Conventional Gas Lift Valves

Economical options for land wells

Maximize production with time-tested technology

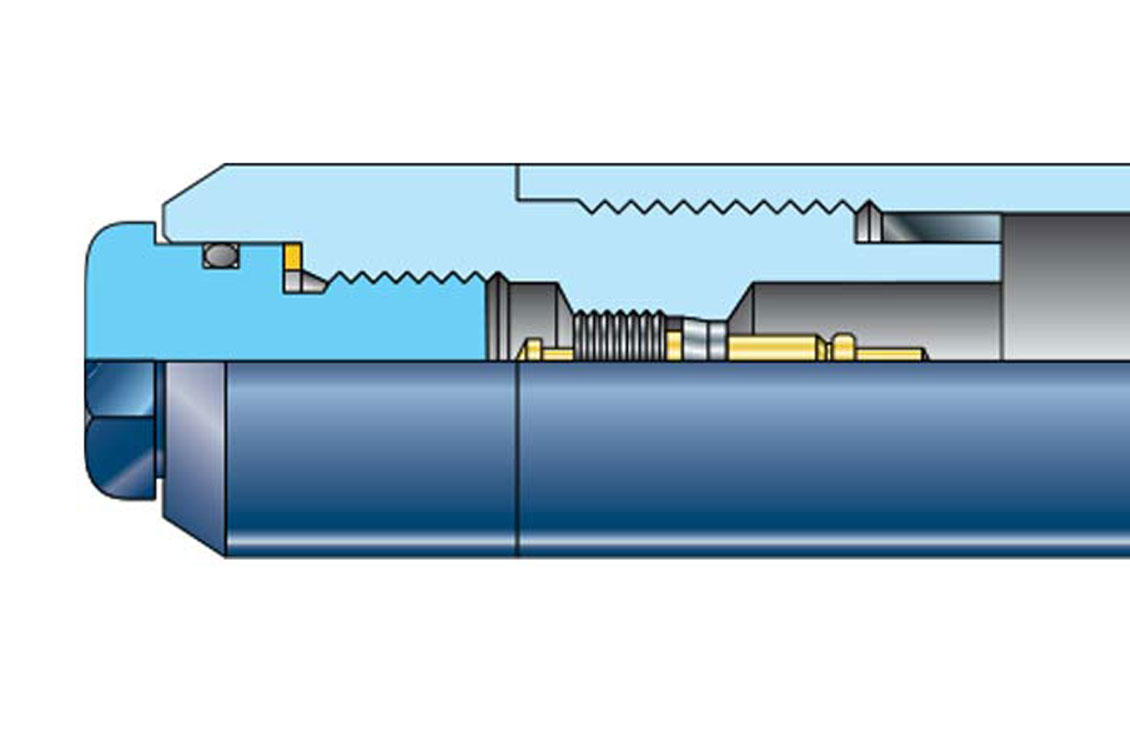

Camco conventional gas lift systems are some of the industry's most widely recognized, time-tested products and include injection-pressure-operated (IPO) and production-pressure-operated (PPO) models for continuous- or intermittent-flow production. Both IPO and PPO valves are available for either tubing or annular flow, depending on the design of the conventional mandrel. We also have conventional waterflood flow regulator valves and mandrels for single- and dual-string installations.

All of these valves are manufactured to strict industry standards and have a variety of port sizes, offering a range of selected gas injection volumes and flow rates. Most have floating valve seats that let you change the choke size in a stock valve. This also simplifies valve repair and improves sealing capability compared with conventional seat arrangements.

Economically produce from predictable wells

Conventional gas lift valves are attached to the tubing, making them an economical option for shallow land wells, wells with small tubulars, and wells in which reservoir and production characteristics are predictable.

Material options

The valves are constructed from stainless steel, MONEL, or other premium materials and provide for low-cost redress and repair. They have a spring-energized or nitrogen-charged bellows with necessary force to hold the valves in a normally closed position. The injection gas or the production pressure entering these valves has the necessary opening force to overcome the precharged nitrogen in the bellows or the preset spring force.