Improve production with fewer materials and less carbon intensity for greater efficiency and safer operations.

Hiway Flex customizable flow-channel fracturing technology

Published: 08/14/2025

Hiway Flex customizable flow-channel fracturing technology

Published: 08/14/2025

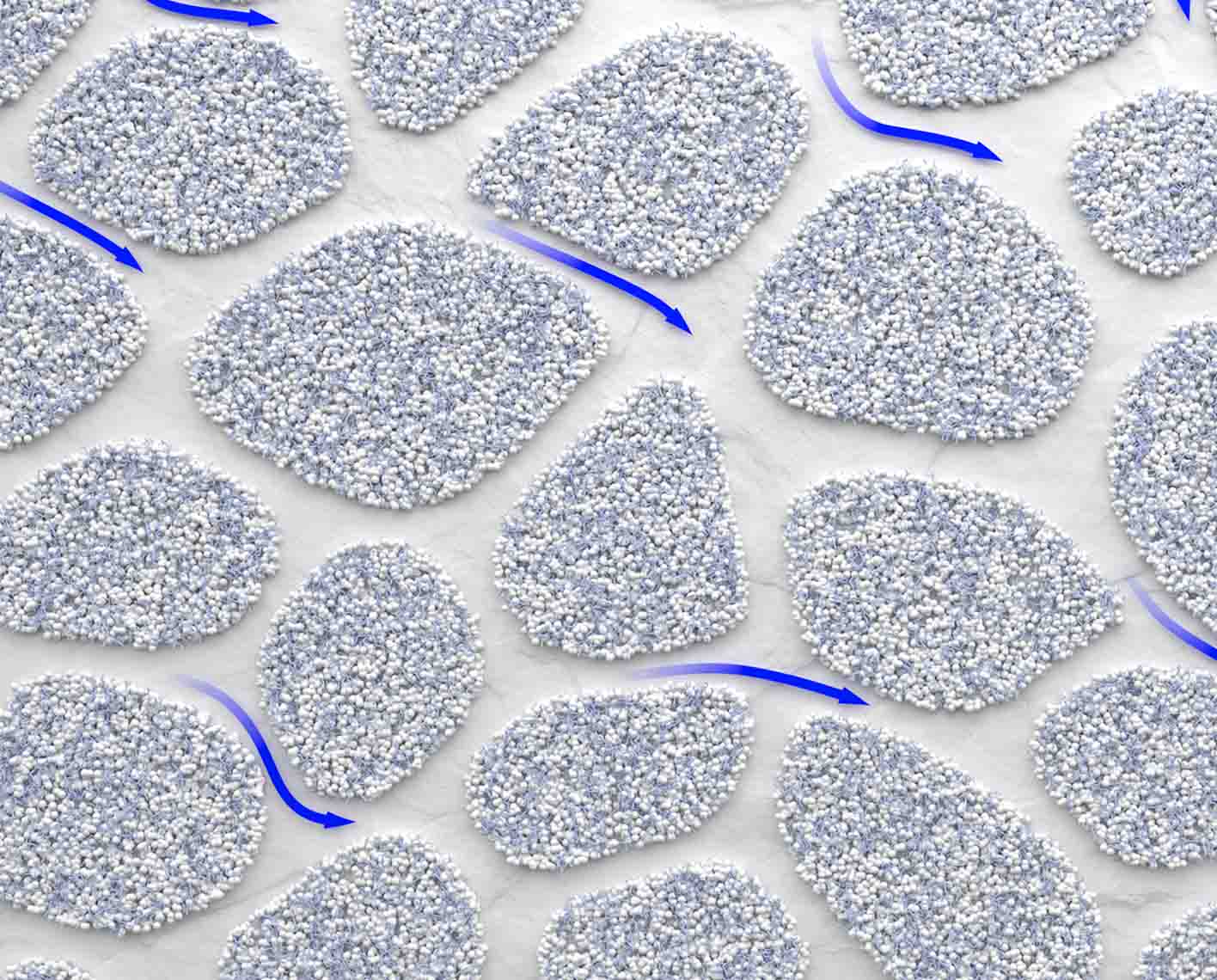

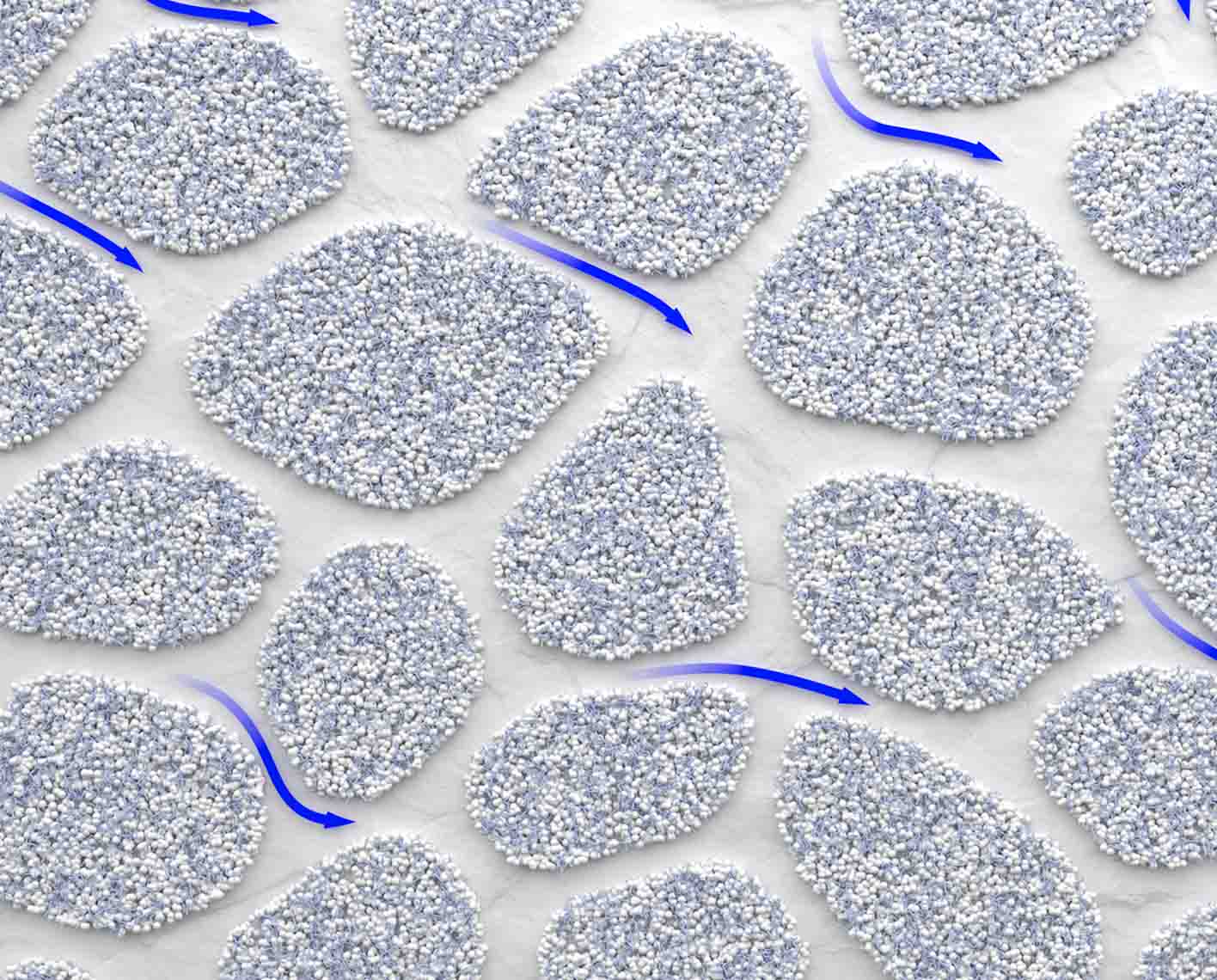

Evolving for greater optimization and sustainability, Hiway Flex™ customizable flow-channel fracturing technology redefines well stimulation by creating open pathways inside the fracture—using up to 40% less proppant.

This reduction in proppant lowers costs, simplifies logistics, and decreases carbon intensity by up to 25%. Unlike conventional fracs, where proppant is continuously pumped, Hiway Flex technology uses a customizable proppant-pulsing design, engineered to match your reservoir’s unique characteristics.

By forming open pathways within the proppant pack, Hiway Flex technology enhances conductivity and extends effective frac length—maximizing connectivity between your reservoir and wellbore for greater hydrocarbon recovery.

To further optimize results, we've developed a powerful digital advisor—driven by a multiphysics model—that tracks pillar movement based on fluid viscosity, pump rates, leakoff, and nearly every factor influencing the frac.

This advanced tool fine-tunes treatment design and material selection, ensuring engineering solutions precisely optimized for your operation’s unique challenges.

Hiway Flex technology is fully customizable and can be integrated with a range of technologies to address reservoir conditions—from proppant flowback control with proprietary fibers to fracture geometry management using far-field diversion pills.

And with successful placement, the risk of screenout is reduced—even in the most challenging well conditions.

Transform your reservoir potential with the advanced capabilities of Hiway Flex technology.