Grove BT1

Valves

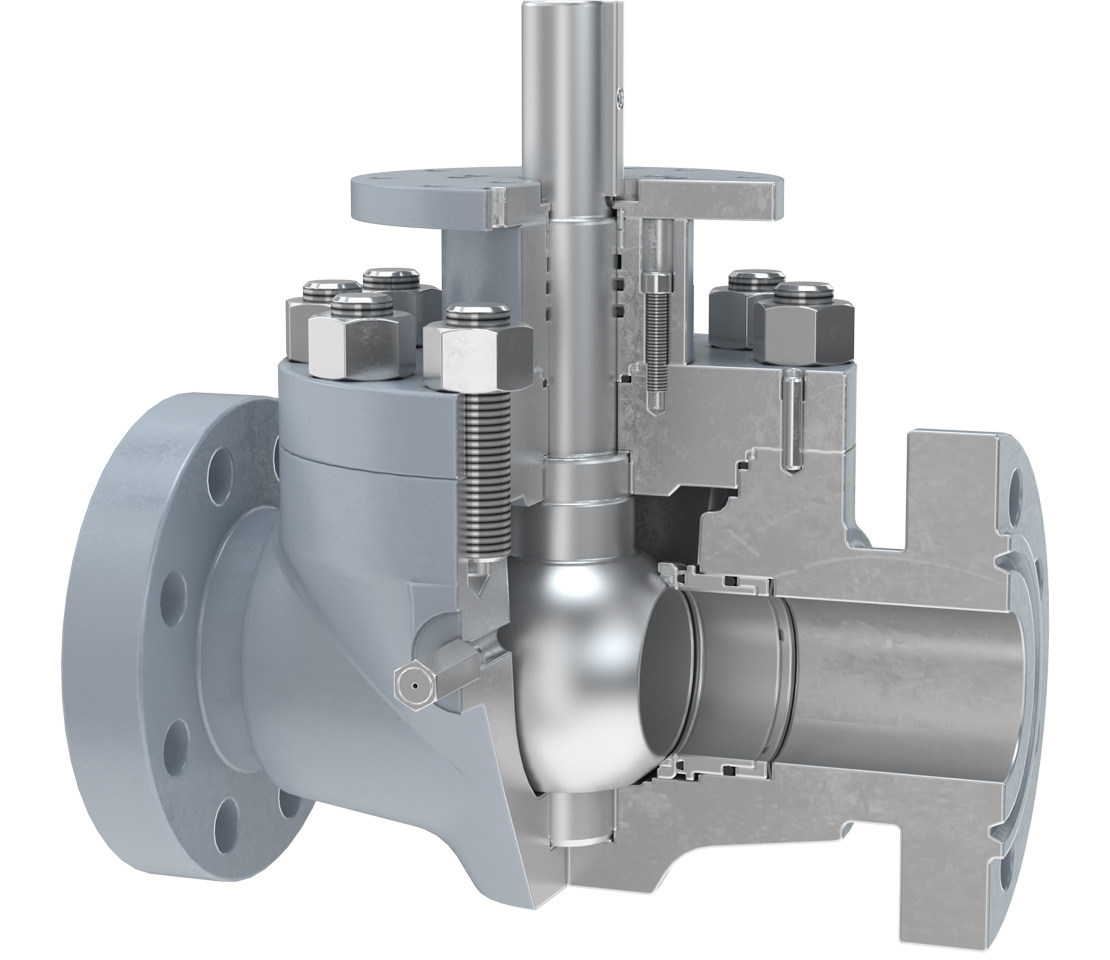

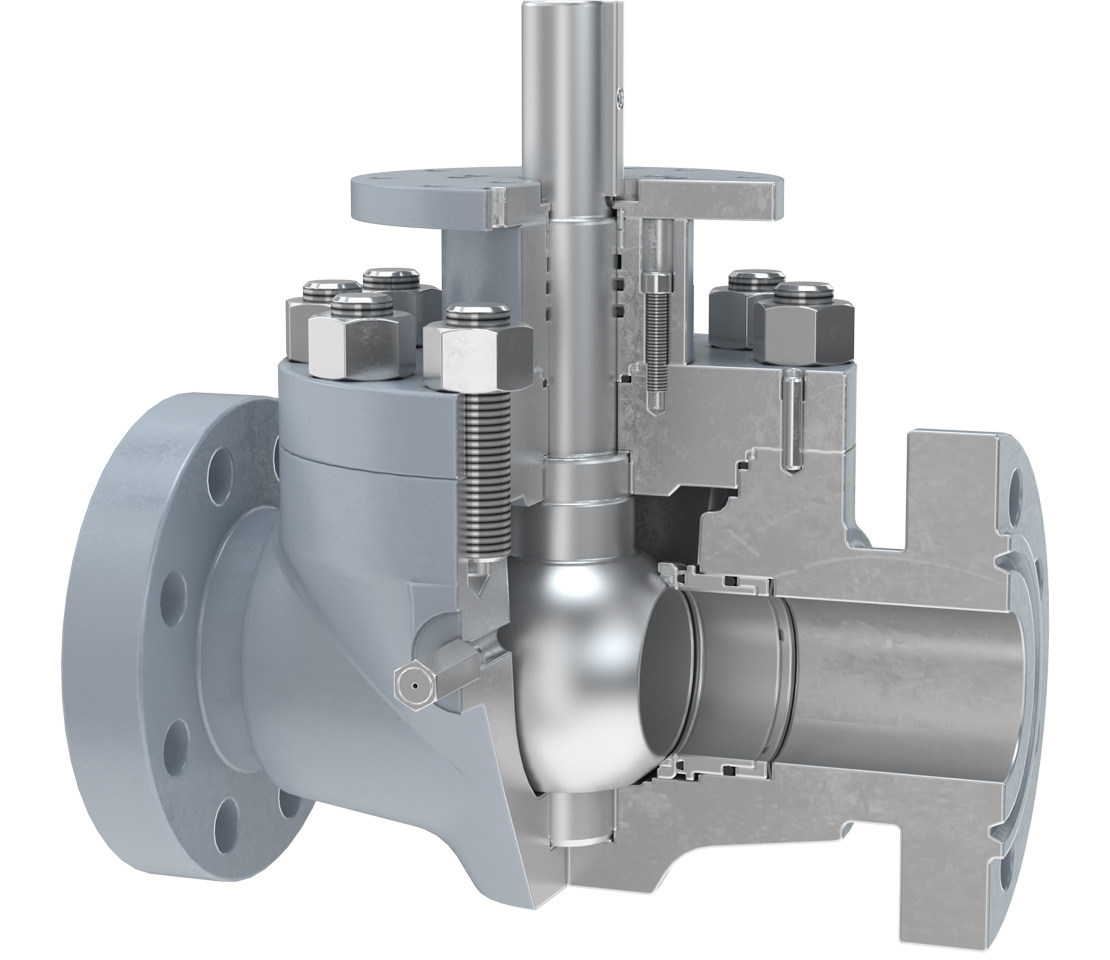

The top-entry Grove BT1 valve is manufactured in a wide range of diameters and pressure classes. In the standard versions, the valve is suitable for transmission pipelines, pumping, compression and reinjection units, offshore platforms, onshore terminals, pig traps, measuring stations, and surge-relief skids. In addition to oil and gas applications, the valve can be used for renewable fuels service. Whenever ball valves are used in critical service applications, in situ field repairability with quick turnaround is often needed.

Size

1/2 to 12 in

Pressure classes

ANSI 150 to 1500

Standard features

- Trunnion-mounted design

- Triple-barrier stem seals

- Antiblowout stem design

- Stem emergency grease fitting

- Factory-positioned external stops for a permanent reference to open and closed positions

- Low-friction, metal-backed, self-lubricating PTFE sleeve bearings and thrust washers

- Plastic polymer insert for seat sealing

- Double-piston effect (DPE) seat rings (double-sealing barrier in both directions)

- Double block-and-bleed capability

- Pressure-relief valve in the body cavity to prevent pressure lock

- Electroless nickel coating on pressure-controlling parts and stem

- Body thickness in accordance with ASME B16.34

- In-line repairable

- CE marking (PED directive)

Options

- Self-relieving seat rings

- Lubricated seats

- PTFE spring-energized lip seals for seat and stem sealing

- Metal-to-metal seat sealing

- Stainless steel or INCONEL 625 overlay on sealing areas

- Explosive decompression-resistant seals (standard for Class 600 and higher)

- Antistatic device

- Features to allow vertical installation and maintenance

Standards compliance

- Fire-safe in accordance with API Specs 6FA and BS 6755 Part 2

Body construction

- Body bonnet design features bolted construction, and its sizing complies with requirements given in ASME VIII Div. 1

- Bolted construction allows in-line disassembly for inspections and potential repairs

- Removing the bonnet from the valve allows free access to the ball and the seats, which can simultaneously be taken out without the need for any special maintenance tools

- After maintenance, seating surface integrity can be assessed by pressurizing the body cavity only, before any repressurization of the pipeline (standard DPE design)

- Body drain provided in the lowest part of the body cavity, featuring an NPT drain valve with a safety plug