Electric submersible pumps

Maximize production with diverse ESP solutions

Maximize production in any well or environment

From simplifying installation to meeting temperature and viscosity demands, SLB has the right electric submersible pumps (ESPs) for conventional, unconventional, high-temperature, intervention-constrained, and offshore requirements. Maximize production, increase run life, and ultimately reduce system life-cycle costs with a selection of fit-for-purpose ESP systems.

Customize ESP well performance with local support. Access to SLB engineering expertise further optimizes ESP well performance. Conveniently located assembly, repair, and test (ART) centers provide quick delivery and assistance in all major basins. Artificial Lift Surveillance Centers (ALSCs) monitor alarms 24/7/365 for rapid diagnostics, recommendations, and troubleshooting.

Reda™ Agile™ compact wide-range ESP system

Get the compact wide-range ESP system that can navigate any well—and you’ll get more from your reservoir for longer.

Find out moreOur portfolio

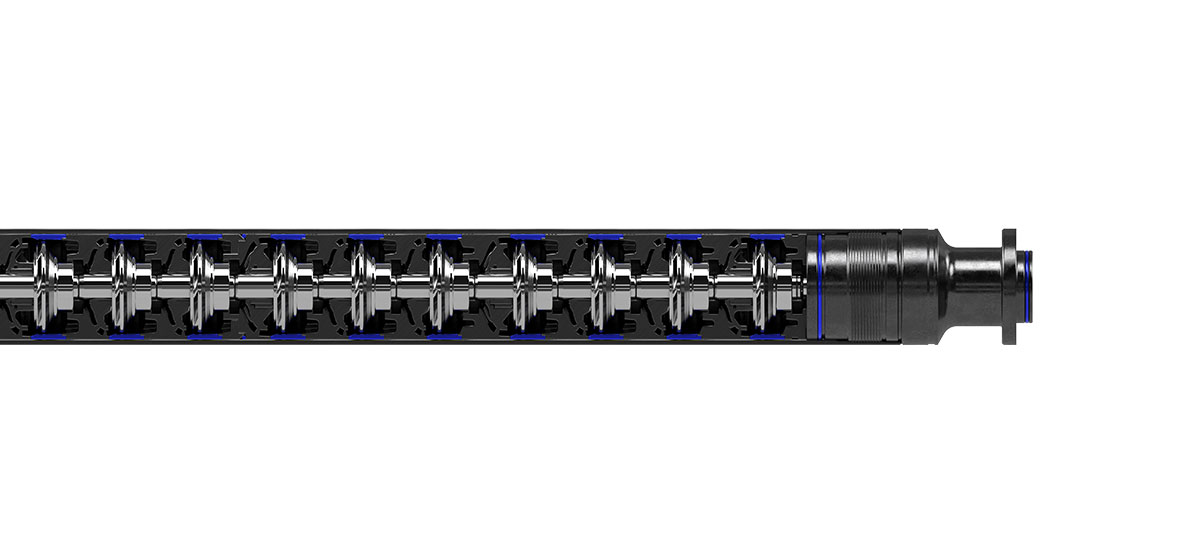

Reda Agile ESP system

New-generation ESP navigates any well and optimizes lift

MaxFORTE

High-reliability ESP system ensures more uptime in deepwater and other hard-to-reach well locations

ESPs for alternative deployment

Enabling rigless ESP retrieval and deployment to optimize well production

ESPs for geothermal wells

Application-specific technologies designed for high temperatures and abrasive environments

Reda ESP pump system

Optimize well performance with customized ESP solutions

Solids and sand control

PumpGuard intake sand control screen and valve assembly

Protect your ESPs, rod lift pumps, and gas lift completions from solids during production by cleaning fluid flow

Sand Fallback Shield

Protect your ESP pump from sand and solids during shutdowns