Improving BHA tool reliability while enabling PDC cutters to stay sharp for faster, longer drilling.

Accelerating drilling efficiency: 8.5 days saved with Suppressor dampening tool integration

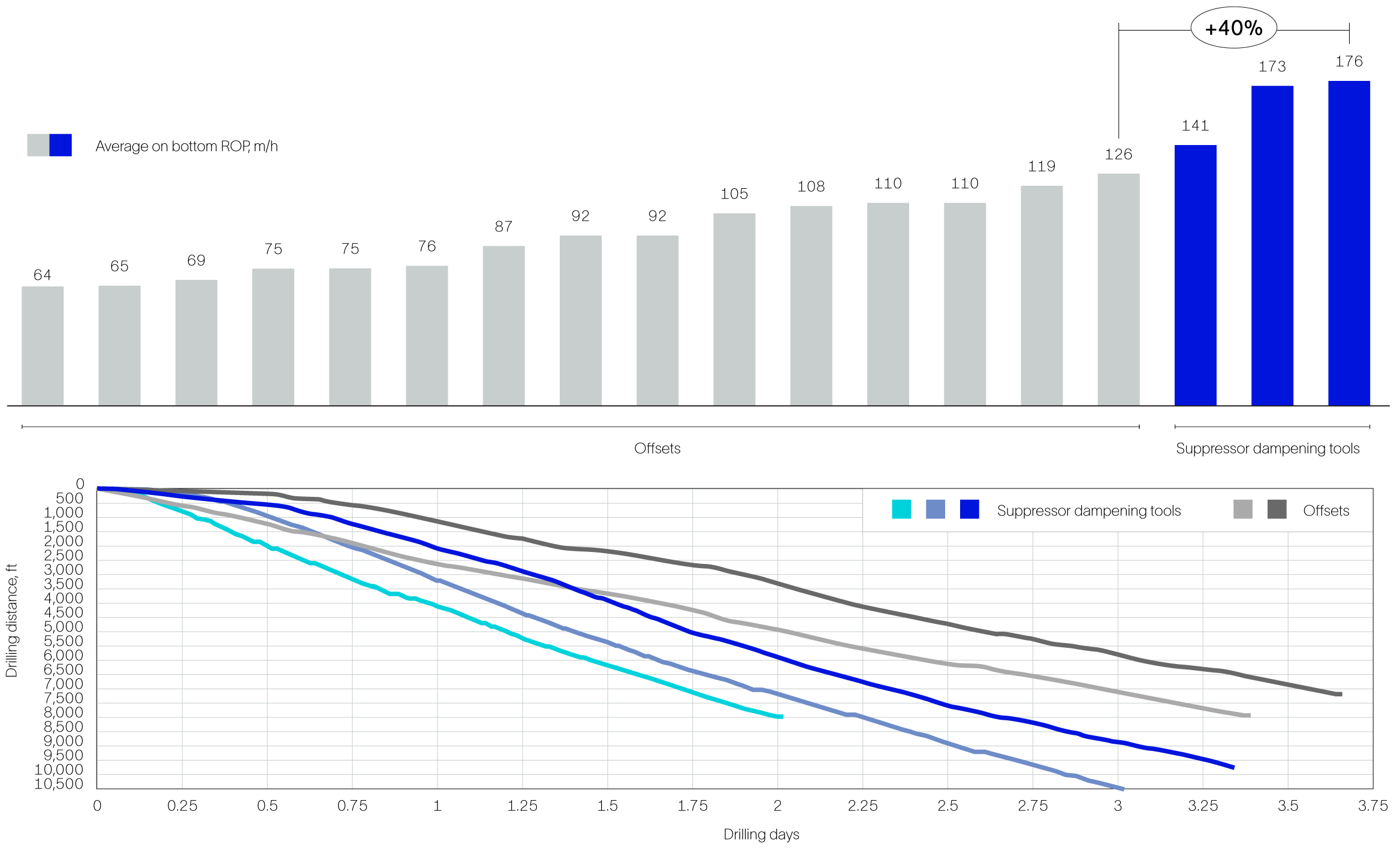

Leveraging an integrated BHA featuring the Suppressor dampening tool and the PowerDrive vorteX™ high-powered rotary steerable system, the customer drilled three wells from shoe to TD in a single run, eliminating 8.5 days of rig time and setting a new benchmark for drilling efficiency.

In the demanding formations of southern Oman where high-density rock and severe downhole vibration threaten performance, the customer pursued a bold objective: cut costs and elevate drilling efficiency.

By integrating the Suppressor dampening tool with the PowerDrive vorteX system, the customer drilled three wells from shoe to TD in a single run, saving 8.5 days of rig time. The Suppressor dampening tool effectively minimized high-frequency torsional vibration and overall shock, enabling smoother, more stable drilling and expanding the drilling operating window. This translated into improved on-bottom ROP and zero tool failures throughout the run. Notably, the fastest well was drilled in just 2 days, finishing nearly 5 days ahead of the scheduled AFE completion date.