Achieve real-time, high-definition wellbore architecture—from tophole to TD.

Definitive dynamic survey eliminates survey-related rig time and boosts well economics

SLB collaborated with Saudi Aramco to successfully qualify the TruLink™ definitive dynamic survey-while-drilling service, demonstrating the technology's precision that produced datasets from true while drilling—that is, as the BHA drilled the wellbore. Saudi Aramco predicts reducing survey time by 2 months per year and eliminating related activity time for stuck pipe by 3 months per year.

Work to minimize survey rig time

Static MWD surveys provide measurements every 90 ft along a wellbore. Current practice is to hold the drillstring stationary to allow the azimuth and inclination sensors to survey the wellbore. Survey time varies from 3 to 5 minutes per survey, and any movement to the drillstring compromises measurement quality and causes invalid data. This extends survey time into days on longer wells. Consequently, Saudi Aramco wanted to reduce or eliminate surveying rig time to improve drilling efficiency, minimize the drilling stuck pipe risks caused when pipe is stationary, and improve well economics.

Use definitive dynamic surveying while drilling

To achieve its goal to improve drilling efficiency, with particular focus on surveying rig time, Saudi Aramco collaborated with SLB to test and qualify TruLink definitive dynamic survey-while-drilling service. Three wells identified for official qualification runs included a vertical, curve, and lateral well profile. The qualification run objectives were to plot both TruLink service and gyro-survey data and compare inclination and azimuth values and trends.

Validate TruLink service, achieve gyro-equivalent precision

The three qualification runs demonstrated that TruLink service survey data were an excellent match to static surveys, within 0.5° inclination and 1° azimuth of static and well within respective error models.

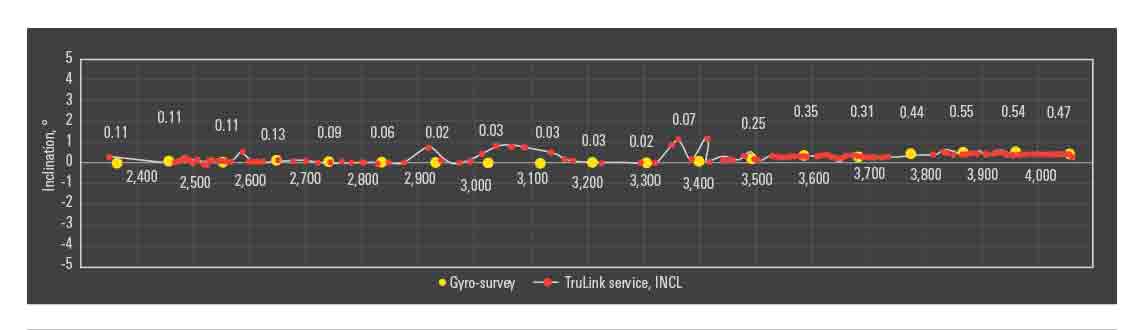

The first qualification run for TruLink service was in the vertical section using a rotary BHA, and the total footage drilled was 1,652 ft. Total pumping time on the tool was 28.65 h. Throughout the run, 126 TruLink service surveys were acquired. At section TD, a drop-down multishot-gyro survey was run and 44 gyro surveys were acquired. Both the TruLink service and gyro-survey data were plotted against each other with very promising results (Fig. 1).

The second qualification run was in a curve section, building from zero to 90° inclination. The BHA used was a PowerDrive Xceed ruggedized rotary steerable system to drill 2,862 ft over 137 pumping hours. Surveys acquired with TruLink service totaled 805 compared with 24 drop-down multishot-gyro surveys. Comparison between the datasets inclination and azimuth trends were close, as shown in Fig. 2.

The final qualification run was in the lateral section drilled with a motor BHA for a total footage of 1,000 ft over 42 pumping hours; TruLink service acquired data from 110 surveys. Compared against 311 pump-down gyro continuous multishot-survey data, the result was a perfect match, as shown in Fig. 3.