Manara electric ICVs in multilateral wells

Control flow from each zone in each lateral, individually

Recover more oil from multilateral wells with a smarter completion

Proven in challenging environments since 2014, Manara first-generation electric ICVs, which are equipped with in situ sensors, improve recovery by enabling real-time monitoring and control of multiple zones in each lateral of your multilateral well—without intervention and without time-consuming complications during installation.

The result is unprecedented levels of in-lateral zonal control and monitoring, all in real time, to maximize hydrocarbon sweep and recovery.

World’s first in-lateral real-time well cleanup in multilateral well, Saudi Arabia

Manara ICVs provide Saudi Aramco with game-changing zonal monitoring and control capability to optimize well cleanup.

Read the case studySave time and money on production optimization

Unhindered by wellhead and packer restrictions that limit the number of ICVs and downhole gauges in a conventional completion, Manara ICVs and their in situ sensors enable real-time, continuous measurements and infinite control of multiple compartments or zones in each lateral.

The downhole intelligence and control capabilities are combined with surface intelligence to deliver

- water holdup measurements at the sandface, ensuring efficient well cleanup

- dial-a-rate capability in each zone to ensure optimal reservoir drainage

- 24/7 real-time production logging to highlight unforeseen production changes.

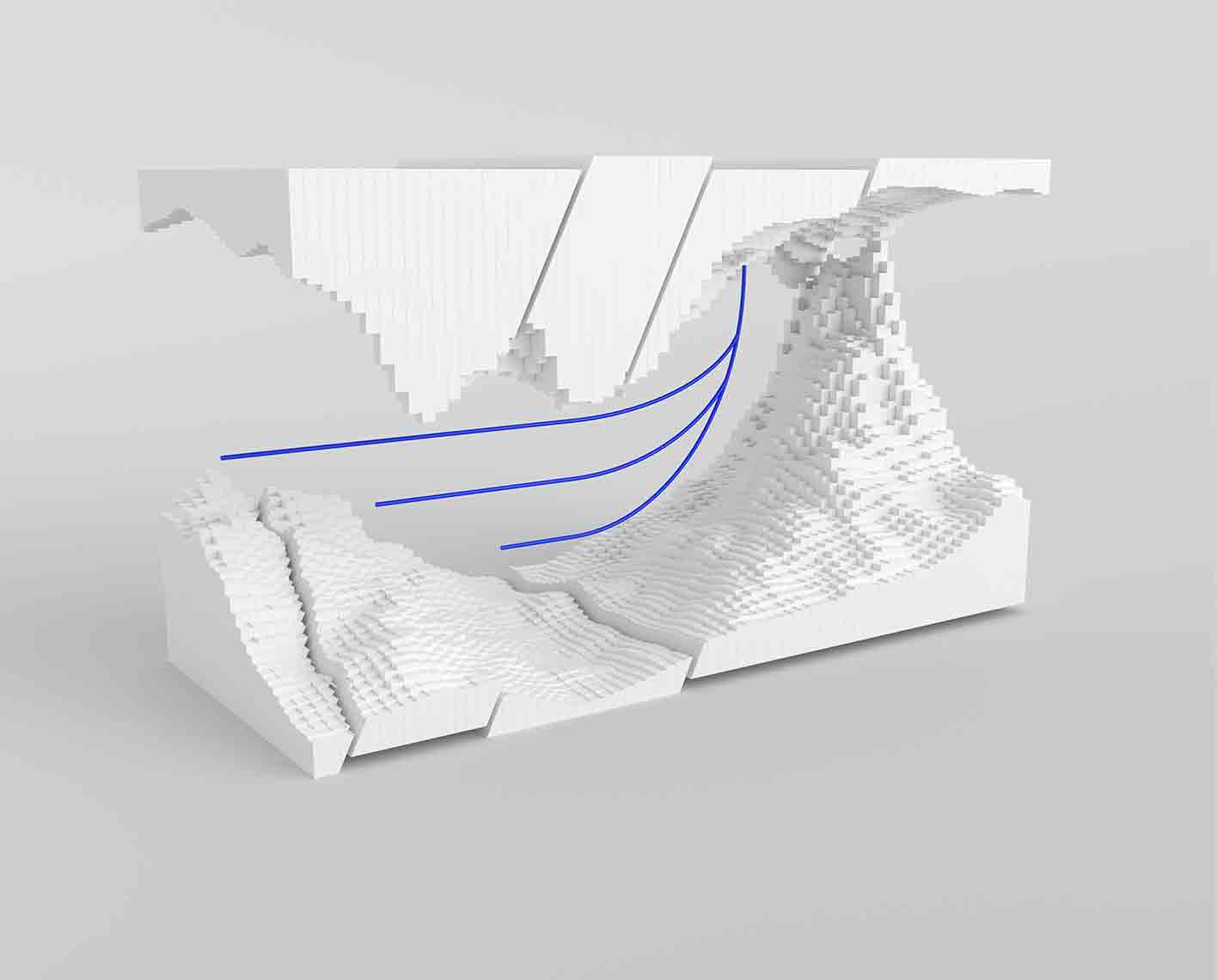

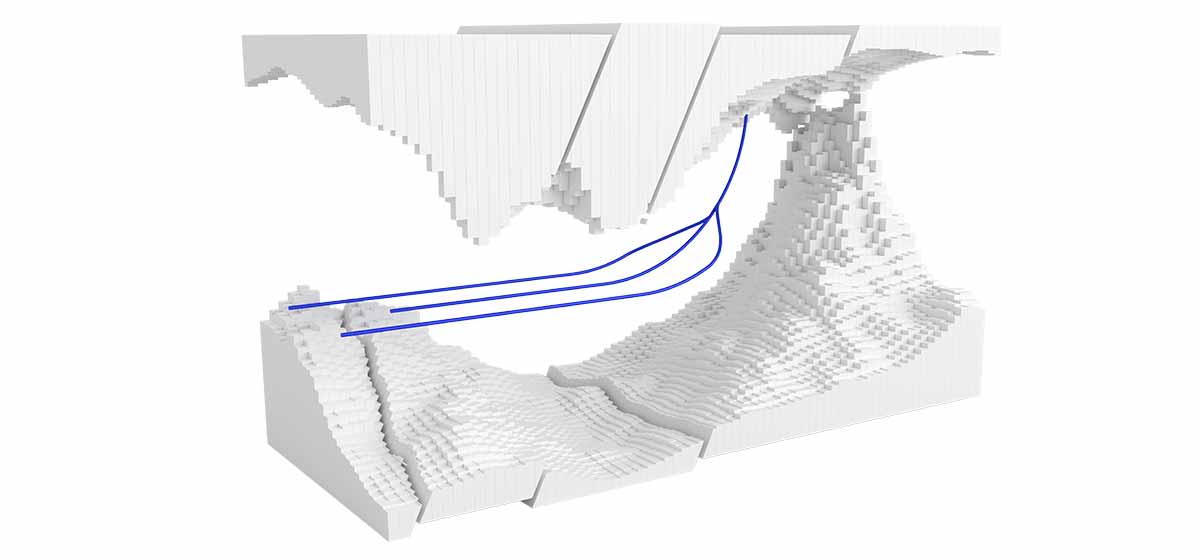

Interventionless control of water holdup and fluid flow rate by zone—even in long laterals

As the well produces, the intelligence continues to measure flow and recommend choke settings to maintain optimal performance over time with dynamic changes in the reservoir behavior—all in real time, without any interventions such as production logging.

That means, for example, that instead of shutting off an entire lateral because of water or gas breakthrough, it’s possible to identify the problem zone, choke it back, and continue to produce from the deeper zones you invested time and money to reach. The optimization workflow monitors flow rates, water holdup, pressure, and temperature at the sandface to enable optimizing all ICVs without the “experimentation” required in less sophisticated systems. The overall effect is improved recovery across all your laterals—and less complication for reservoir and production engineers.

Simplified installation improves reliability and flexibility

A single electric control line connects each Manara ICV to the next and the entire system to the surface, minimizing connection points and splices, simplifying installation, and increasing reliability. Intellitite™ downhole dual-seal dry-mate connectors eliminate potential leak paths, a common issue with monitoring systems. Power and data are transmitted wirelessly across junctions via inductive couplers.

The inductive coupler connects the lower and upper completions, simplifying installation and subsequent interventions if required. Eliminating the control line across the junction enables running in the lower completion on drillpipe. The pipe can be pushed, pulled, and rotated to overcome friction and reach target depth in extended-reach wells without fear of damaging control lines, removing any restrictions on the length of the wellbore. Subsequently, the upper completion is installed, and the coupler establishes electrical connection between the two.