OmegaX Gyro solid-state memory dual-gyroscope measures the Earth's rotation in just 32 seconds.

Digital gyro technologies enable record-breaking North Sea section

The integration of GyroLink™ definitive gyro-while-drilling service, TruLink™ definitive dynamic survey-while-drilling service, and OmegaX Gyro™ sold-state memory dual-gyroscope enabled a major operator to achieve accurate wellbore positioning and successfully drill the longest 12¼-in section ever attempted in the North Sea.

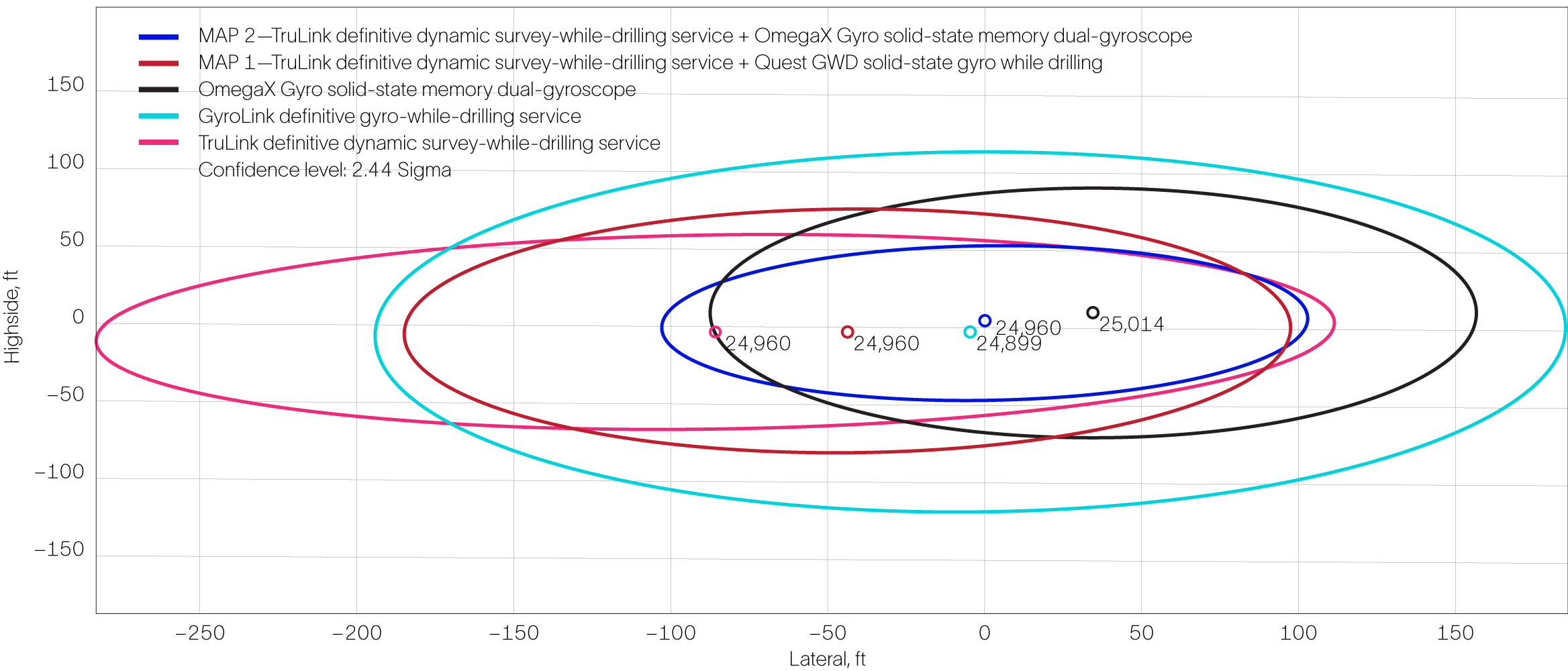

In the North Sea, a major operator aimed to drill a challenging well while staying within budget and time frame. The well needed to be accurately positioned within the target area of the reservoir to avoid the depleted heel area of the previous well drilled. Standard surveying techniques proved inadequate because of the small subsurface target window, which required a level of precision beyond the capability of any single survey system in this extended reach drilling application. Missing these targets would lead to reduced reservoir contact and an increased risk of intersecting already depleted reservoir zones. As a result, an innovative combination of survey technologies was required.

By leveraging multiple advanced survey technologies, the operator successfully drilled the longest 12¼-in section ever attempted in the North Sea. The integration of data from GyroLink service, TruLink service, and the OmegaX Gyro dual‑gyroscope achieved the most accurate wellbore positioning possible of the critical section. By continuously acquiring high‑quality data, this solution improved the integration of MWD with GyroLink service, allowing for the generation of a MAP 1 tool code for accurate real‑time wellbore positioning during drilling. Postdrilling, the combination of the OmegaX Gyro dual‑gyroscope and TruLink service facilitated the creation of a MAP 2 tool code, delivering a highly‑precise final wellbore position.