Optimize your well’s production with a compact ESP system that fits deeper and accommodates flow rate changes.

ESP system overcomes high-DLS challenges in a Permian well

The mechanical flexibility provided by the Reda™ Agile™ compact wide-range ESP system enabled an operator to successfully navigate the high-dogleg-severity (DLS) sections of a Permian Basin well and place the ESP at the optimal depth. The ESP system reduced system shutdown events by 75% and improved system robustness by 76% compared with conventional ESP configurations, maximizing operational efficiency and performance.

In the Permian Basin, Strawn Petroleum Operating, LLC had faced challenges deploying a conventional ESP system in a highly deviated well as a result of pump setting depth constraints.

The well's high DLS at the target depth had restricted the installation of a conventional ESP system to a shallower depth because of the insufficient tangent length to deploy a 150-ft ESP string. The depth limitation resulted in several operational problems: suboptimal pump intake pressure, frequent gas lock events, inadequate motor cooling, and continuous cycle starts and stops.

These issues collectively diminished production efficiency and reduced the ESP system's reliability and performance. Therefore, an alternative solution was needed to mitigate these challenges while enhancing oil production and reducing operational costs.

Following a detailed analysis, SLB proposed the use of the Agile ESP system, an innovative and flexible high-performance solution. The system was designed to be deployed in a 50-ft tangent section beneath a high-DLS zone, where a conventional ESP could not have been placed because of space limitations.

The Agile ESP system enabled the Permian Basin operator to achieve the following successes:

- Optimal ESP placement: The operator was able to navigate a high-DLS section (DLS: 10.1°/100 ft), overcoming the critical limitations faced by conventional ESP systems, and place the ESP at the required setting depth.

- Enhanced operational stability: The Agile ESP system reduced system shutdown events by 75%.

- Improved system robustness: The Agile ESP system reduced motor cooling inefficiencies and gas lock occurrences by 76%, significantly improving operational continuity.

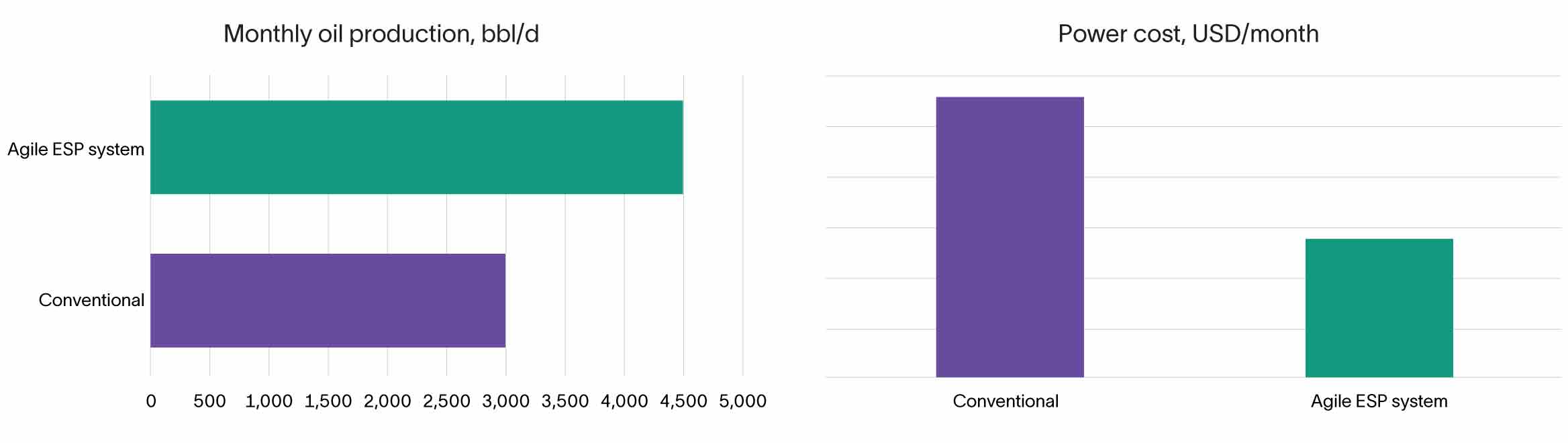

- Increased efficiency: Oil production was enhanced while overall power consumption was reduced because of the use of a permanent magnet motor.

The system delivered substantial improvements in both production and operational efficiency, demonstrating its ability to reliably operate in complex and challenging well conditions.