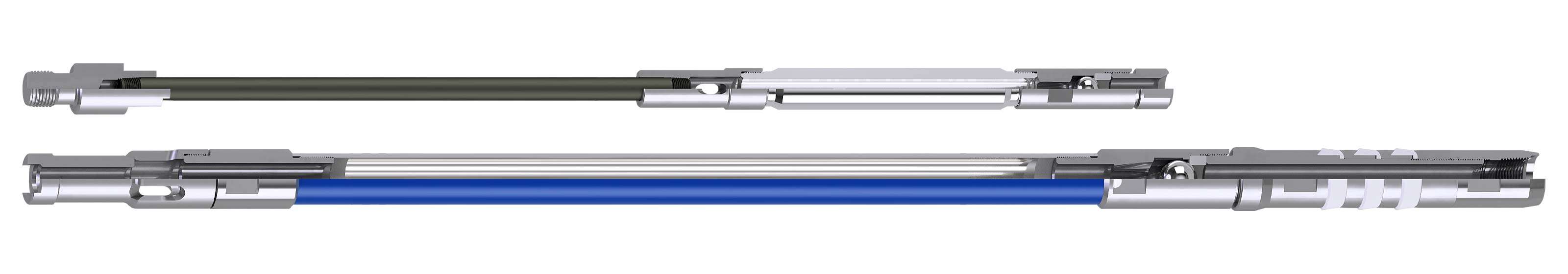

Sucker rods and couplings

Improve lifetime performance with maximum quality manufacturing

Choose high-quality and highly corrosion-resistant coated rods and couplings from Schlumberger.

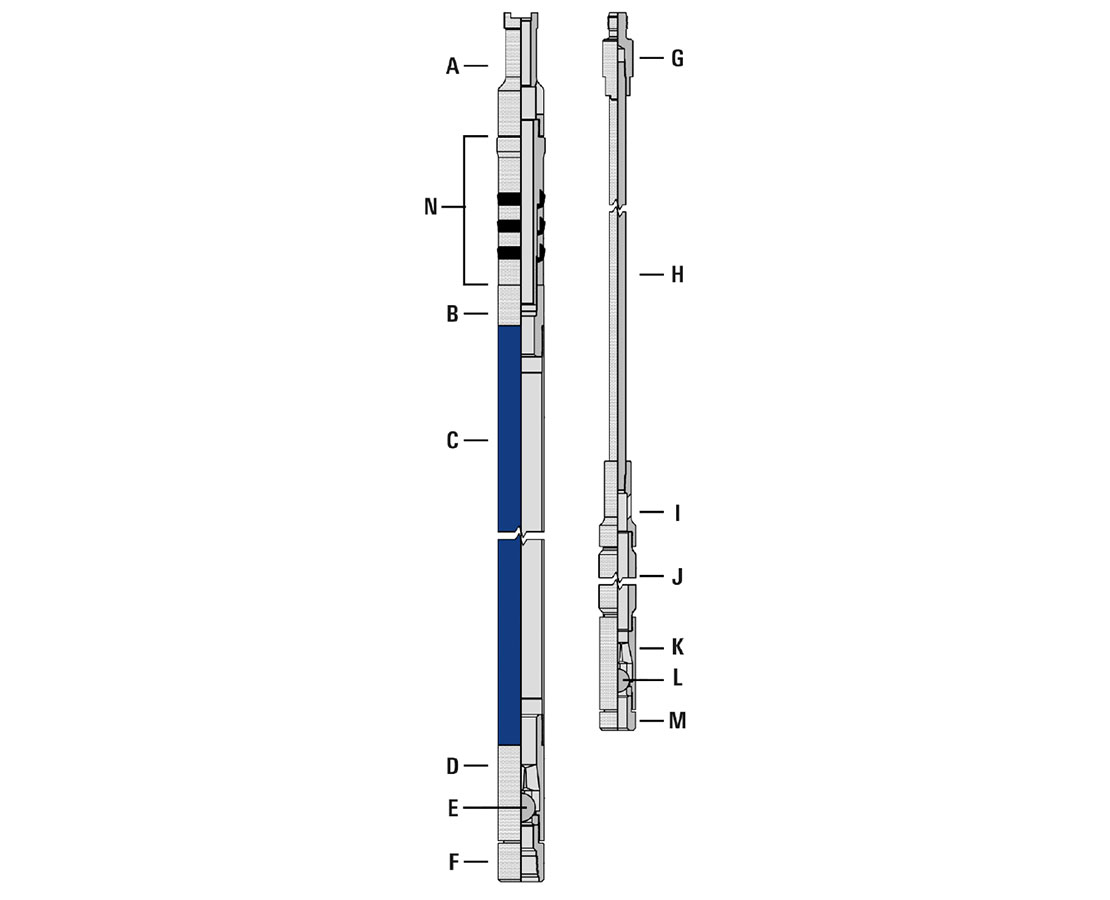

Suitable for shallow to moderate depths, RWA API insert pumps are thin-walled, stationary barrel, top anchor pumps recognized by API as a standard design. Because the pump barrel is threaded on the inside, there are fewer connections required, thereby reducing service costs.

The top hold-down anchor requires that fluid be discharged from the pump just above the seating nipple, which prevents sand and other solid material from accumulating and causing the pump to become stuck. Seating options include mechanical or cup types suitable for high temperatures and mechanical types to simplify well maintenance. A mechanical hold-down does not require repair unless major damage has occurred, whereas cups should be replaced every time the pump is unset. Both hold-down types follow the same procedure of setting by placing the weight of the sucker rods down on the pump and unsetting by lifting them up.

Metallurgy and component coatings can be adapted to well conditions to maximize pump life.