Enable discipline experts to work together and make the best possible decisions from exploration to production.

Integrated Seismic-to-Simulation Workflow Identifies Highest-Productivity Sweet Spots in Major Shale Gas Play

Published: 05/05/2015

Integrated Seismic-to-Simulation Workflow Identifies Highest-Productivity Sweet Spots in Major Shale Gas Play

Published: 05/05/2015

Variation in the shale reservoir and production performance

An operator in a major unconventional shale gas play wanted to better understand the factors controlling reservoir quality and production. The facies vary in matrix quality; presence, orientation, and status of natural fractures; and net gas porosity along the length of the laterals, some of which extend 5,000 ft. Production varies by a factor of three or more between wells. A comprehensive, calibrated workflow was needed to apply these and other factors for ranking potential drill locations, predicting production performance, planning drilling, and designing completions.

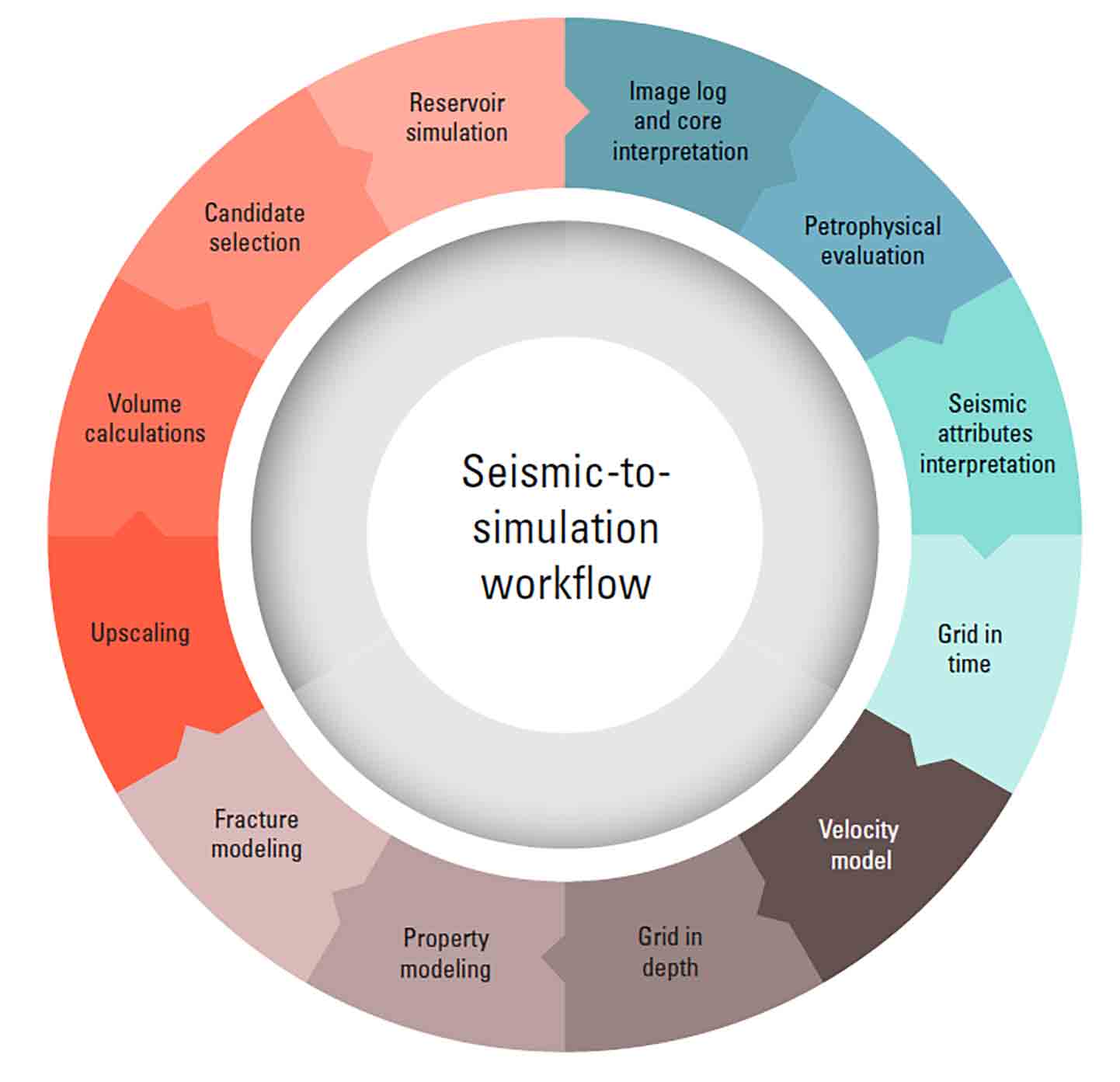

Seismic-to-simulation workflow for unconventional reservoirs

To better understand and predict the performance of gas wells in the shale play, Schlumberger petrotechnical experts incorporated geologic, seismic, and production data in a comprehensive workflow. Using the Petrel E&P software platform for data integration, the experts developed a dual-porosity reservoir model, with image logs calibrated to the core and log data. Surface seismic surveys provided a critical link for propagating the reservoir properties and their variability between the individual wells. Simulations based on the model were history matched with production data.

Identification of the highest-productivity sweet spots

Schlumberger petrotechnical experts collaborated with the operator to employ the seismic-to-simulation workflow with the calibrated 3D reservoir model to not just identify sweet spots but to grade them early in the field development process by their reservoir quality and induced fracture permeability. Variation in these properties and others, such as the stress regime, are used to guide lateral placement and completion design, instead of basing these critical activities on properties interpolated from logged vertical wells that can be a considerable distance from the hydraulic fracture stimulation.

Challenge: Maximize performance in a major gas shale play with widely variable reservoir quality.

Solution: Collaborate with Schlumberger petrotechnical experts to employ a comprehensive seismic-to-simulation workflow for constructing and calibrating a 3D dual-porosity reservoir model that integrates core, log, seismic, and production data to identify the key production drivers of matrix quality, natural fractures, and net gas porosity as those properties vary across the reservoir.

Results: Reliably identified the highest-productivity sweet spots and designed effective completions that account for local reservoir and geomechanical properties along the planned laterals on the basis of a better understanding of how production is controlled by those properties.