Vx Technology Delivers Flow Rate Measurement Solution for Extraheavy Oil

Published: 02/10/2010

Vx Technology Delivers Flow Rate Measurement Solution for Extraheavy Oil

Published: 02/10/2010

Flow rate and GVF measurements needed in an extraheavy oil reservoir

Recently, Petróleos de Venezuela S.A. (PDVSA) began producing extraheavy oil (8.6 to 10.6 API) from a cluster of wells in the northern section of the Monagas state, the largest producing area in Venezuela. The producing wells in the Orocual field flow various fluids, from gas condensates, light and medium oils, to extraheavy oil. Cold production methods, without diluents, are used in the field, and extraheavy oil is lifted by progressive cavity pumps.

Because this is a new development, no previous data were available, and PDVSA was forced to use conventional storage tanks to measure liquid flow rates. To better understand the behavior of the reservoir and optimize well performance, it was essential that PDVSA have access to total flow rate and GVF data.

Vx technology provides breakthrough solution

Vx technology has been engineered to operate in high-viscosity environments such as extraheavy oil. Because Vx technology is based on a nuclear mass attenuation principle, it distinguishes fluids by their compositions rather than their densities. Therefore, it can differentiate water, oil, and gas by measuring the phase holdups.

Further, Vx technology uses a specific-fraction, high-frequency measurement technique to enable accurate multiphase flow measurements, even in the presence of emulsions or foams that are typical in extraheavy oil and viscous environments. Vx technology can be deployed using PhaseTester equipment or PhaseWatcher* fixed multiphase well production monitoring equipment.

An entire flow measurement solution with one technology

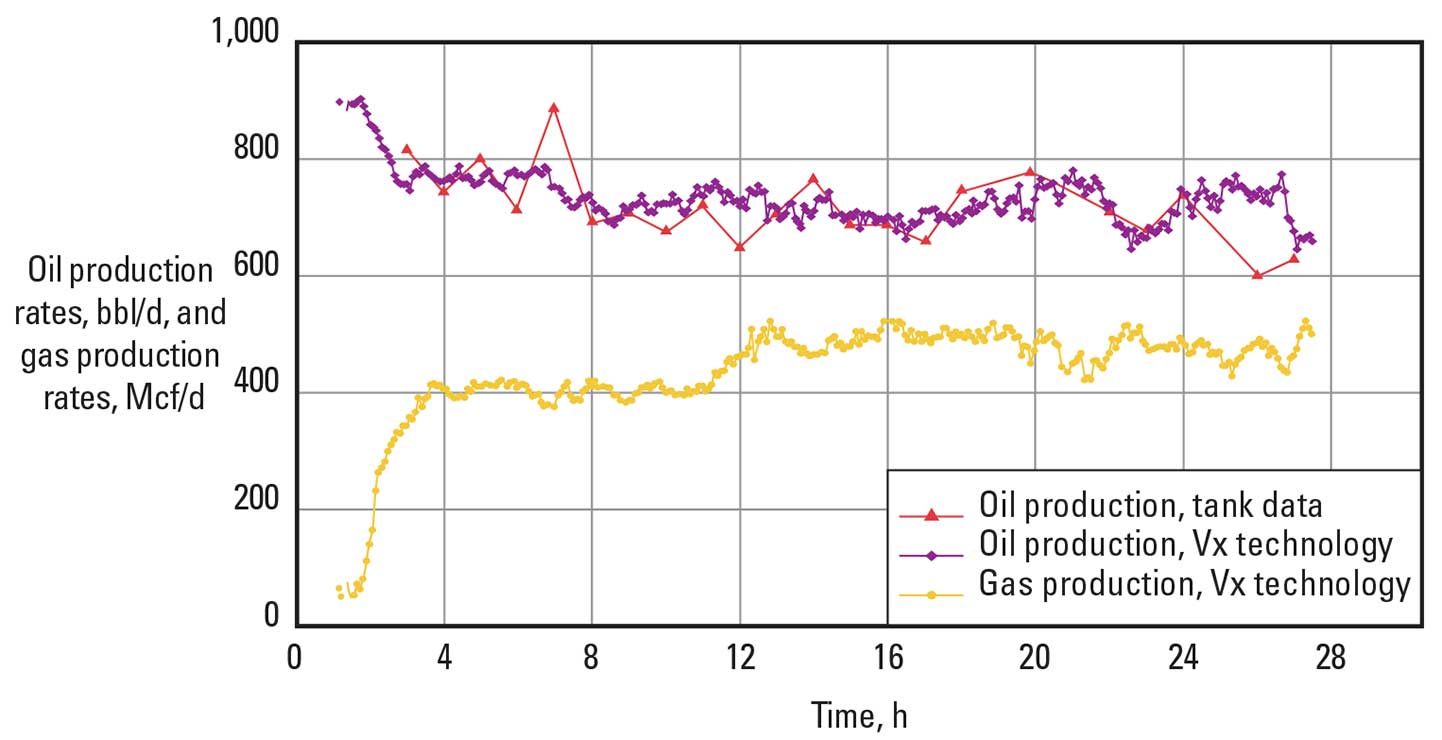

Schlumberger broke the extraheavy oil paradigm related to multiphase technology by using its PhaseTester equipment with Vx technology to measure flow rates from a cluster of PDVSA wells. The latest Vx oil mode software, which is dedicated to viscous oils, was used during the comparative tests in which the viscosity of liquids at line conditions reached more than 6.3 Pa.s.

The relative error in liquid flow rate measurements, taking into account the shrinkage factor and other properties, indicated less than a 2% overall uncertainty comparing storage tank and PhaseTester equipment. Of greater importance though is that PDVSA, for the first time, was able to acquire gas flow rate and GOR data.

With the introduction of Vx technology in the Orocual field, Schlumberger demonstrated that it is the only company capable of providing an entire flow rate measurement solution with one technology. It not only broke the heavy oil paradigm related to multiphase measurement technology, but also extended the operating envelope for PDVSA from gas to extraheavy oil and provided a solution where competitors could not.

Challenge: Obtain reliable liquid flow rate and gas/ volume fraction (GVF) to better understand reservoir behavior in an extraheavy oil field and to optimize production

Solution: Use the PhaseTester portable multiphase well testing equipment with Vx multiphase well testing technology to measure liquid and gas flow rates

Result: Delivered highly accurate gas and GOR data to the client for the first time