Improve acid stimulation efficiency in carbonate reservoirs with high permeability contrast and fluid loss challenges.

Matrix Treatment for Efficient Stimulation in Qatar’s North Field

Published: 01/01/2010

Matrix Treatment for Efficient Stimulation in Qatar’s North Field

Published: 01/01/2010

Stimulating Qatar’s North field

The Khuff carbonate formation is the main reservoir in Qatar’s North field, which is the largest gas field in the world. Wells drilled in this thick, heterogenic reservoir are susceptible to large variations in transmissibility. In addition, permeability contrasts between zones are common—up to a factor of 100—and the hydrostatic column of stimulation fluids tends to stimulate the bottom zones at the expense of the upper reservoir layers in the long gas wells that are typical of the North field. Effectively and uniformly stimulating all zones in one treatment without using conventional mechanical diversion techniques (e.g., packers, sliding sleeves, ball sealers, etc.) has been extremely challenging. In addition, the operational risks are higher because multiple interventions are required.

Engineering a fit-for-purpose solution

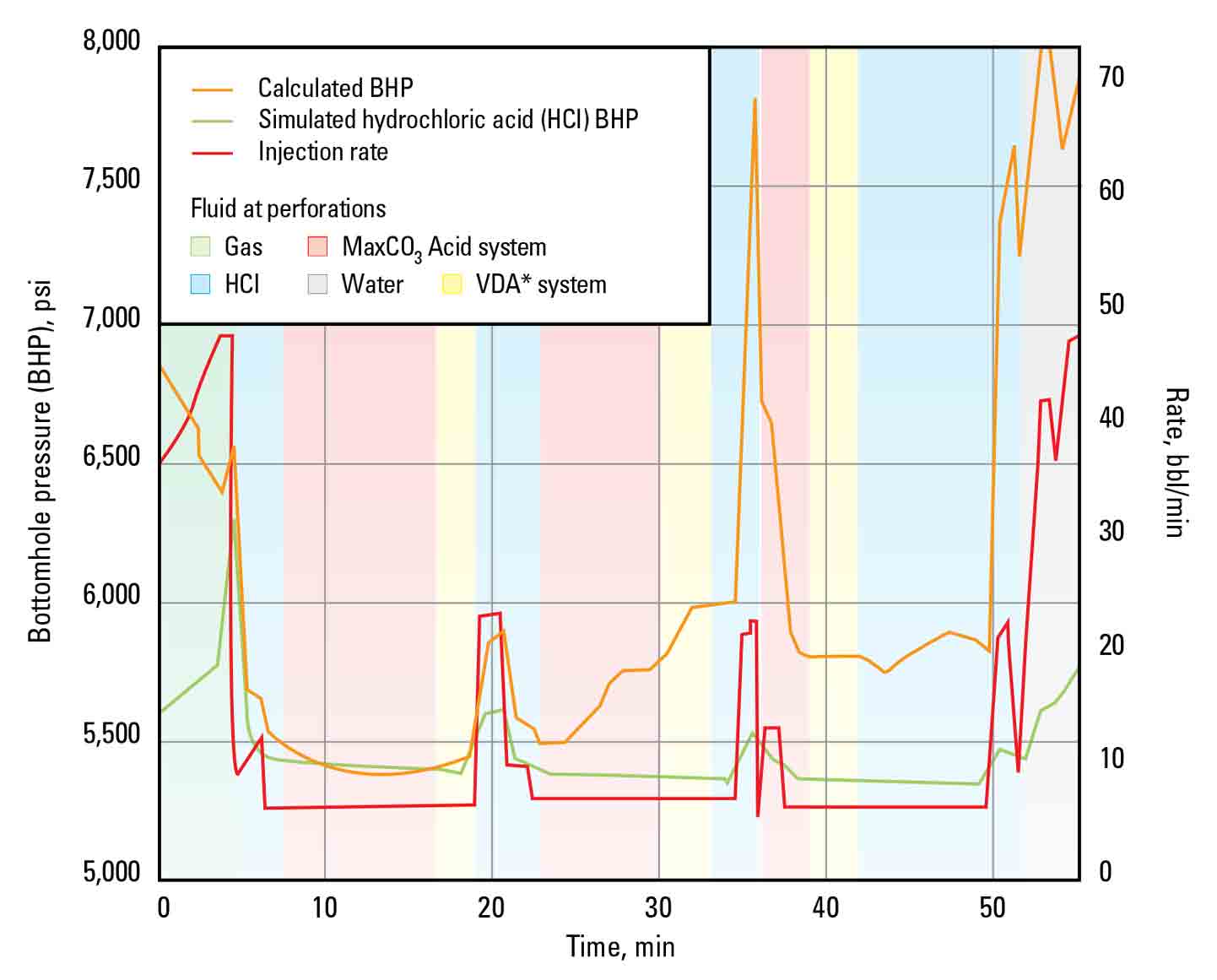

Based on extensive stimulation work in the North field, the Schlumberger Well Book software application for treatment design, execution, and evaluation has a calibrated carbonates stimulation model for regular and viscoelastic acid fluid systems. Additional work was done to include a model for the MaxCO3 Acid degradable diversion system in the existing simulator to

- provide a tool for the prejob planning and postjob evaluation

- better understand the reservoir response

- optimize subsequent treatments

During the initial campaign, 11 treatments were performed in the North field. Post stimulation production logs on three of the wells confirmed the diversion efficiency. Treatment intervals ranged from 195 to 580 ft of perforated casing, distributed over four distinct zones with varying permeabilities, using alternating stages of 28% hydrochloric acid (HCl) and the MaxCO3 Acid system.

Achieving efficient and uniform stimulation results

The actual data, post-treatment pressure, and production log were matched using the Well Book software, which indicated that stimulation of the lower permeability zones was only possible using the MaxCO3 Acid system. Post-treatment production log reflected the same results and showed a more uniform distribution using the MaxCO3 Acid system.

The MaxCO3 Acid system significantly improved the efficiency of the operation. Treatment volumes were reduced by up to 50%, resulting in shorter well cleanup times and less flaring. Because multiple interventions were not needed to perforate and stimulate the zones individually, rig time and operational time were reduced by 30%.

About the Contact family

The MaxCO3 Acid system is part of the dynamic category of the Contact four-category portfolio of staged fracturing and completion services. These technologies maximize reservoir contact by offering the most efficient and effective services for each well. The Contact dynamic category offers fluid-base and tool-free fracturing of multiple stages in one continuous operation. Contact services can be enhanced with real-time measurement options.

Challenge: Effectively and uniformly stimulate zones in a thick carbonate reservoir characterized by large permeability contrasts.

Solution: Use MaxCO3 Acid degradable diversion acid system to achieve superior diversion and uniform stimulation of zones.

Results: Achieved uniform stimulation of zones while reducing rig and operational times by 30% and reducing treatment volumes by 50%, which shortened cleanup time and reduced flaring.