Optimizing Artificial Lift

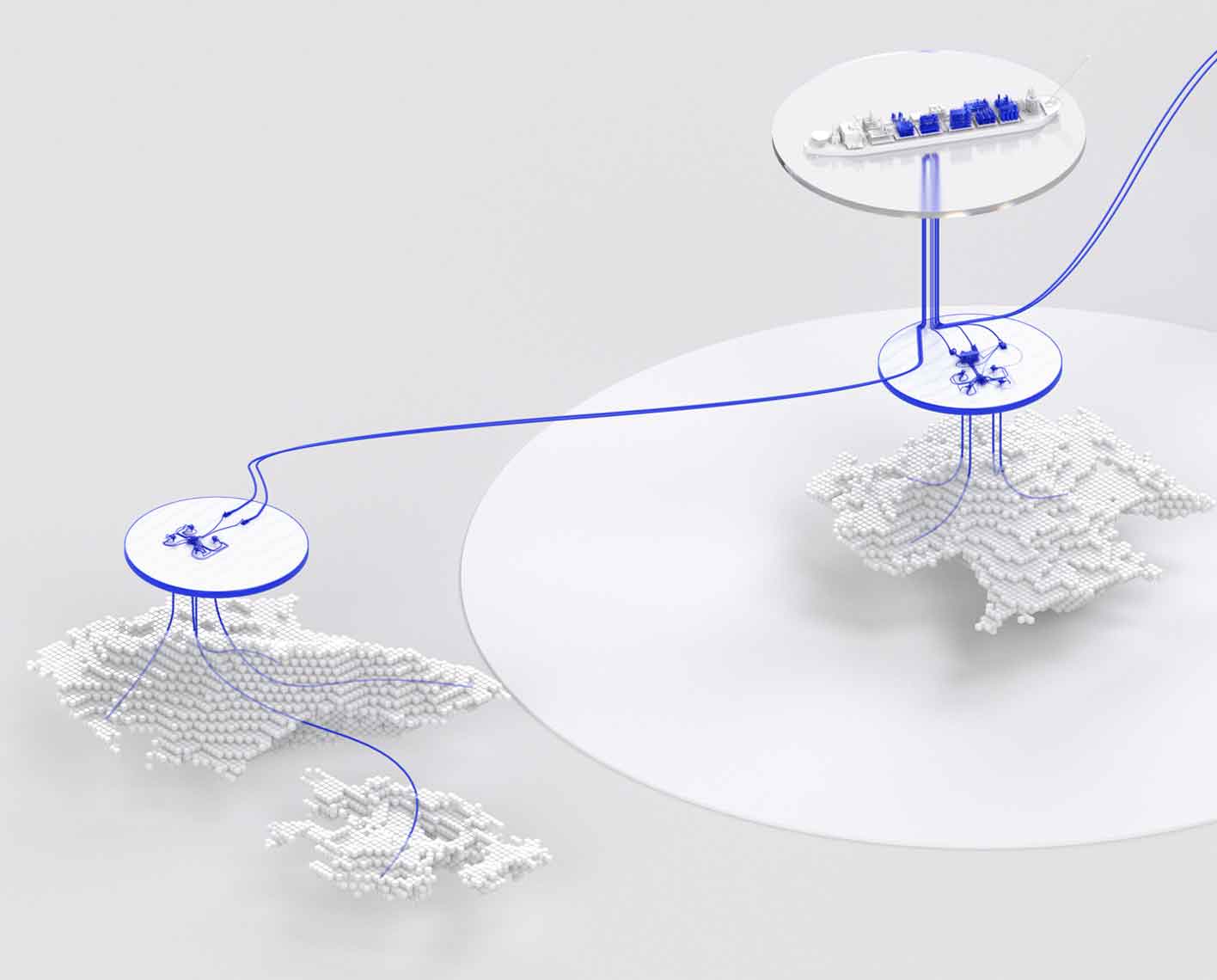

Software, production chemicals, and increasingly autonomous services for optimal artificial lift operations

Derive maximum benefit from a comprehensive portfolio

Our artificial lift solutions portfolio includes specialized expertise and complete equipment packages for every flow rate, including rod lift pumps, progressing cavity pumps (PCPs), hydraulic stroking units, electric submersible pumps (ESPs), horizontal surface pumps, and gas lift systems. This equipment can be further customized with an extensive selection of options, such as gas handling and separation devices, rigless ESP replacement systems, surveillance and remote intervention choices, lift control systems, autonomous optimization of chemical treatment programs, and more.