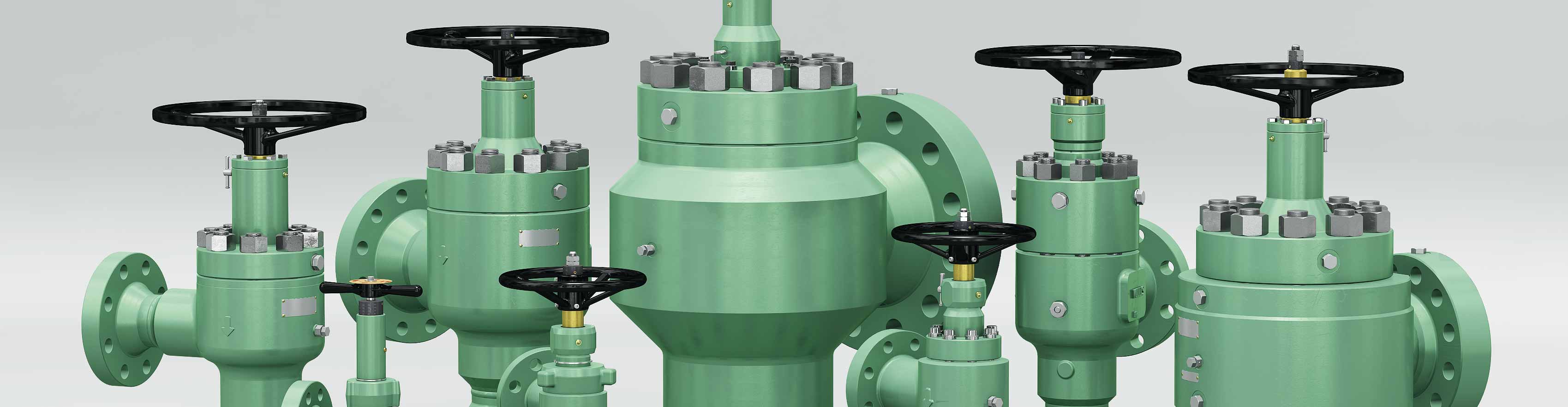

HT Choke

For all heavy oil recovery operations

Dedicated to high-temperature service, Cameron HT-rated chokes are a proven flow control solution for all heavy oil recovery operations, including steam-assisted gravity drainage (SAGD) and cyclic steam stimulation (CSS).

The industry standard in flow control technology, control chokes have been a crucial element of wellhead and production equipment for more than 30 years. The plug & cage trim design ensures consistent performance—whether it’s injection or production, SAGD, or CSS. Our HT chokes provide durability, impact protection, erosion resistance, and accurate controllability with multiple trim capacities and flow characteristics for each nominal choke valve size.

Features

- Full product range from 2-in to 6-in nominal sizes

- Modular top end design available in manual or actuated configurations

- Actuation components are strategically distanced from the heat of the bore fluids, effectively isolating the operator from the thermal energy

- Forged body construction available in flanged, studded, or clamp hub end connections, with further options to suit specific requirements

- High-density graphite filament stem packing stack with multiple redundancy and easy installation and adjustment, thus providing trouble-free sealing in conditions up to 650 degF

- Tungsten carbide trim components as standard, offering erosion resistance and extended service life in the most severe service wells

- Stainless steel and Stellite trims available

- Optional wear sleeve for enhanced protection of the choke body

Specifications

- Up to 10,000-psi pressure rating as standard

- Extended HPHT ratings also available

- Full range of flanges, end connections, and interface dimensions available

- API Spec 6A material classes EE, FF, and HH

- API Spec 6A temperature classifications over range L–Y (–50 to 650 degF [–46 to 345 degC]

- All types of service: Bitumen, steam, water, gas, sour, and sandy service

- Canadian Registration Number approval

Actuation options

- Manual handwheel

- Linear pneumatic: diaphragm or piston type

- Linear hydraulic actuation

- Stepping actuation: hydraulic or pneumatic

- Electric actuation

Trim options

- Linear and equal percentage trim characteristics

- Reduced capacity trim for low Cv control

- Special trims, including low noise and maximum capacity cages

Maintenance and spares

- Specific trim kits and seal kits for ease of ordering replacement parts

- Easily maintained in the field

- No special tools required