PowerDrive Xcel system provides the power to place wells accurately with superior wellbore quality.

PowerDrive Xcel RSS with Gyro Technology Saves 5 Days off of AFE, Offshore Russia

Published: 03/02/2018

PowerDrive Xcel RSS with Gyro Technology Saves 5 Days off of AFE, Offshore Russia

Published: 03/02/2018

Perform kickoff with rathole extension while reducing collision risk due to tracking casing

In a field offshore Russia, an operator wanted to kick off an existing wellbore to drill a new ERD well. The operation typically requires 3 different BHAs: one to set the whipstock and mill the window, followed by a motor BHA to perform the kick off, and a third BHA embarking an RSS to drill the rest of the section.

Couple advanced whipstock technology with precision gyro steering capability

Schlumberger recommended using the TrackMaster Select system and a PowerDrive Xcel RSS. The mill behavior and cutting structure of the TrackMaster Select system were modeled to provide the optimal configuration for drilling the required window to exit casing at the planned dogleg severity of 2.5°/30 m. The TrackMaster Select system was set at 81° inclination, which is the highest achieved by a 13 3/8-in TrackMaster comprehensive whipstock sidetracking solution.

The PowerDrive Xcel RSS would incorporate gyro technology, enabling the BHA to kick off from the whipstock, despite the magnetic interference caused by the casing and the whipstock, and then precisely follow the planned trajectory to TD.

Eliminated planned trip while mitigating magnetic interference

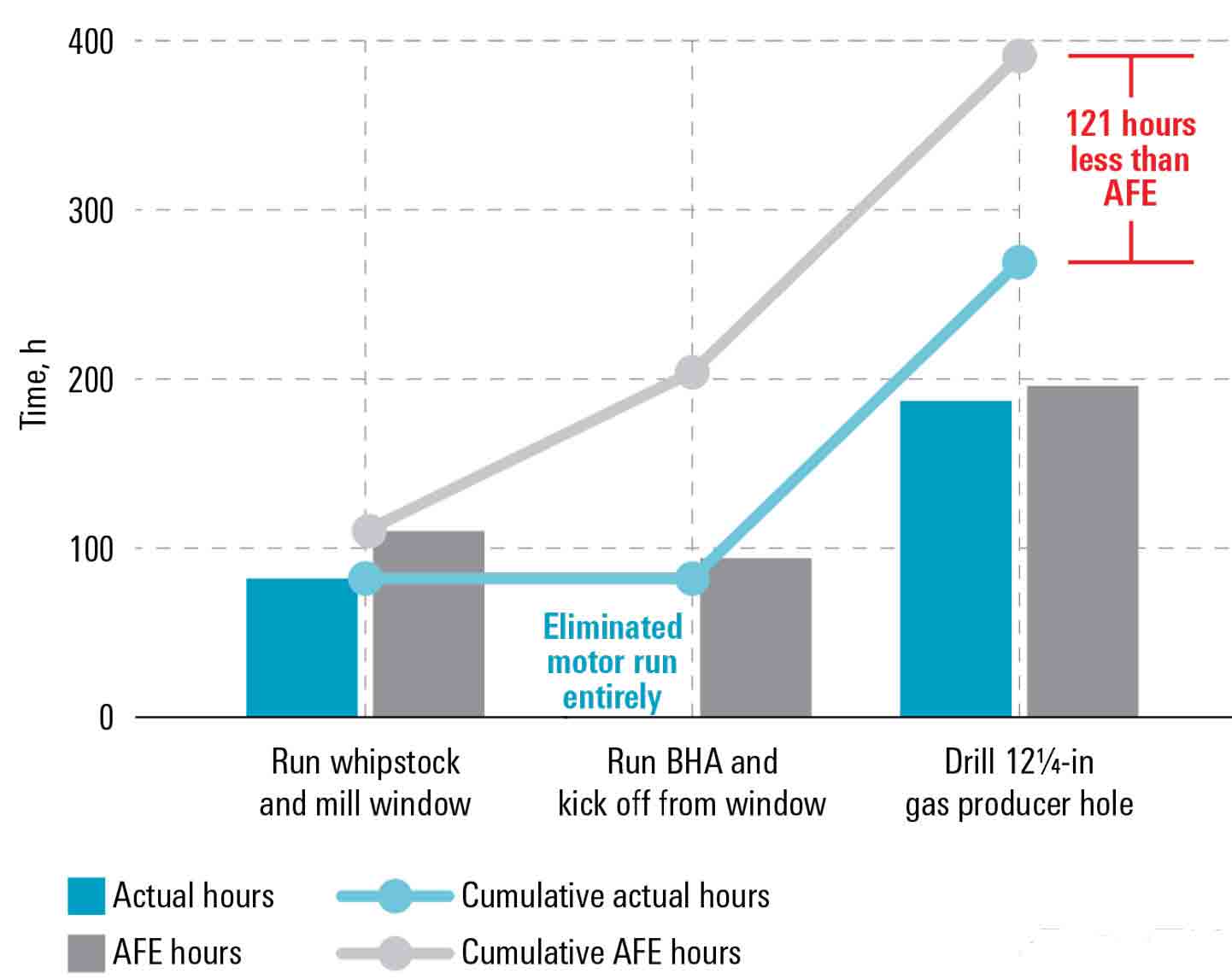

The TrackMaster Select system completed the whipstock milling and rathole extension in a single run. The operator eliminated a planned motor run using PowerDrive Xcel RSS with gyro technology, saving a cumulative 5 days of rig time. Drilling followed the planned trajectory without incident due to the gyro technology. Additionally, the near-bit continuous inclination enabled dogleg severity control at 3.6°/30 m. The customer estimated that application of the combined technology and workflow in future planned operations could result in significant savings.

Challenge:

- Eliminate a motor run required to extend a rathole

- Kick off from an existing well with 81° inclination using an RSS

Solution:

- Use the PowerDrive Xcel RSS with gyro technology coupled with a TrackMaster Select modular whipstock sidetracking system

Results:

- Saved 5 rig days by eliminating a planned motor run

- Completed the whipstock milling and rathole in a single run

- Kicked off using an RSS while in an environment with casing interference

- Minimized hole tortuosity thanks to near-bit inclination measurement