Spur & miter gears

Part of our family of Dynatorque™ valve accessories

Spur and miter gears are used in applications requiring a nonself-locking mechanical advantage or a change in input drive orientation.

Both devices can be used as add-on features to our worm and bevel gears or purchased as stand-alone products.

Spur gears

- Used with worm gear and bevel gear operators for reduced handwheel rim pull effort

- Can be used independent of worm and bevel gears with small nonrising stem gate valves and other nonself-locking applications that require torque multiplication; provide a low-ratio torque multiplier when used with small electric motor operators

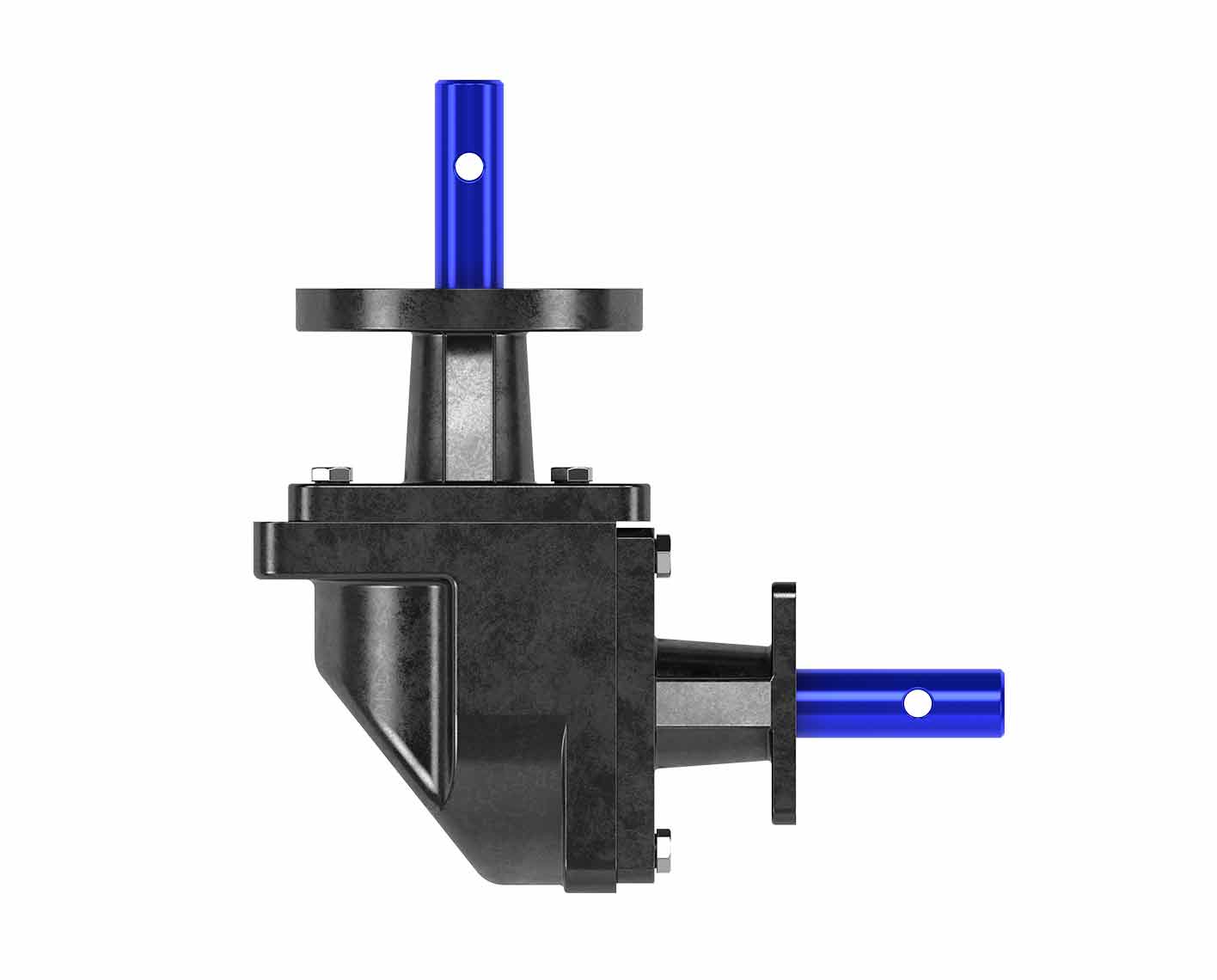

Miter gears

- For use as a close-coupled gearbox that changes handwheel input shaft direction on worm and bevel gears

- Can be used to change shaft direction by 90° on any rotating device with compatible torque values and interface dimensions

Spur gears

- Straight teeth

- Transmission of motion through parallel shafts

- One tooth always in contact and carries the entire transmission load

Miter gears

- Simpler design and fewer components, resulting in ease of use and maintenance compared with more complex gear systems

- Lower cost, making them an economical choice for certain applications, especially low-speed, low-load scenarios

Spur gears

- Heavy-duty iron and steel components

Miter gears

- Heavy-duty iron and steel components

Spur gears

Model

Unit Weight, lbm

Max. Output Torque, lbf.in

Gear Ratio

Turns for 90°

Std. Output Shaft Diameter, in

Std. Mounting Pattern

(Qty. and Size, in)Std. Mounting Pattern

(Bolt Circle), inMechanical Advantage

4:1

34

10,000

4:1

4

Not applicable

(4).406

1.250 × 2.250**

3.2

4:1A*

36

10,000

4:1

4

1.000

(4)1/2-13

2.00 × 2.750

3.2

6:1

37

12,000

6:1

6

Not applicable

(4).406

1.250 × 2.250**

4.8

6:1A*

39

12,000

6:1

6

Not applicable

(4).406

1.250 × 2.250**

4.8

Miter gears

| Model | Unit Weight, lbm | Max. Output Torque, lbf.in | Gear Ratio | Turns for 90° | Std. Output Shaft Diameter, in | Std. Mounting Pattern (Qty. and Size, in) |

Std. Mounting Pattern (Bolt Circle), in |

Mechanical Advantage |

| MT1 | 25 | 3,000 | 1:1 | 1 | Not applicable | (4).406 | 1.250 × 2.250** | 0.9 |

| MT1A* | 26 | 3,000 | 1:1 | 1 | 1.000 | (4).406 | 1.250 × 2.250** | 0.9 |

Table footnotes

* Model numbers that end in A are stand-alone models that are not made to close couple to existing products. These models also have input (handwheel) shaft and output shaft connections. Models that do not end in "A" are designed to close couple to Dynatorque 90™ quarter-turn worm gear operators. These models have input (handwheel) shaft connections and use the input shaft from the primary operator for their output shaft connections. Models that do not end in "A" are offered as component parts that are assembled to primary operators.

** Bolt patterns are offset to match standard spur and miter attachment patterns on faced operators.