acid cleaning, a costly process that also presented logistical challenges in the offshore environment.

A chemical inhibitor was required to mitigate deposition. After conducting several laboratory tests, SLB proposed its CC-50111 schmoo remover, and the operator agreed to a 3-month offshore trial to assess the product’s benefits and performance.

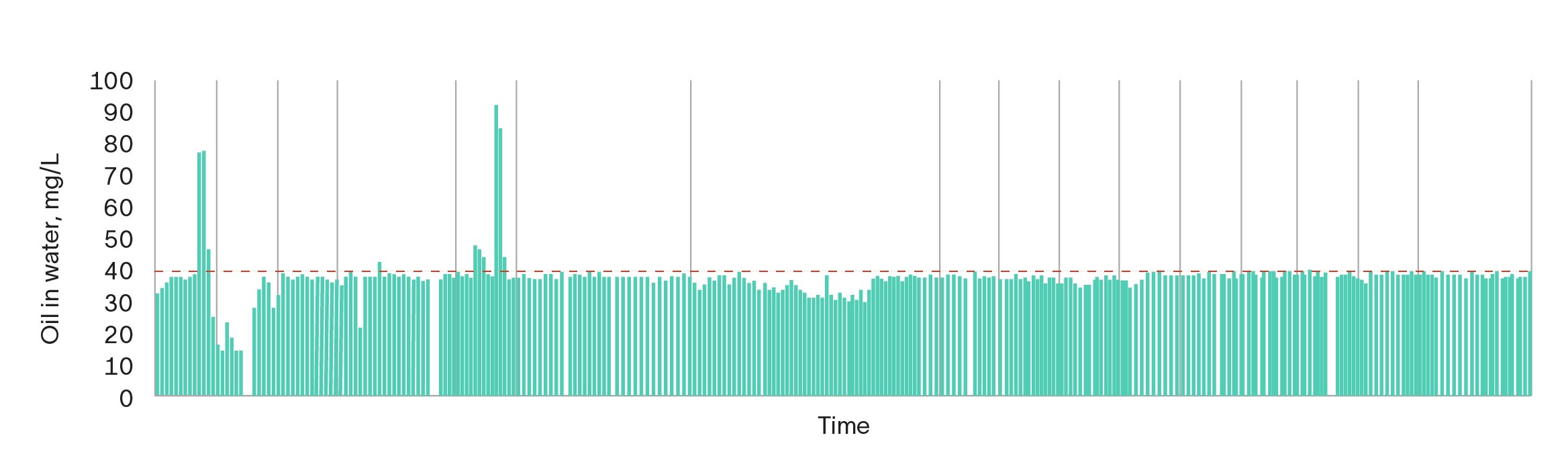

CC-50111 was injected continuously downstream of the production separator on the three main platforms. Because schmoo does not consist of just one component, it is challenging to remove. The SLB product works by mobilizing or dissolving all the solids that create the plugging and deposition issues. Solids are eliminated in the water phase, while hydrocarbons are returned to the oil phase. Once the level of schmoo in the system decreased to acceptable limits, a lower chemical dosage was used to prevent further deposition and maintain a clean operation.

CC-50111 provided excellent cleaning and increased the efficiency of the hydrocyclones and induced-gas flotation (IGF) unit from 60% to 90%. Oil-in-water (OIW) readings were maintained within acceptable limits. As a result, the operator has continued CC-50111 injection, and the interval between hydrocyclone cleanups has increased from 3 months to as much as 9 months.