DigiScope

Slimhole measurements-while-drilling service

Generate power for more tools and transmit high-quality data in slim holes.

ConocoPhillips planned to drill a slimhole well in the Bull Moose field of the Bakken shale play in North Dakota, USA. The Red Wing 16-1H ST01 well was designed for an 8¾-in vertical section that extended to landing the curve, after which gamma ray correlation would be used to drill the 6-in horizontal section to TD in the middle Bakken dolomite formation. To drill the well in the target zone and perform formation evaluation, the operator needed continuous wellbore survey, shock and vibration, acoustic, and azimuthal density neutron data.

A BHA designed to collect this expanse of LWD data for the 6-in lateral needed to include an MWD tool that could simultaneously power all three LWD services, ensuring continuous real-time data for complete reservoir description. SLB provided the DigiScope slimhole MWD service that, in addition to its own power consumption, generates 110 W uphole and 110 W downholefor flexibility in BHA configuration.

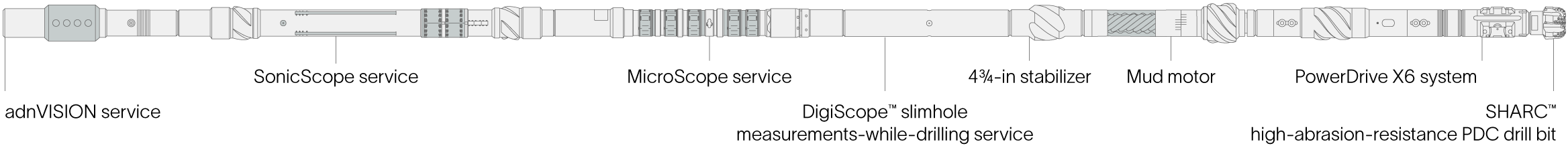

In addition to using the DigiScope service to collect wellboresurveys and shock and vibration data, the team was able to include MicroScope, SonicScope, and adnVISION services to ensure acquisition of all desired data in real time. The PowerDrive X6™ rotary steerable system (RSS) and a mud motor were included with an SHARC™ high-abrasion-resistance PDC drill bit from SLB for full directional control and reliability as the team used gamma ray correlation to drill the lateral section to TD. Then the BHA was picked up to relog the section from 20,350 to 11,347 ft MD.

ConocoPhillips moved forward with the slimhole BHA for the 6-in lateral section and was able to acquire all the required data in high resolution. With the DigiScope slimhole MWD service incorporated, the combination suite of LWD tools was powered continuously while logging at a speed of 140 ft/h and provided good-quality real-time and recorded mode data. The DigiScope service achieved 12-Hz signal strength and 6-bps physical bit rate during relogging.