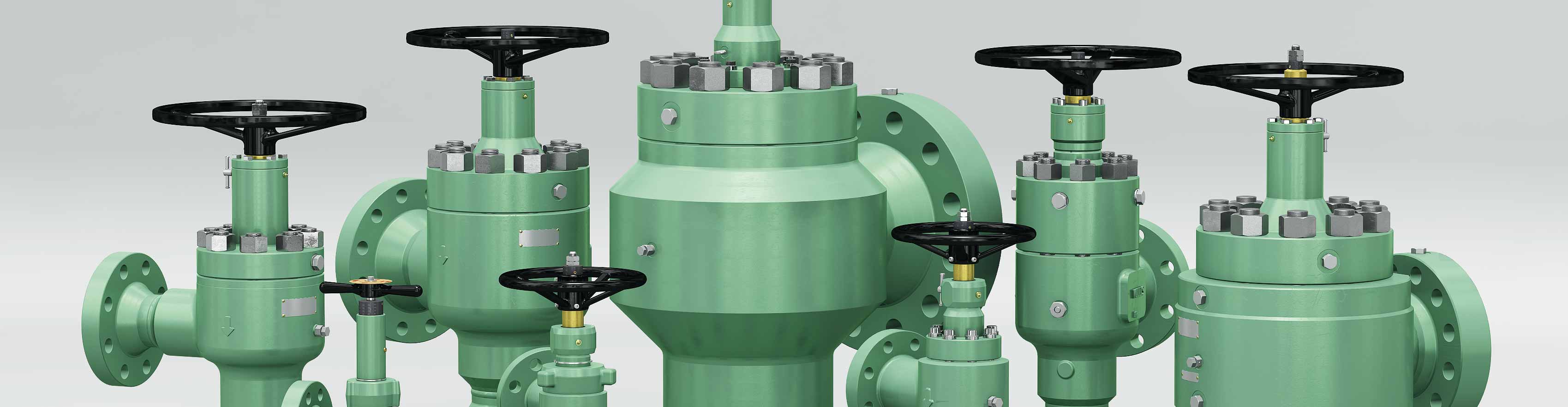

MS33

Multistage control choke

Cameron's MS33 multistage choke trim is used in applications where high differential pressures result in unacceptably high noise and vibration levels, especially in gas service. Multistage trims also are commonly used to prevent cavitation in the case of liquids, particularly for water injection.

The trim works by reducing the pressure over a number of discrete stages, giving a carefully managed pressure profile. Similarly, it manages the velocities within the trim and prevents the occurrence of undesired flow effects such as sonic velocities and high-velocity jetting. In addition to the concentric cage type of trim, Cameron can provide a number of alternative multistage trim options.

Features

- Metal body-to-bonnet gasket for absolute pressure containment

- Heavy-duty thrust bearings reduce operating torque

- Fully guided plug reduces side loading and vibration

- Outer flow cage provides protection from impact damage

Specifications

- Porting and geometry that convert potential energy (i.e., pressure) into kinetic energy and heat as a result of viscous energy dissipation

- Splitting of flow into small streams, reducing the energy levels in each stream

- Large trim surface area that increases wall friction to slow fluid

- Directional changes in trim for reduced energy levels

- Interstage chambers that allow fluid expansion to reduce velocities

- Fluid passage through repeated compression and expansion phases to further reduce energy levels without high velocities

- Pressure-balanced stem and thrust bearings that reduce torque, thus minimizing stem loads, actuator requirements, and handwheel torque

- Large annulus area that reduces the risk of body and trim erosion caused by high velocities