Reda ESP pumps

Electric submersible pumps that improve reliability and maximize flow

Wide range of applications

High-efficiency Reda ESP™ pumps are multistage centrifugal pumps used in a wide range of applications, both in the oil industry and beyond. In addition to typical oil, water, and brine production, they are used for booster service, ballast transfer, waterfloods, direct injection, cavern storage, mine dewatering, fire protection, irrigation, and commercial water systems.

Production rates from 200 to 95,000 bbl/d with boost pressures up to 6,000 psi

Corrosion-resistant coatings and stainless steel construction for corrosive environments

Increased efficiency and lift capability with high-performance ESP pumps

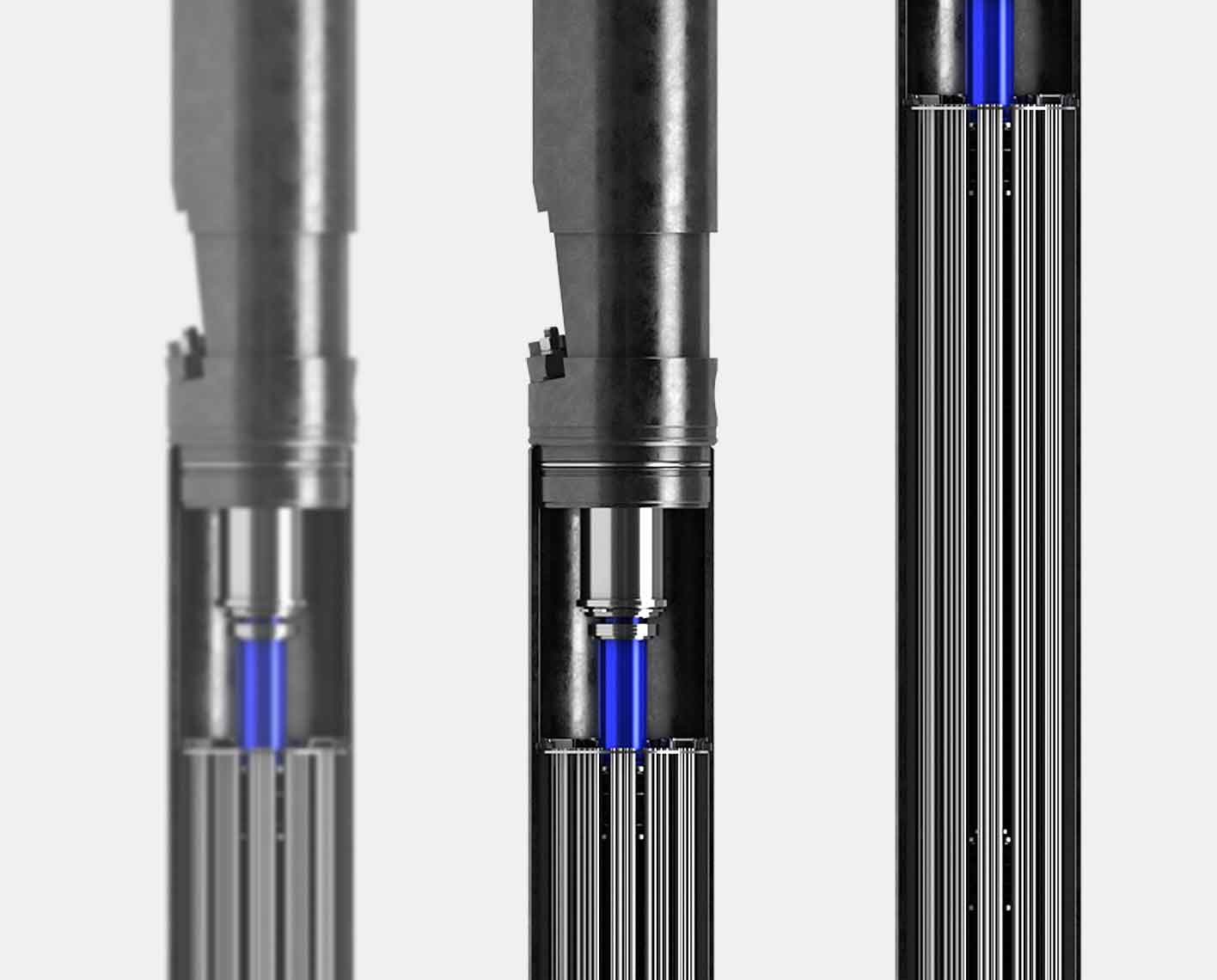

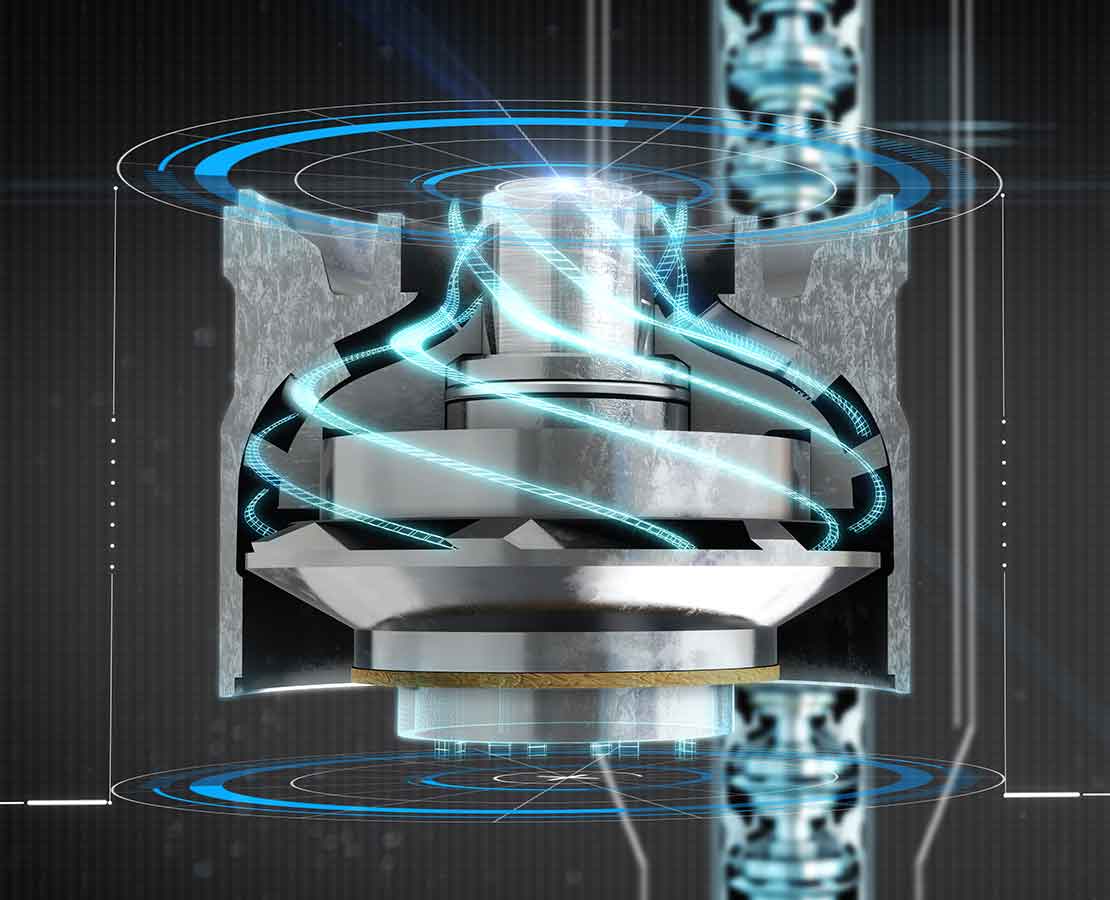

Each Reda ESP pump consists of a rotating impeller and a stationary diffuser that deliver hydraulic efficiency and optimal lift performance. We use computational fluid dynamics modeling and prototype performance verification to optimize internal pump geometry and flow profiles.

Assembled in a compression, factory-shimmed design, the pump shafts are matched at the factory to enable axial thrust transfer directly to the high-load protector bearing—eliminating time-consuming and error-prone field shimming procedures, reducing cost of ownership and installation, and enhancing ESP reliability.

Optimal performance in abrasive applications

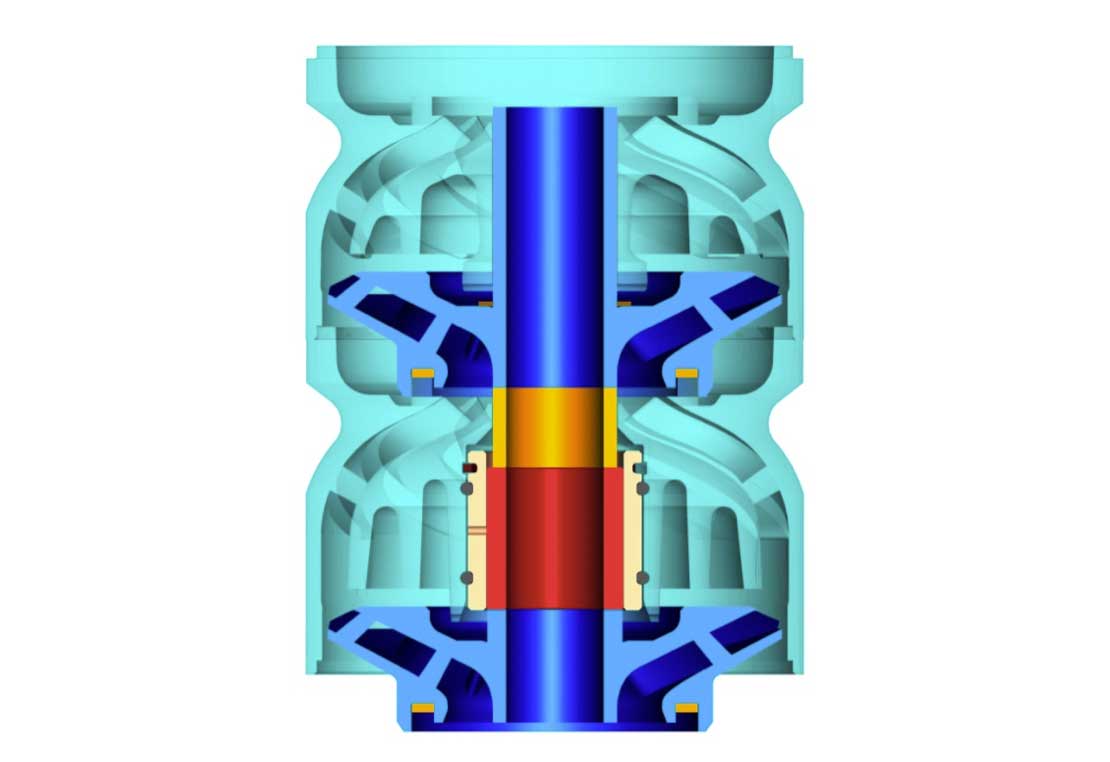

To maintain performance in corrosive or abrasive wells, our standard Ni-Resist stage material improves abrasion resistance, increasing pump life. MONEL® high-strength shafts enable greater horsepower delivery to the pump, improving lift performance.

The patented abrasion-resistant tungsten carbide bearings and compression-ring construction provide advanced radial stability even in the most challenging conditions, minimizing vibration and ensuring smooth operation and reduced wear. The bearings have repeatedly shown less wear during tests and field performance compared with alternative bearing materials over a wide range of well conditions.

Optional extreme abrasion-resistant stage materials and full bearing housing (FBH) upgrades enable field-proven designs for long run life in even the most rugged conditions.

Reda ESP is a mark of SLB.

MONEL is a registered trademark of Special Metals Corporation.