Higher ROP and durability to save time and costs

Serrated diamond element bit drills complex section in a single trip, saving 9 hours

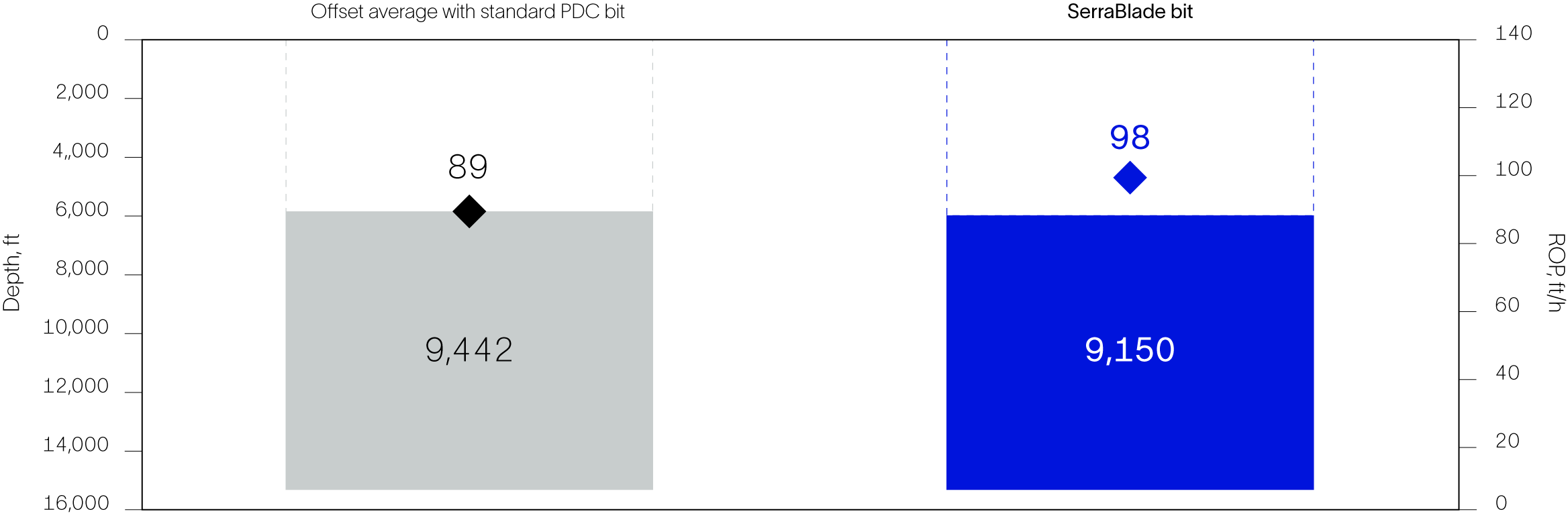

By using the SerraBlade™ serrated diamond element bit in an onshore well in the UAE, 9,150 ft of an 8.5-in section were drilled in a single run, starting from near-vertical and ending at the 6,000-ft lateral. With its multiridge cutting tip, this innovative bit demonstrated greater toughness against impact, yielding a 10% increase in ROP versus the offset wells’ average, saving 9 hours of drilling time and associated costs.

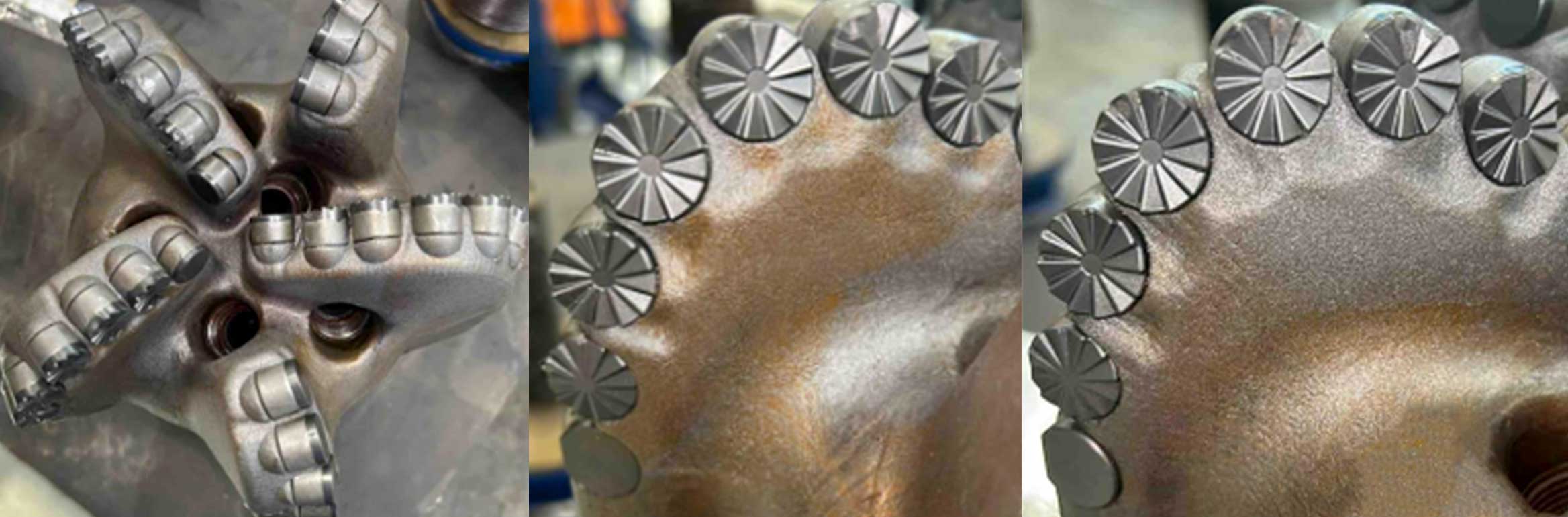

In a collaboration between SLB and an operator, the project focused on accelerating the UAE’s unconventional oil and gas program by improving drilling performance. However, the formation posed challenges for conventional PDC bit performance, given the interbedded formation dominated by limestone, where reduced cutting efficiency and increased cutter-breakage risk were significant risks. As a result, superior drillbit and cutter technology was critical to enabling faster ROP, mitigating cutter-breakage risks, and reducing drilling time and costs.

The SerraBlade bit delivered efficient rock-cutting action, drilling 9,150 ft of the 8.5-in section in a single run, from near-vertical to the end of a 6,000-ft lateral. The drilling ROP was 98.4 ft/h, which was 10% higher than the offset wells’ average of 89 ft/h, resulting in 9 hours saved and related costs. The cutters were positioned strategically on the nose and shoulder of the bit, which are zones prone to high impact and wear. Their serrated shape provided a continuous shearing and crushing action to break the carbonate rock more efficiently, while the multiridge cutting tip of the SerraBlade bit reduced cutter-breakage risk, helping to keep the cutter sharp while drilling the complex interbedded limestone formation.