Real-time fiber-optic interpretation and analysis

See clearly. Act confidently.

Fiber-optic sensing offers tremendous potential—but unlocking it hasn’t been easy

Distributed fiber-optic monitoring provides unmatched visibility into the reservoir.

Yet in many operations, its value remains out of reach. That’s because operators face four key challenges:

- limited access to reservoir zones

- installation complexity

- massive data volumes

- time-consuming interpretation and analysis required to make sense of it all.

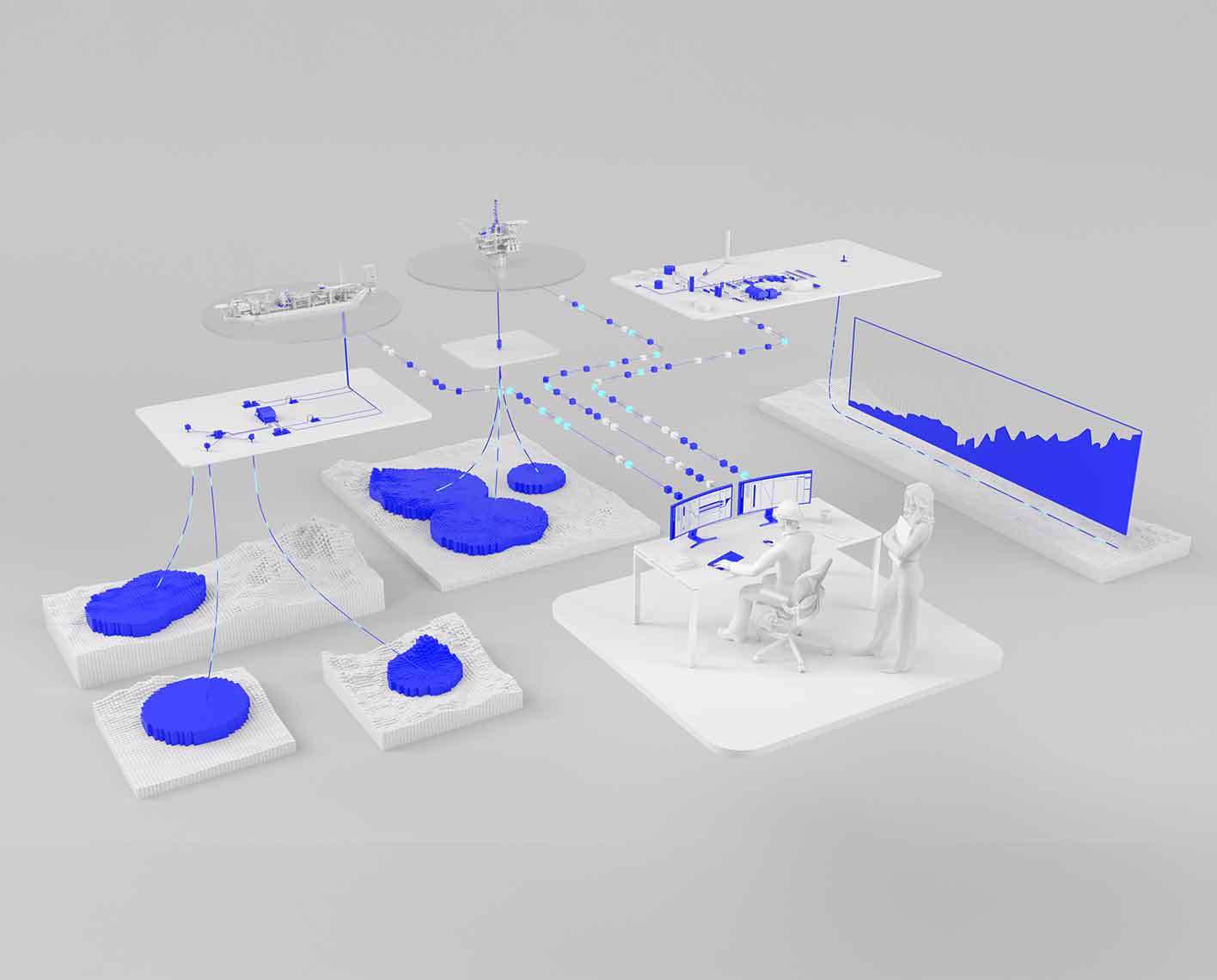

SLB removes these barriers to well and reservoir surveillance—end to end

A unified digital and hardware offering, Optiq™ fiber-optic solutions, enables you to extract meaningful production intelligence from fiber-optic systems—quickly, continuously, and reliably.

At the heart of this system is Optiq real-time (RT) fiber-optic interpretation and analysis, which transforms raw distributed temperature, acoustic and strain sensing (DTS, DAS, and DSS) data into operational clarity—automatically, at the edge. The result? Faster visibility into production behavior, injection effectiveness, and well integrity across the full length of the wellbore.

Automated Optiq RT interpretation and analysis workflows available today include

- multiphase production profiling

- injection profiling for water, gas, or CCS injectors

- automated leak detection for casing, tubing, and gas lift valves.

Continuous monitoring across the reservoir

Gain uninterrupted insight across the wellbore, including horizontal and deviated sections, with full fiber coverage supported by our deployment technologies.

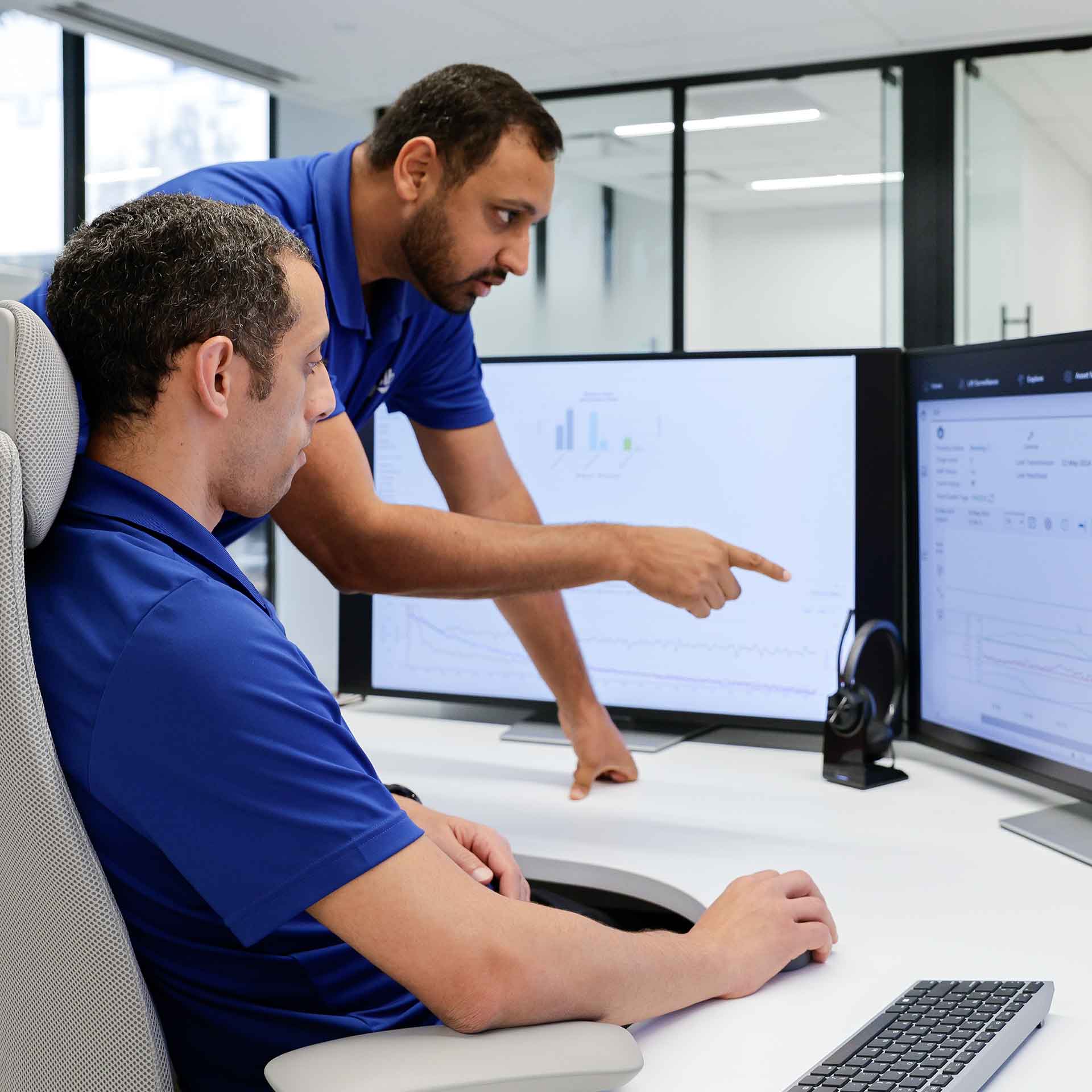

Real-time visibility without the wait

Interpret and analyze fiber-optic data as it’s captured, using edge automation that eliminates delays and manual interpretation workflows. Understand flow behavior, injection performance, and well integrity in real time.

Faster, more confident decisions and lower risk

Reduce uncertainty and operational risk with clear production intelligence that enables immediate response to changes in well conditions.

Simplified workflows, scalable architecture

Enable fiber-optic monitoring where it matters most—whether in oil and gas, geothermal, or CCS wells

To ensure full coverage of the reservoir, even in the most complex completions, SLB provides a portfolio of enabling technologies that simplify optical fiber deployment and maximize data integrity.

Multitrip Deployment systems

Control Line Wet-Mate (CLWM) connector

Enables pumped fiber deployment without splicing across multitrip completion junctions—even in gravel-packed wells—increasing reliability and reducing intervention time.

Electris™ downhole fiber-optic wet-mate connector

Seamlessly reestablishes fiber-optic connectivity to the lower completion after upper completion workovers, including in gravel-pack, frac-pack, and stand-alone screen completions.

Fiber-Optic Cables

Optoelectric permanent downhole cable

Combines an electric conductor with fiber-optic lines in a single 1/4-in cable—supporting both power delivery and data acquisition.

Permanent fiber-optic cable

Provides robust DTS, DAS, and DSS transmission—even in HPHT, SAGD, and geothermal wells—using field-proven tube-in-tube construction.

Surface interface

Hybrid wellhead outlet

Securely terminates optical fiber and electrical pathways at surface—even in explosive or hazardous environments—supporting safer, compliant operations.

>2,300

fiber-optic installations worldwide>7,500

kilometers of cable deployed1995

the year of our first downhole fiber-optic installation