DynaForce

High-performance drilling motors

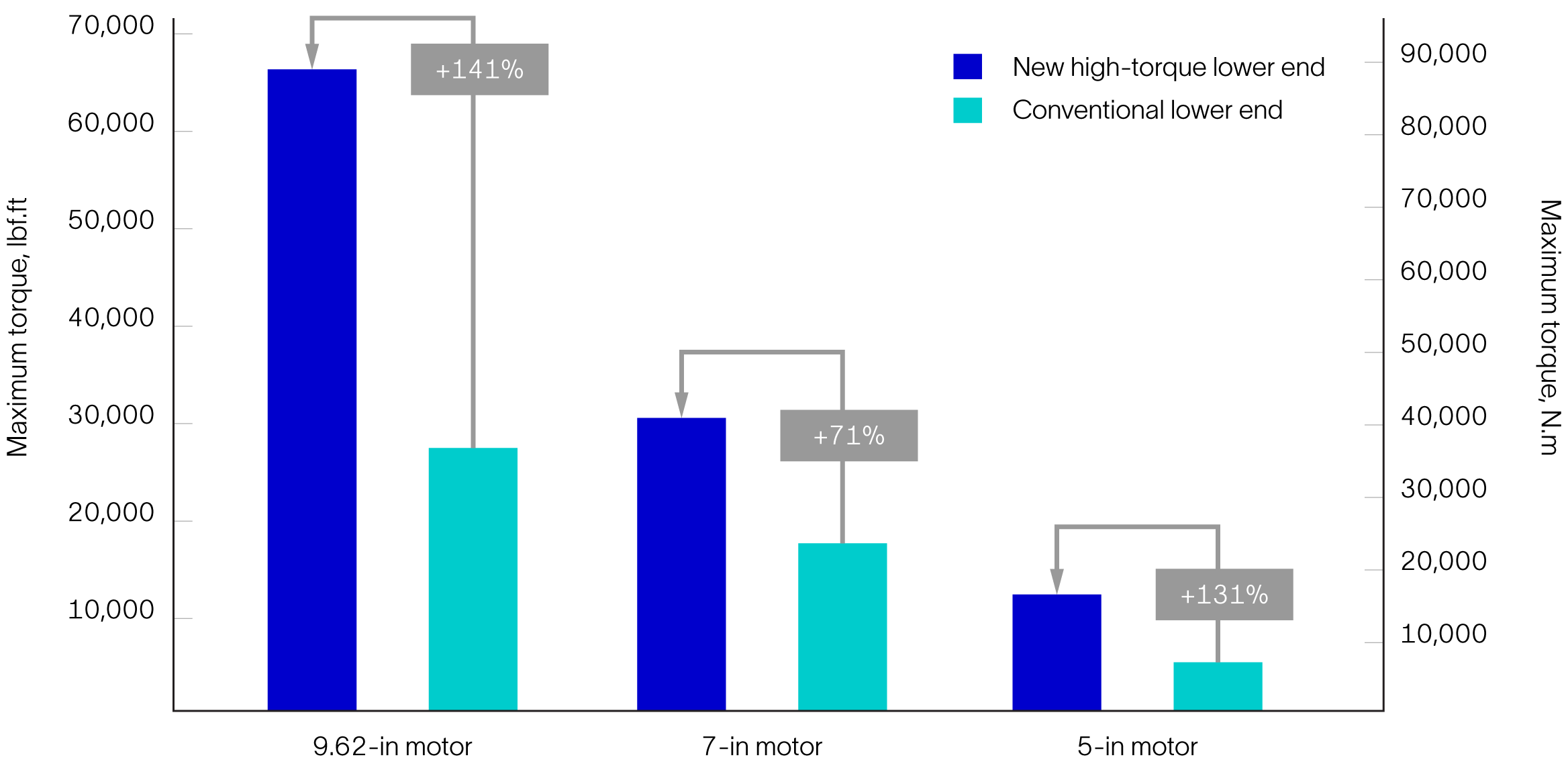

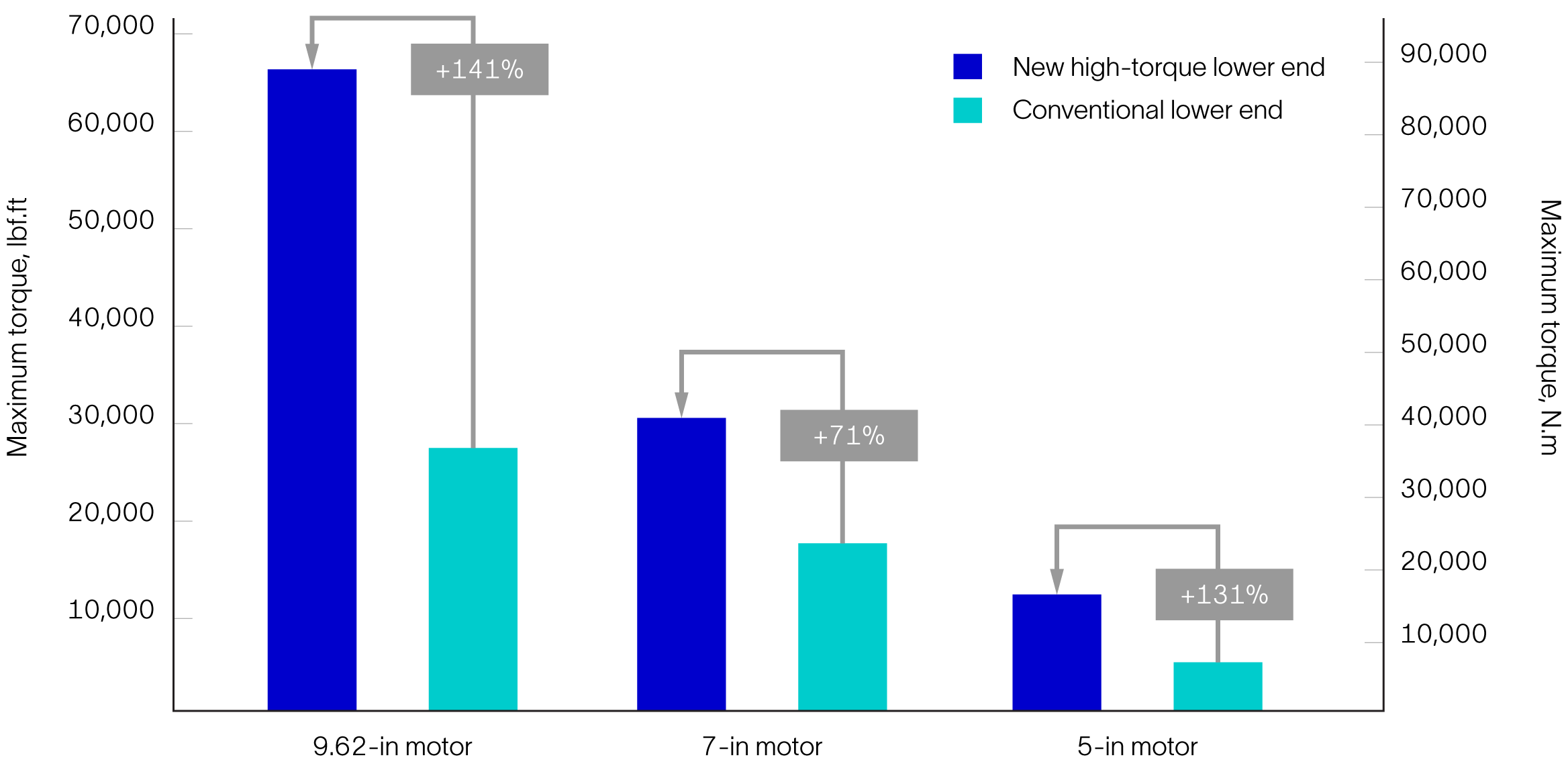

Outperforming conventional motors

DynaForce™ high-performance drilling motors excel in performance drilling applications, where precision, speed, and efficiency are paramount. Specifically engineered to handle abrasive and hard rock formations, they provide reliable operation in high-temperature wells, including geothermal, where extreme heat is a constant factor.

DynaForce high-performance drilling motors deliver maximum torque directly at the drill bit, ensuring superior performance and reliability in drilling applications. Engineered with proprietary technology, they outperform conventional motors in high-volume drilling, high-dogleg well profiles, and harsh environments.

Precision performance in geothermal wells

DynaForce motors are equipped with essential directional control capabilities required for precise navigation into fracture zones within geothermal wells. To enhance performance and reliability in directional geothermal wells, high temperature boot seals are included as a key feature. For vertical drilling in geothermal wells, DynaForce motors may be paired with PowerDrive vorteX™ powered rotary steerable systems for increased power output and footage.

Improves ROP with increased torque output in hard rock

Optimizes performance in high-temperature vertical applications, including geothermal

Increases reliability with proprietary transmission design

Maximizes performance in powered rotary steerable system applications

High-performance power sections

While conventional power sections are commonly used for oil and gas drilling environments, high-temperature (such as geothermal) and high-torque applications require a more robust solution. To optimize drilling performance, DynaForce DTX™ thin-wall motor power sections are designed specifically for high-temperature applications and provide the high torque output needed to drill abrasive hard rock with a reduced risk of elastomer failure in high-temperature environments.

Unique DynaMic™ variable temperature power sections are designed to lower the internal heat generation in the elastomer, enabling the mud motor to drill further in challenging high-temperature wells.

High-performance elastomers

Elastomers are the most common point of failure for positive displacement motors, resulting in more than 50% of all unplanned trips. All DynaForce motor power sections seamlessly integrate with DynaPower motor elastomers for exceptional performance in downhole environments, including in water and water-based mud drilling fluids used for geothermal applications. SLB is committed to providing robust, high-performance solutions for downhole environments, including a wide range of fit-for-purpose elastomers and unique motor elements that reduce drilling time, extend tool life, and eliminate unplanned trips.

These include:

- DynaPower XE™ extreme-environment motor elastomer

- DynaPower XP™ extreme-power motor elastomer

- DynaPower XR™ extreme-wear-resistant motor elastomer

- DynaPower HR™ high-torque motor elastomer