H2S removal from biogas

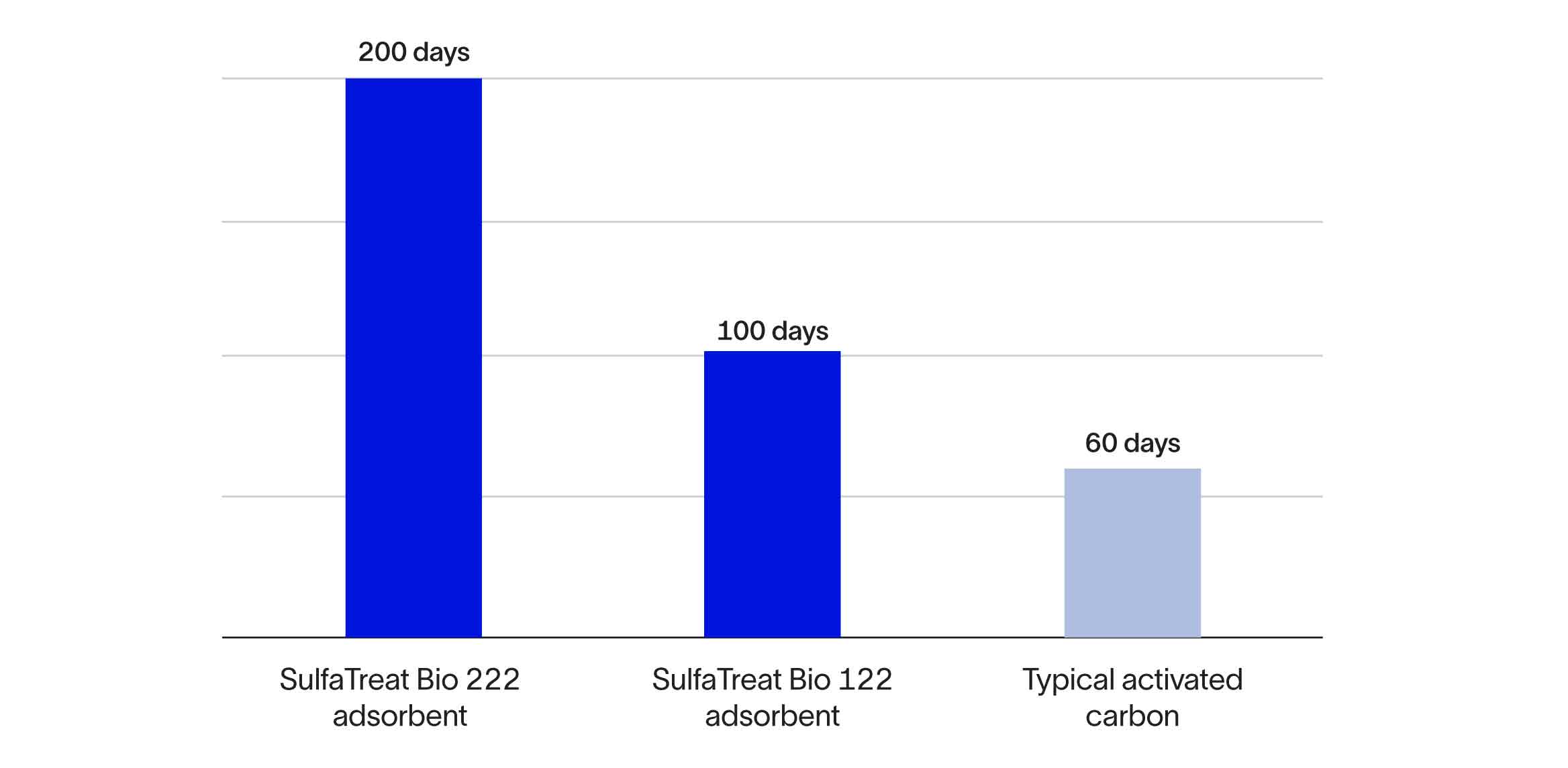

SulfaTreat Bio adsorbents have higher H2S removal capacity than activated carbon

Cost-effective and easy-to-operate solutions

Granular iron-oxide-based SulfaTreat Bio™ biogas hydrogen sulfide removal adsorbents are used in fixed-bed processes and require minimal operator attention.

Highly effective means of H2S removal for biogas, landfill gas, and odor control applications

SulfaTreat Bio adsorbent vs. carbon

Hundreds of biogas and odor control applications worldwide use the SulfaTreat Bio adsorbent. The proprietary iron oxide chemistry is robust and provides numerous benefits, making it a cost-efficient alternative to activated carbon.

| SulfaTreat Bio Adsorbent | Carbon | |

|---|---|---|

| Overview |

Highly selective in removal of H2S. Adsorbent selected based on conditions and parameters specified by customer. Systems designed using proprietary software modeling. |

Universal absorbent, used for removing many contaminants from gas or vapor streams. Removes volatile organic compounds (VOCs), heavy metals, and other components, which lead to disposal issues and also impact capacity. System designs typically based on rules of thumb. |

| Economics |

Consistent performance and predictable unit cost of removal. Product consumption directly related to H2S loading (lbm/d). High density, maximizing removal capacity per cubic foot. |

Unpredictable operating costs where feedstock is variable. Product consumption related to quantity of all species absorbed by the bed. Low density, minimizing media's removal capacity per cubic foot. |

| Environmental |

Nonpyrophoric in both the initial and ready-for-disposal forms. Commonly disposed at a nonhazardous landfill. |

Unpredictable hazard classification of spent media. Commonly disposed via incineration. Potential fire hazard from heat of absorption.*,† |

| Process |

H2S removal by chemical reaction. Functions optimally in high-humidity gas. Works effectively both with and without oxygen. |

Requires high linear gas velocity to enable absorption to take place. Negatively impacted by high humidity. Typically requires oxygen. |

| Monitoring |

Highly predictable bed life, based on gas flow rate and inlet H2S. |

Unpredictable bed life, depending on variable contaminants in treated gas. |

| Performance warranty |

Comprehensive warranty from single-source manufacturer and supplier. |

Typically no warranty provided. Typically sold via third parties as a commodity chemical. |

* United States Environmental Protection Agency, 1997

† UK Environment Agency, 2017

- Full service availability—system design, product supply, media changeouts, and disposal

- Effective operation in the presence or absence of oxygen

- Tailored system designs that align with individual operating conditions

- Reliable and predictable performance that enables remote operation

- Technical support throughout the operation