Increase zonal isolation assurance in your well.

Invizion Evaluation Service Confirms TOC and Identifies Position of Losses in Salt Section, Gulf of Mexico

Published: 03/30/2016

Invizion Evaluation Service Confirms TOC and Identifies Position of Losses in Salt Section, Gulf of Mexico

Published: 03/30/2016

Operator needed to confirm integrity of a subsalt appraisal well

While salt structures are effective traps for oil and gas, they are also notorious for their operational challenges. In deepwater cementing operations, salt creep can create unusual bonding and nonuniform loading on the casing—potentially eventually causing the tubulars to collapse. If fractures occur in homogeneous salt sections, the resulting losses make it difficult to evaluate the position of the fractures and their effect on TOC placement.

Because of these challenges, the operator required TOC assurance as part of the process of planning future development wells. While reviewing several offset wells in an extensive exploration campaign, the operator decided to reconfirm the condition of a section of an older appraisal well with 14-in casing.

Conventional methods estimated TOC by analyzing only surface parameters, which is insufficient due to the compressibility of the synthetic-base fluid used to drill this section and the presence of losses that affected the surface pressure parameters. In addition, the well design created a long, narrow annulus, which acted as a choke and prevented mud from circulating back to surface, initiating losses. Special casings with thick walls were also used for the well construction, making it more difficult to interpret the sound reflection behind the casing.

The operator engaged Schlumberger for Invizion Evaluation well integrity evaluation service, which collects, integrates, analyzes, and interprets data from multiple areas of this section of well construction, and then generates recommendations for future sections in similar conditions.

Invizion Evaluation service exceeded conventional cement evaluation capabilities

Previous job data showed the well had been cemented with losses through a clean salt section to a measured depth of 19,923 ft [6,073 m]. The TOC was initially estimated to be at 18,640 ft [5,681 m].

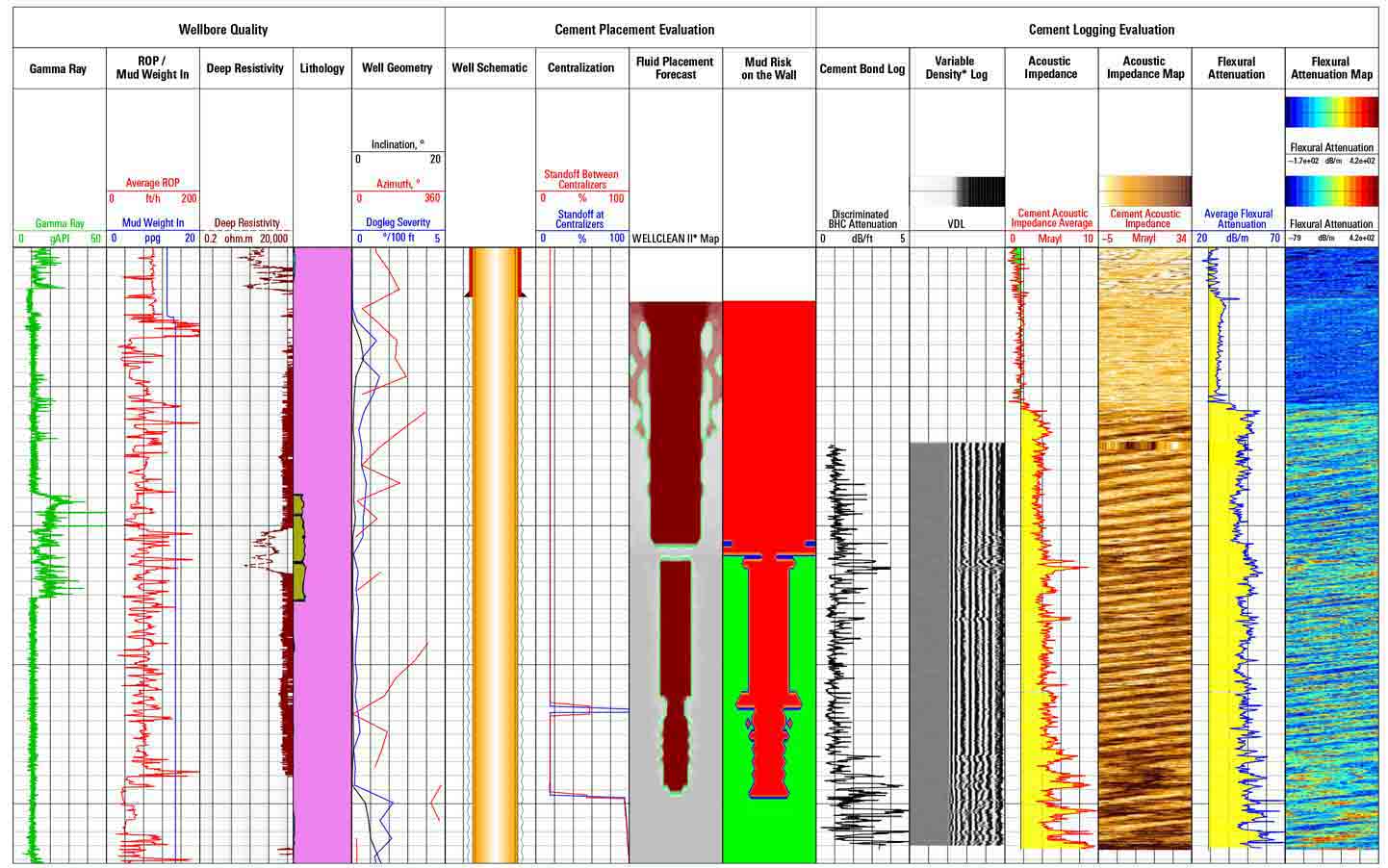

Schlumberger recreated the lithology profile based on available openhole data and identified the position of losses in the open hole, and then conducted cross-domain data evaluation using openhole, cement placement, and cased hole logs. Advances in cementing simulations helped the team account for the synthetic-base mud compressibility effect, losses, and flat fluid interfaces in the placement simulator. The result of the new analysis showed that contaminated cement was placed up to 16,160 ft, with the partial losses at 17,200 ft—correlating with the well's position in the salt body.

Operator improved cementing practices for future field wells

The Invizion Evaluation service helped the operator accurately confirm the TOC and understand the true cause of losses after conventional analysis could not. After the evaluation, Schlumberger provided detailed recommendations, including analyzing openhole data and identifying the loss zone prior to cementing to aid in evaluation—enabling the operator to develop a lost circulation strategy, improve job performance, and enhance cement evaluation for future development wells in the project.

Challenge: Identify loss zones and verify cement placement in a salt section where conventional cement evaluation technologies cannot function well.

Solution: Use Invizion Evaluation well integrity evaluation service to integrate job data and analyze openhole data in the salt section to identify position of losses, zonal isolation, and top of cement (TOC) in a subsalt appraisal well with 14-in casing.

Results: Accurately placed TOC at 16,160 ft [4,926 m] and identified partial losses at 17,200 ft [5,243 m] in the salt section to correct the conventional interpretation that had incorrectly estimated TOC at 18,640 ft [5,681 m].