DesignRite

Artificial lift design and optimization software

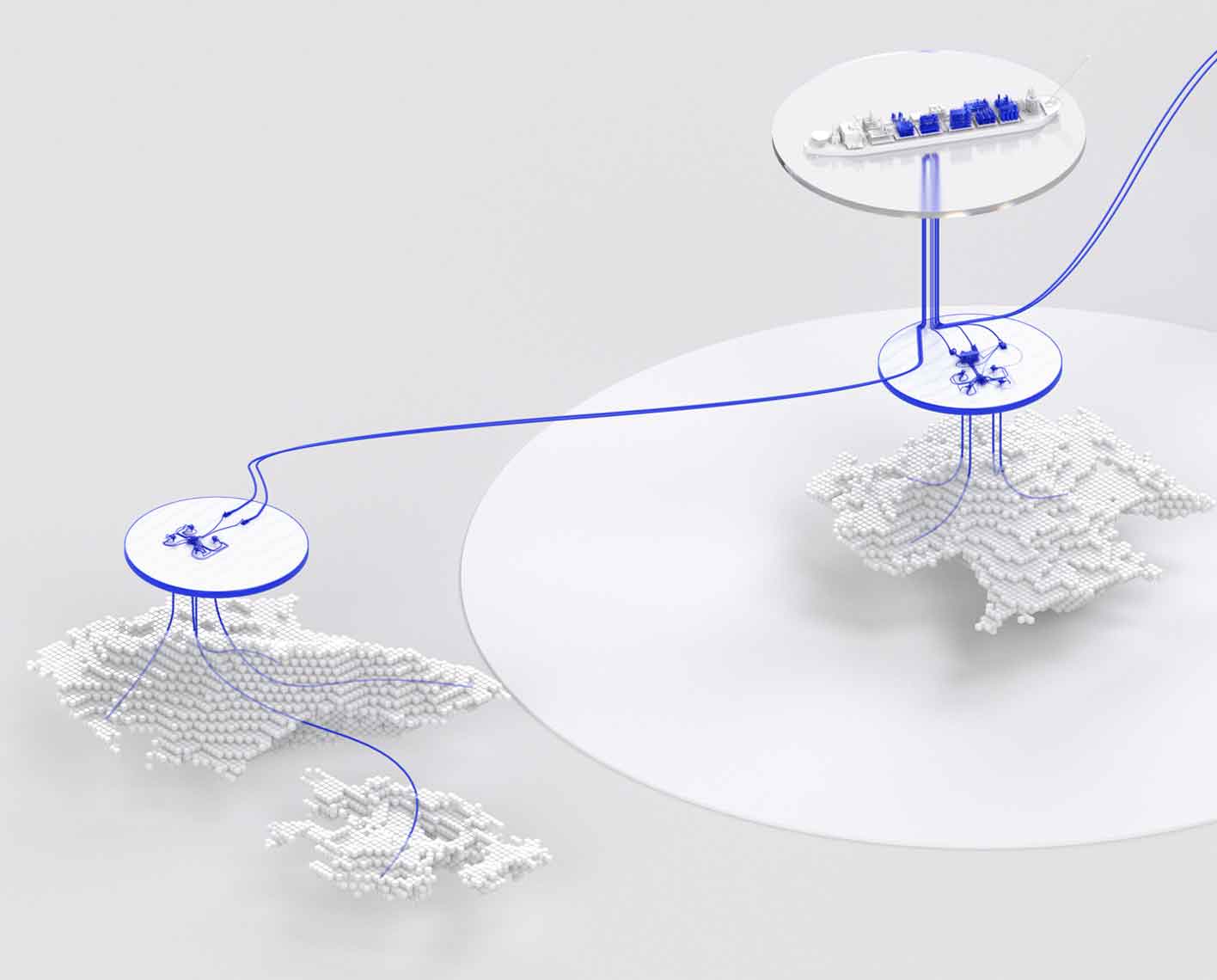

Design and optimize ESP and gas lift systems

Simplify the process of selecting electric submersible pump (ESP) and gas lift systems using the user-friendly DesignRite artificial lift design and optimization software. The software provides you with a step-by-step workflow to help determine and select the optimal solution for individual wells. The system uses both an ESP design mode and a gas lift design mode to provide you with a workflow for a wide range of ESP and gas lift systems.

Intuitive workflow and accurate performance prediction

Analyzing the performance of selected components is crucial to designing an efficient lift system. The sophisticated workflows of the DesignRite software analyze and size entire ESP or gas lift systems and use the input fluid, well, and reservoir information to accurately predict the inflow and outflow performance of the systems. Several sets of performance plots are provided to help determine the best-suited system to maximize production and minimize downtime.

ESP design mode

With step-by-step data entry, the software simplifies the process of designing an ESP—ultimately decreasing production downtime. The ESP design mode incorporates methods and equipment for low-GOR, high-GOR, and very-high-water-cut applications. Among the various design capabilities, the software allows pump selection based on the estimated pumping rate and includes motors available in a broad range of voltage ratings with multiple cable, protector, ancillary equipment, and surface equipment selections.

Gas lift design mode

The gas lift design mode helps engineers control the design of multiple types of gas lift systems, including injection-pressure-operated and production-pressure-operated valves. The software provides options for specifying gas lift injection, operating and unloading parameters, and valve spacing.