Delivers power for downhole tools, enabling more efficient and battery-free intervention operations.

Coiled tubing solution cuts offshore intervention time by 83%

Using the powered downhole measurements system of ACTive™ real‑time downhole coiled tubing services, an operator completed a full intervention workflow—cleanout, logging, shutoff, and reperforation—on a single conveyance. This reduced offshore exposure by 60 hours, accelerated production by four months, and saved 7.4 days compared to conventional methods. The workflow also minimized equipment footprint and carbon emissions.

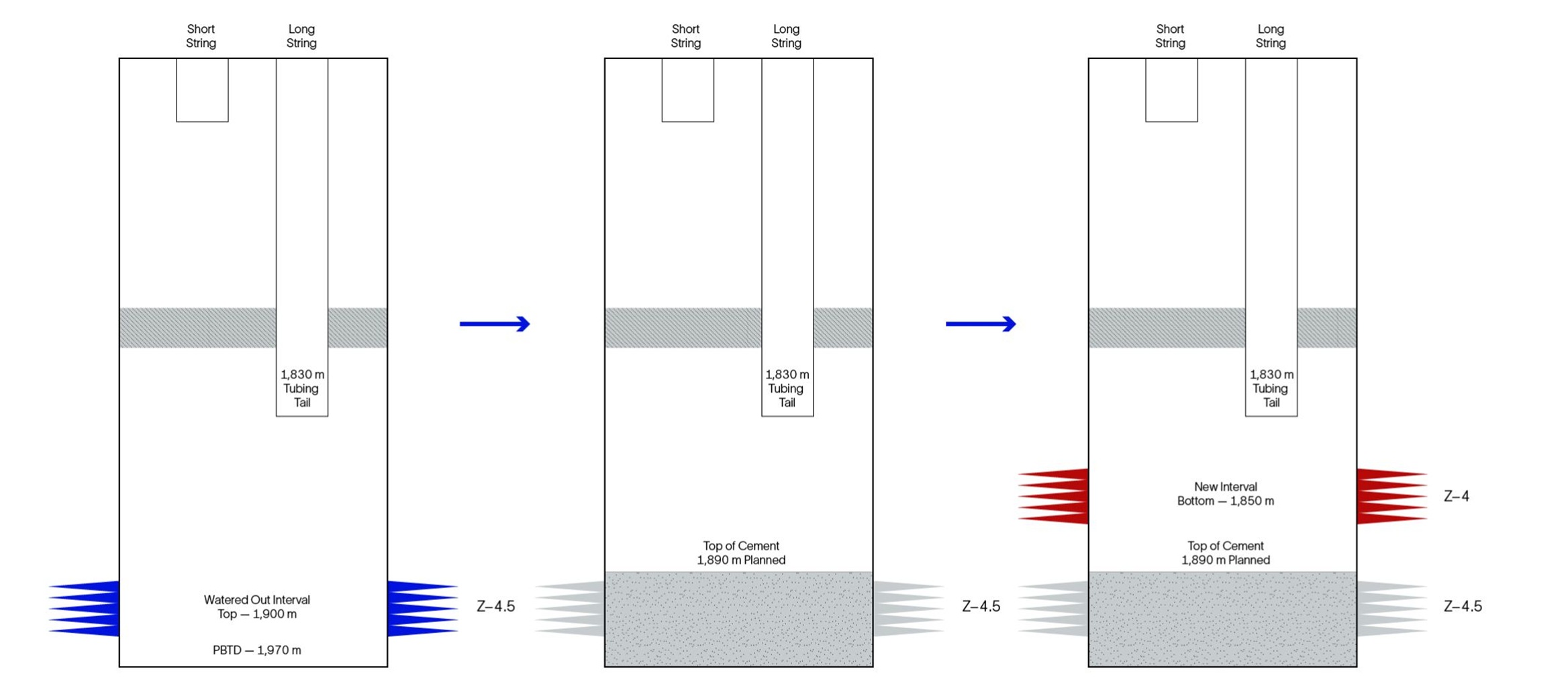

Offshore platforms in the Malay Basin face increasing challenges in restoring production from mature gas wells. Declining reservoir pressure and water encroachment often lead to liquid loading, which can shut in wells prematurely. To unlock behind‑casing opportunities in watered-out zones, operators must confirm saturation levels and isolate depleted intervals before adding new perforations.

Conventional intervention methods require multiple conveyance systems—slickline, wireline, and coiled tubing—resulting in complex logistics, heavy lifts, and extended operational time. These challenges are amplified on remote platforms with limited deck space and crane capacity. A safer, more efficient solution was needed to reduce offshore exposure and streamline operations.

The intervention leveraged ACTive powered downhole measurements system to enable advanced production logging tools such as Pulsar™ multifunction spectroscopy service to be conveyed via coiled tubing. This allowed the entire workflow—cleanout, saturation logging, water shutoff, and reperforation—to be executed with a single conveyance.

Key highlights

- ACTive powered downhole measurements system eliminated battery subs, reducing the BHA length to 8.5 m.

- The toolstring fit within the lubricator stack without pressure deployment, avoiding slickline rig-up and reducing health and safety risks.

- ACTive powered downhole measurements system provided continuous surface power, enabling high-resolution pulsed neutron spectroscopy logging under both static and flowing conditions.

- Nitrogen lifting during logging enabled data acquisition in subhydrostatic conditions, which would not have been possible with wireline.

- Cementing was performed safely through the hybrid electro-optical cable with optimized flow rates, confirming cable integrity postoperation.

Operational impact

- 83% time savings compared to conventional pressure deployment methods.

- 60 hours of high-risk offshore activity eliminated, including mechanical lifting and pressure exposure.

- Production accelerated by four months, with reduced planning and logistics.

- Smaller equipment footprint and lower carbon emissions, with better utilization of wireline resources.

- Ten wells completed in Malaysia using this workflow over two years, enabling saturation logging and full intervention workflows on a single conveyance.

In one representative case, the process from cleanout to pull out of hole (POOH) took only 9.2 days, compared to 16.6 days with traditional stacked completion—saving 7.4 days.

For more information, read SPE-218364-MS.