Produce better-quality drilling programs in minutes.

Eni using digital, AI, and automation to drill beyond limits

Eni are increasing their use of digital, AI, and automation technologies in their well planning and operations. Combining this with their aim of “drilling beyond the limits” has resulted in improved operations and new records for the areas involved.

Eni wanted to push performance to its technical limit. To do this they have implemented a new procedure to define the operational window. This involved capturing the constraints for each parameter and then defining the resulting operational envelope. This needed to be an iterative process to enable any suboptimal design, that would require re-engineering, to be highlighted. Eni chose DrillPlan™ coherent well planning and engineering solutions for this purpose. To then recommend and implement the best drilling parameters within the defined envelopes, Eni chose to implement DrillOps™ intelligent well delivery and insights solutions combined with DrillPilot™ equipment sequencing software and Neuro™ autonomous solutions.

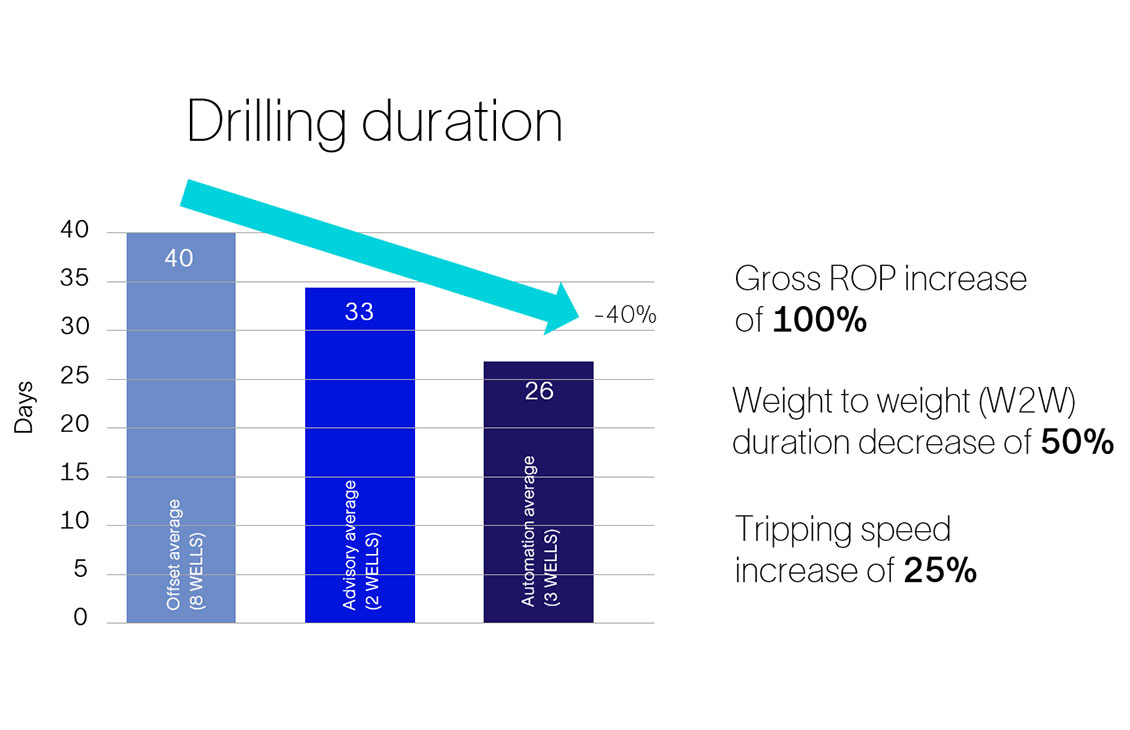

Eni has significantly enhanced their drilling operations by integrating digital, AI, and automation technologies in their well planning and operations, achieving new milestones. In the first quarter of 2024, Eni completed its first fully autonomous deployment in offshore West Africa, leveraging various advanced solutions—DrillPlan solutions for planning, DrillPilot software for tripping and connections, DrillOps solutions for drilling, and Neuro™ autonomous solutions for autonomous steering. Their use of these technologies enabled Eni to set a new global rate of penetration (ROP) record of 1,224 meters per day, reduce reaming and circulation before connection, and decrease weight-to-weight time by over 50%.

Eni has also implemented a service contractor incentive scheme to promote their crews’ operational excellence.

When tripping in cased hole, Eni has enhanced operational consistency and maximized speed, reaching up to 26 std/hour per hour. Operational safety has also seen improvements, with the presence in the red zone during tripping reduced from three instances on average, to zero.

DrillPilot software has been key in operating several drill floor machines in one seamless and optimized sequence, thereby minimizing human error and improving HSE conditions by reducing the need for personnel on the rig floor during pipe handling operations. DrillOps solutions were used to autonomously manage different drilling phases, delivering consistent and optimized performance while protecting wellbore integrity and adhering to company procedures.