Produce better-quality drilling programs in minutes.

Transforming drilling data management with DrillOps™ reporting

Published: 11/26/2025

Transforming drilling data management with DrillOps™ reporting

Published: 11/26/2025

Streamline reporting, eliminate manual entry, and achieve real-time accuracy with automation and integration

Today, data is more than just numbers on a screen—it plays an increasingly important role in delivering efficient and repeatable wells through key insights that drive operational efficiency, safety, and performance in drilling. DrillOps reporting was built on this foundation and is designed to maximize the insight extracted from data while minimizing manual effort. It simplifies workflows, eliminates manual tasks, and provides accurate data as a single source of truth, it helps operators and drilling contractors streamline reporting and provides the framework for fast, accurate decision-making. Whether at the wellsite or in the cloud, DrillOps reporting can unlock the power of data, ultimately driving better outcomes throughout well delivery.

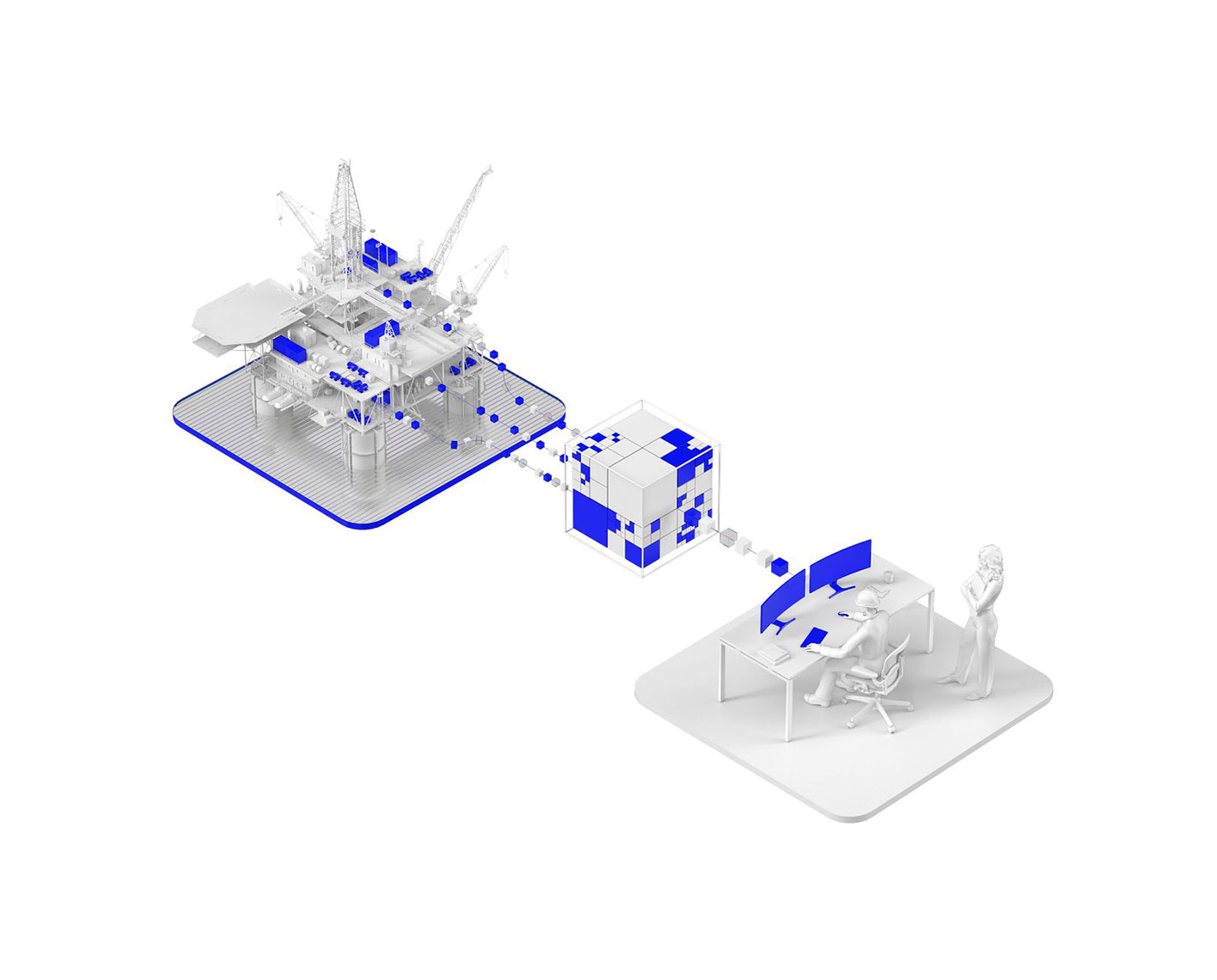

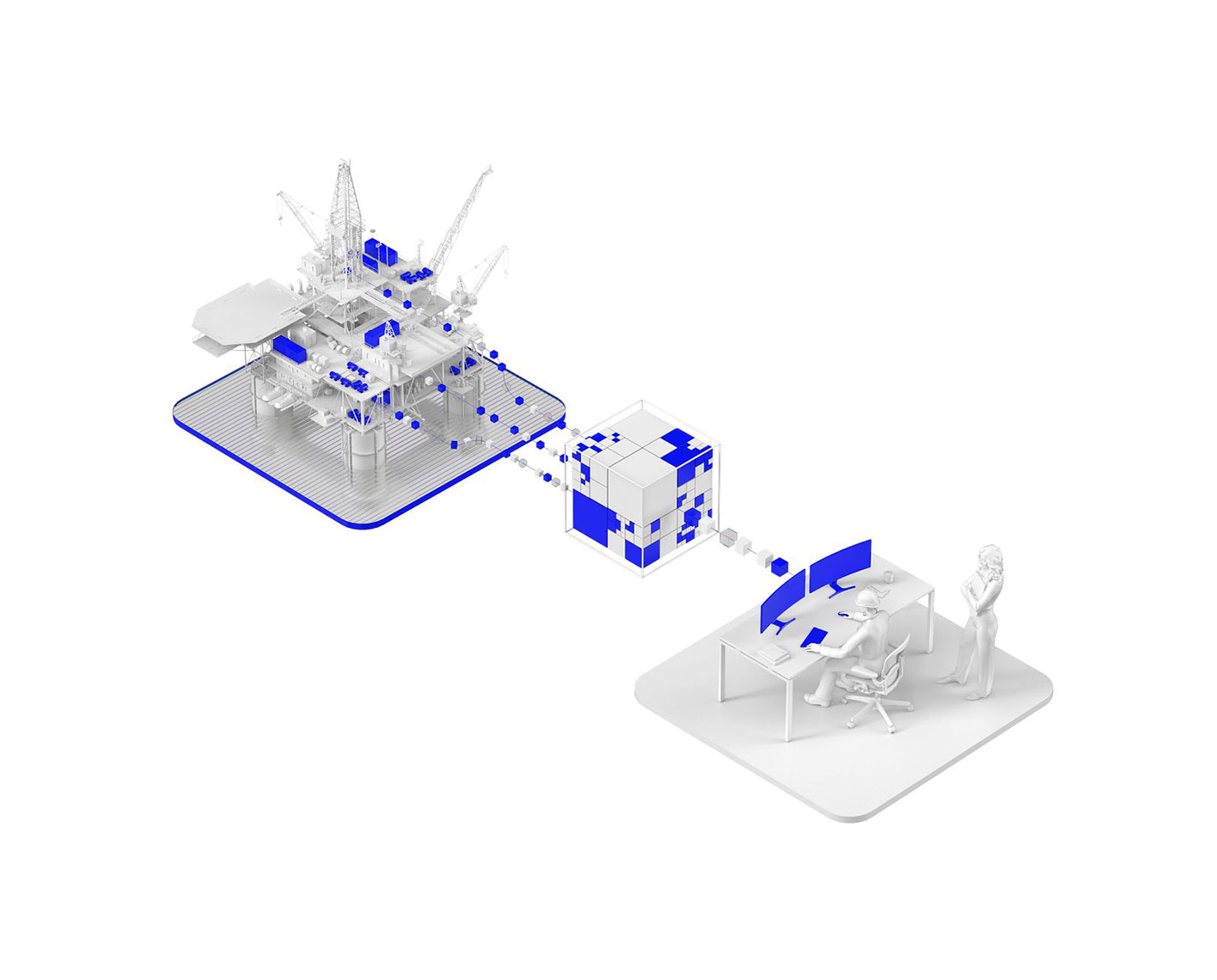

DrillOps reporting offers digital reporting and data exchange solutions tailored to all drilling personas. It automates data capture throughout the well lifecycle, greatly reducing the need for manual entry. Its open and extensible architecture enables seamless, bi-directional data exchange between systems, creating a unified digital ecosystem. It can transform reporting into an automated and efficient process, making reporting faster, easier, and more reliable.

Automation: reporting without typing

DrillOps reporting is built around one simple yet transformative goal: reporting without typing. By harnessing digital sources of data, it automates the process of gathering and entering information, streamlining the lives of rig personnel and drilling engineers while improving the quality of reported data. Whether it’s real-time data from sensors or files received via email and automatically populated into daily reports, DrillOps reporting ensures accuracy and consistency while minimizing human intervention. This shift toward automation saves time, reduces errors, and improves the quality of data used for operational decisions and future planning.

DrillOps reporting supports progression through four levels of reporting automation: manual, guided, semi-automated, and fully automated. Depending on your operational needs, you can transition directly from manual to automated reporting without the need for gradual progression. Even at the manual level, the solution reduces effort through its smart-parser system, which processes files like PDFs and spreadsheets. Guided reporting takes this a step further, introducing digital plans that guide users through the reporting process and automatically populate fields using real-time data connections. Semi-automated reporting employs rig state and operational state engines to fill in over 70% of daily activities, while fully automated reporting completes up to 95% of the daily drilling report (DDR) using an imported operational plan. This involves the combination of flat time with automated activity records to produce a more comprehensive operational plan or report. With only the drilling supervisor’s personal comments remaining manual, the solution achieves a balance between efficiency and a necessary human audit.

This automation delivers tangible benefits. By using real-time data from sensors, DrillOps reporting enhances data accuracy, reducing errors and ensuring reports are consistent with real-world conditions and comparable across assets. This, in turn, leads to better decision-making, as teams can rely on accurate data to plan operations and analyze historical performance. Additionally, automation reduces the time engineers spend on manual data entry and corrections, resulting in significant cost savings.

Seamlessly connect your drilling ecosystem with powerful integration

The innovative capabilities of DrillOps reporting are powered by its ability to take integration to the next level by seamlessly connecting not only to other SLB applications but also a wide range of third-party systems, enabling smooth data exchange and streamlined workflows. This connectivity eliminates redundancies, ensures consistency, and creates a unified ecosystem where information flows effortlessly between platforms, empowering teams to work smarter and faster.

An example of this is the integration with DrillOps performance insights which allows metadata to flow directly from DrillOps reporting for analysis, eliminating retyping and ensuring data consistency. At the heart of this integration is a powerful data ingestion framework that handles information from multiple sources. Real-time sensor data is processed instantly, while third-party daily reports are ingested automatically through an email-based system. Even unstructured data, such as PDFs and spreadsheets, is processed effortlessly by a smart parser, ensuring every piece of information, regardless of format, is captured and ready for use.

DrillOps reporting ensures data accuracy through its built-in quality assurance tools. Before data is shared with third-party systems or used in applications like DrillPlan™ coherent well planning and engineering solutions, it undergoes rigorous checks against predefined templates to verify accuracy and reliability. Advanced cognitive coding further enhances data quality by interpreting and recoding activity comments from historical wells, which ensures consistency and comparability with newer wells and enables DrillOps reporting to rebuild a well’s data with minimal input. These measures ensure high-quality, consistent data that stakeholders can trust to drive critical decisions.

Redefining drilling data management

DrillOps reporting is more than a tool—it reimagines how drilling data is captured, processed, and utilized. By combining advanced automation with seamless integration it helps operators simplify reporting, improve data accuracy, and ultimately make better-informed decisions. From reducing manual effort to building a unified data ecosystem, DrillOps reporting delivers the tools and capabilities needed to thrive in today’s complex drilling environments.

Ready to transform your drilling operations with DrillOps reporting? Discover how automation and integration can help you save time, reduce costs, and make better decisions. Contact us today to learn more or request a demo of DrillOps reporting.

Douwe Franssens

D&I Product Manager

Douwe Franssens holds a bachelor’s degree in civil engineering with a specialization in dredging technologies. He has over 35 years of experience in the oil and gas industry spanning engineering, real-time operations, and product development. Douwe has held various leadership roles in well planning, real-time solutions, and technology management across various locations throughout the Middle East, North America, and Europe. Currently, he serves as a product manager in the United Kingdom, where he leads product development for the DrillOps™ reporting portfolio.