The Defining Series: Well Cementing Fundamentals

Published: 01/01/2012

The Defining Series: Well Cementing Fundamentals

Published: 01/01/2012

Well cementing consists of two principal operations—primary cementing and remedial cementing. Primary cementing is the process of placing a cement sheath in the annulus between the casing and the formation. Remedial cementing occurs after primary cementing, when engineers inject cements into strategic well locations for various purposes, including well repair and well abandonment.

Primary cementing is a critical procedure in the well construction process. The cement sheath provides a hydraulic seal that establishes zonal isolation, preventing fluid communication between producing zones in the borehole and blocking the escape of fluids to the surface. The cement sheath also anchors and supports the casing string and protects the steel casing against corrosion by formation fluids. Failure to achieve these objectives may severely limit the well's ability to reach its full producing potential.

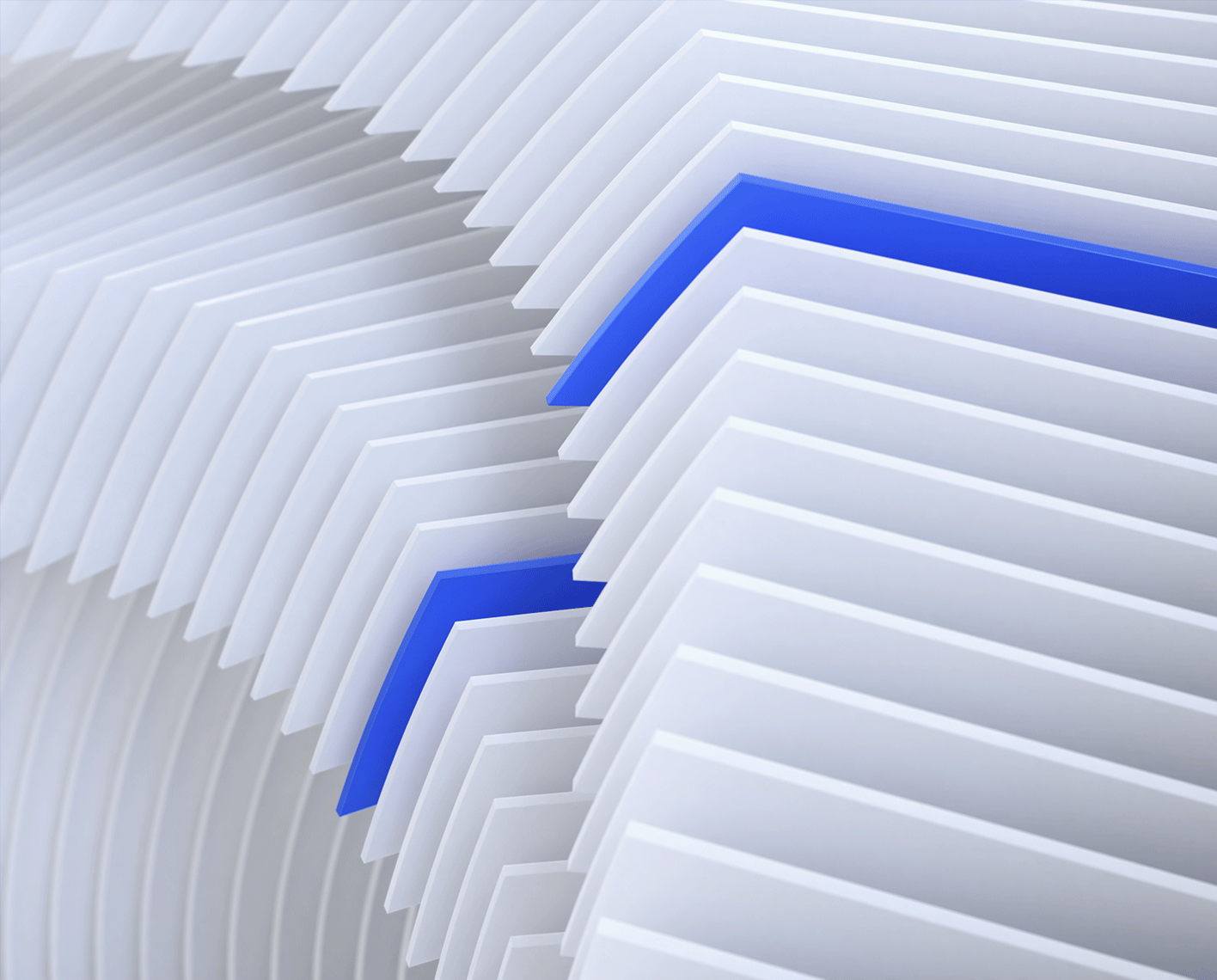

Most primary cementing operations employ a two-plug cement placement method (right). After drilling through an interval to a desired depth, a drilling crew removes the drillpipe, leaving the borehole filled with drilling fluid. The crew then lowers a casing string to the bottom of the borehole. The bottom end of the casing string is protected by a guide shoe or float shoe. Both shoes are tapered, commonly bullet-nosed devices that guide the casing toward the center of the hole to minimize contact with rough edges or washouts during installation. The guide shoe differs from the float shoe in that the former lacks a check valve. The check valve can prevent reverse flow, or U-tubing, of fluids from the annulus into the casing. Centralizers are placed along critical casing sections to help prevent the casing from sticking while it is lowered into the well. In addition, centralizers keep the casing in the center of the borehole to help ensure placement of a uniform cement sheath in the annulus between the casing and the borehole wall.

As the casing is lowered into the well, the casing interior may fill with drilling fluid. The objectives of the primary cementing operation are to remove drilling fluid from the casing interior and borehole, place a cement slurry in the annulus and fill the casing interior with a displacement fluid such as drilling fluid, brine or water.

Cement slurries and drilling fluids are usually chemically incompatible. Commingling them may result in a thickened or gelled mass at the interface that would be difficult to remove from the wellbore, possibly preventing placement of a uniform cement sheath throughout the annulus. Therefore, engineers employ chemical and physical means to maintain fluid separation. Chemical washes and spacer fluids may be pumped after the drilling fluid and before the cement slurry. These fluids have the added benefit of cleaning the casing and formation surfaces, which helps achieve good cement bonding.

Wiper plugs are elastomeric devices that provide a physical barrier between fluids pumped inside the casing. A bottom plug separates the cement slurry from the drilling fluid, and a top plug separates the cement slurry from the displacement fluid. The bottom plug has a membrane that ruptures when it lands at the bottom of the casing string, creating a pathway through which the cement slurry may flow into the annulus. The top plug does not have a membrane; therefore, when it lands on top of the bottom plug, hydraulic communication is severed between the casing interior and the annulus. After the cementing operation, engineers wait for the cement to cure, set and develop strength - known as waiting on cement (WOC). After the WOC period, usually less than 24 hours, additional drilling, perforating or other operations may commence.

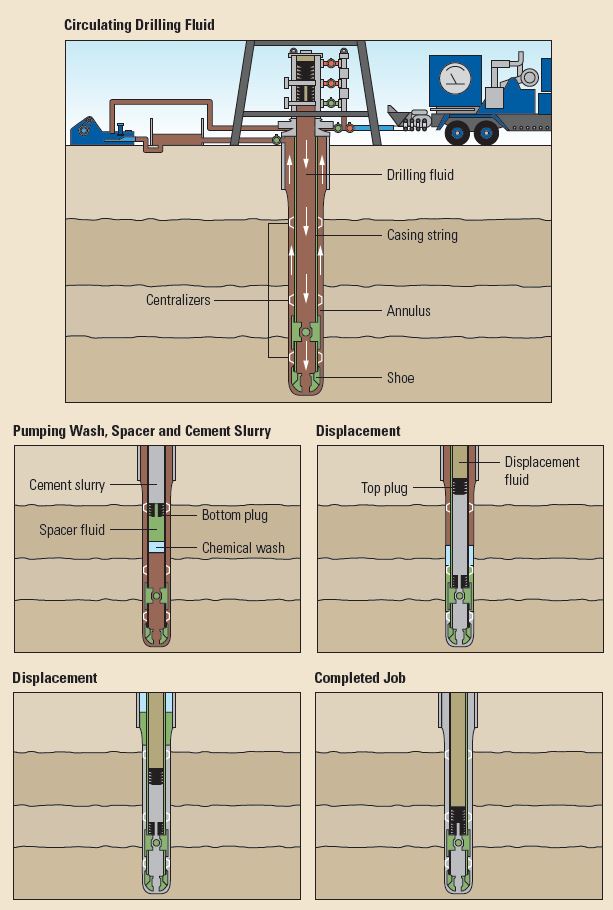

Well construction typically consists of installing several casing strings, each requiring a primary cementing operation (Figure 2). As the well deepens, the diameter of each casing string is usually smaller than the preceding one.Nearly all well cementing operations use portland cement, which consists mainly of anhydrous calcium silicate and calcium aluminate compounds that hydrate when added to water. The hydration products, principally calcium silicate hydrates, provide the strength and low permeability required to achieve zonal isolation.

The conditions to which portland cements are exposed in a well differ significantly from those encountered at ambient surface conditions associated with buildings, roads and bridges. Well cements must perform over a wide temperature range - from below freezing in permafrost zones to temperatures exceeding 400 degC [752 degF] in geothermal wells. Consequently, cement manufacturers produce special versions of portland cement for use in wells. In addition, more than 100 cement additives are available to adjust cement performance, allowing engineers to customize a cement formulation for a particular well environment. The principal objective is to formulate a cement that is pumpable for a time sufficient for placement in the annulus, develops strength within a few hours after placement and remains durable throughout the well's lifetime.

Additives may be classified according to the functions they perform. Accelerators reduce the cement setting time and increase the rate of compressive strength development. Retarders delay the setting time and extend the time during which a cement slurry is pumpable. Extenders lower the cement slurry density, reduce the amount of cement per unit volume of set product, or both. Weighting agents increase the density of the cement. Fluid loss control agents control leakage of water from the cement slurry into porous formations, thereby preserving the designed cement slurry properties. Lost circulation control agents limit flow of the entire cement slurry out of the wellbore into weak, cracked or vugular formations and help ensure that the cement slurry is able to fill the entire annular space. Dispersants reduce the viscosity of the cement slurry, which allows a lower pumping pressure during placement. Specialty additives include antifoam agents, fibers and flexible particles. Cement additives are an active domain of research and development, and the industry regularly introduces new and improved products.

After a cementing operation has been performed and the cement has set, engineers frequently perform tests to confirm that the cement sheath integrity and performance meet the intended design criteria. Cement evaluation techniques include hydraulic testing and various well logging methods.

Pressure testing is the most common hydraulic testing method. It is typically conducted after every surface- or intermediate-casing cement job. The driller first performs a casing pressure test to verify the mechanical integrity of the tubular string and then drill out the casing shoe. Next, the driller performs a pressure integrity test by increasing the internal casing pressure until it exceeds the pressure that will be applied during the next drilling phase. If no leakage is detected, the cement seal is deemed successful.

Engineers may choose from several well logging techniques to evaluate the quality of the cement behind casing. The logging crew lowers measuring devices into the well and plots the acquired data versus depth. Temperature logs help locate the top of the cement column in the annulus. Cement hydration is an exothermic process that raises the temperature of the surrounding environment. Data from acoustic and ultrasonic logging tools help engineers analyze the cement/casing and cement/formation interfaces. These tools provide information about the quality of the cement sheath and how well the cement adheres, or bonds, to the casing and to the formation.

The cement bond log presents the reflected amplitude of an acoustic signal transmitted by a logging tool inside the casing. The cement-casing bond integrity is directly proportional to the attenuation of the reflected signal. Another acoustic log presents the waveforms of the reflected signals detected by the logging tool receiver and provides qualitative insights concerning the casing, the cement sheath and the formation. Ultrasonic logging tools transmit a short ultrasonic pulse, causing the casing to resonate. The tool measures the resonant echoes; when solid cement is behind the casing, the echo amplitudes are attenuated. When there is fluid behind the casing, the echoes have high amplitudes.

When logging operations indicate that the cement job is defective, either in the form of poor cement bonding or communication between zones, a remedial cementing technique known as squeeze cementing may be performed to establish zonal isolation. A cementing crew perforates the casing at the defective interval and forces, or squeezes, cement slurry through the perforations and into the annulus to fill the voids. In addition, squeeze cementing may be an effective technique for repairing casing leaks caused by a corroded or split casing.

When a well has reached the end of its productive life, operators usually abandon the well by performing plug cementing. Engineers fill the casing interior with cement at various depths, thereby preventing interzonal communication and fluid migration into underground freshwater sources. The ultimate objective is to restore the natural integrity of the formations that were disrupted by drilling.

Well cementing technology is more than 100 years old; however, chemists and engineers continue to introduce new formulations, materials and technology to meet the constantly changing needs of the energy industry. For example, the durability of zonal isolation, during and after a well's productive life, is a major research and development topic. Modern cement systems may contain flexible particles and fibers that allow set cement to withstand severe mechanical stresses. Advanced self-healing cement systems contain "smart" materials that, upon cement-sheath failure, swell and reestablish zonal isolation when contacted by either aqueous or hydrocarbon formation fluids. The ultimate goals of these cementing technologies are to withstand the rigors of well operations and other disruptions that may occur over time and maintain zonal isolation indefinitely.

Oilfield Review Summer 2012: 24, no. 2.

Copyright © 2012 Schlumberger.