Streamline zipper frac operations and eliminate cut wireline by automating frac valves.

ValveCommander Platform: Overview | Video

Published: 02/11/2021

ValveCommander Platform: Overview | Video

Published: 02/11/2021

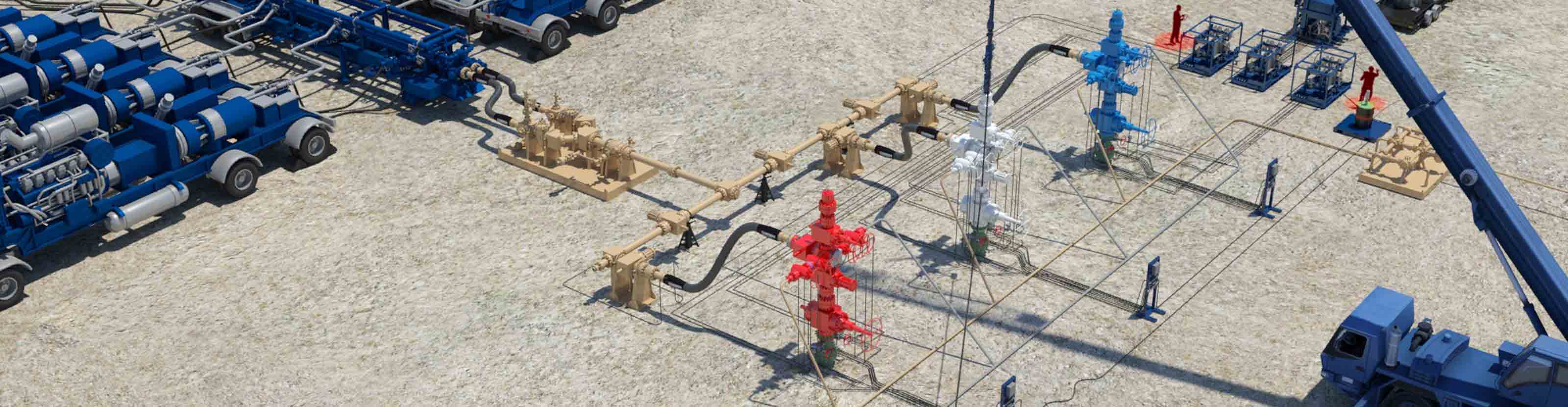

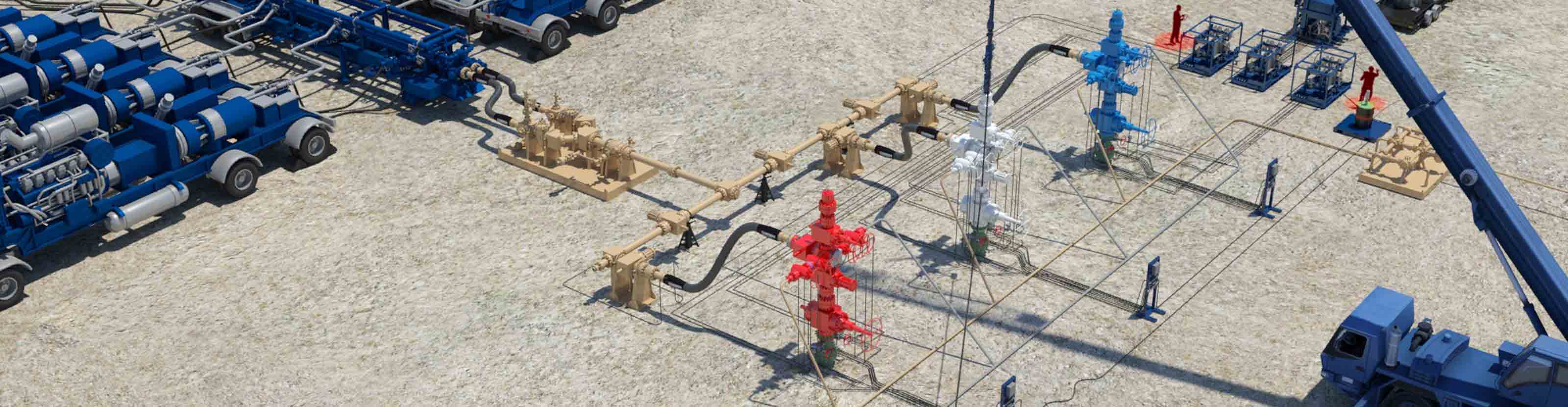

In hydraulic fracturing operations the fracturing fluid is delivered from the missile trailer through the zipper manifold to the frac tree and into the well. In complex multiwell fracturing, wireline and fracturing crews constantly alternate operations among the wells to isolate a well and rig up wireline, or to open a well and pump fracturing fluid to stimulate the formation. Opening and closing valves on the frac tree and manifold must be carried out accurately and in sequence. Conventionally, this requires manual operation of a lever on the hydraulic power unit. This manual-intensive activity creates an operational risk due to the potential for human error. Functioning the wrong valve at the wrong time can cause nonproductive time, add costs, damage equipment, and increase other safety risks.

Cameron ValveCommander automated control and advisory platform enables the industry’s first remotely operated frac tree. Operators can instantly control frac valves with the click of a button and monitor the position of the valves in real time. Visual cues indicate which valves are open and which are closed. The software digitizes the standard workflow of the fluid delivery system, and the advisor offers step-by-step guidance of valve sequence, reducing risk of improper valve operation. On the touch screen, the operator selects the valve to operate. A signal is sent to the digitally enabled skid, which then diverts fluid from the hydraulic power unit to the chosen valve to open or close it. Cameron ValveCommander platform improves efficiency and performance by enabling operators to verify valve position in real time, mitigate overpressuring valves, eEliminate cut wireline, remove workers from the high-pressure zone, digitize a standard workflow to prevent incorrect sequencing, and increase stages per day by more than 10%.