Hiway Flex

Customizable flow-channel fracturing technology

Improve production with fewer materials and less carbon intensity for greater efficiency and safer operations.

An operator in the Middle East sought to develop a deep, tight sandstone reservoir in the Ghaba Salt Basin using a horizontal well. Because of the proximity of the formation to the water-oil contact, the lateral section was strategically placed in a shaly interval above the main sandstone formation, with the goal of fracturing into the target zone. However, significant heterogeneity observed during drilling raised concerns about the efficiency of stimulation placement.

Previous attempts in similar wells had failed to achieve the desired fracturing design across all stages, with unclear reasons for the deviations. Additionally, screenouts impacted subsequent operations, requiring time-consuming and difficult postfracturing cleanouts in long horizontal wells. The operator needed a reliable solution to optimize stimulation placement, avoid screenouts, and maximize production.

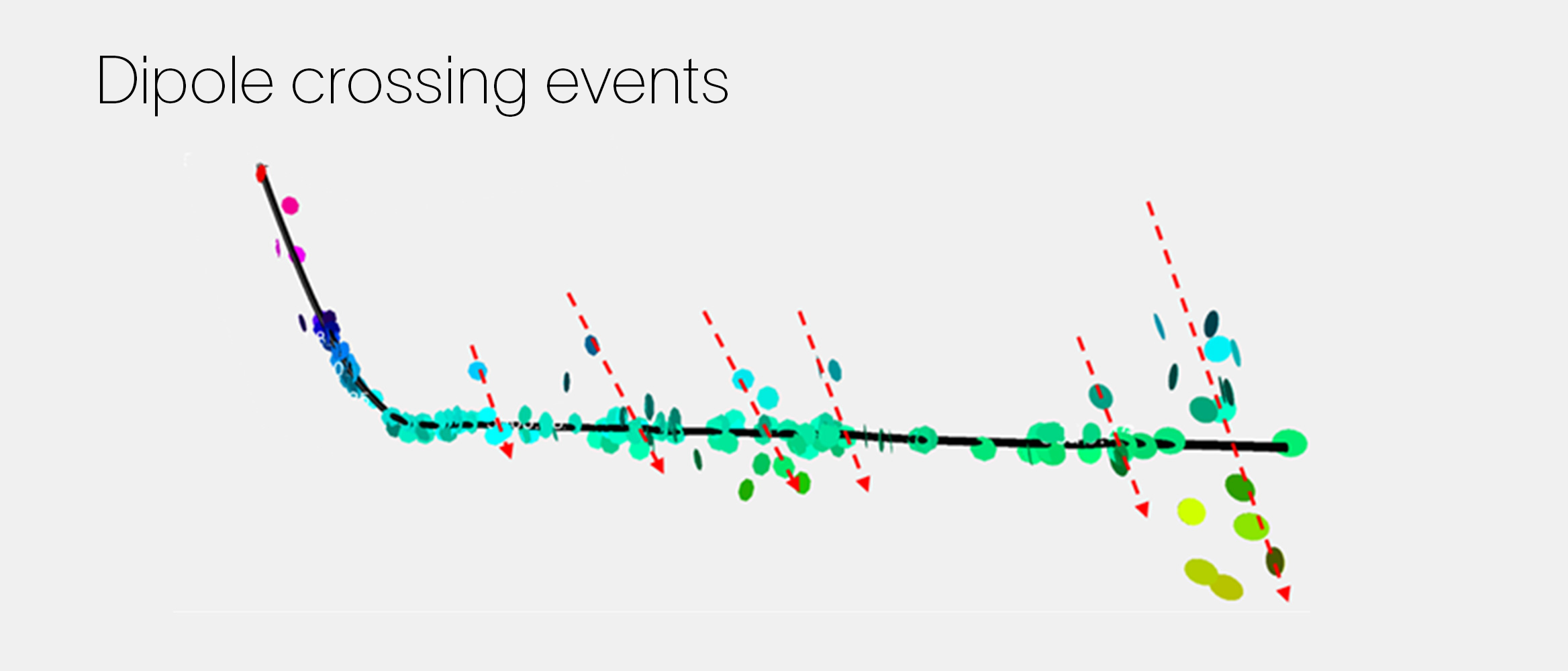

SLB proposed an integrated solution to address the operator’s challenges. The ThruBit Dipole acoustic service was deployed to provide extended acoustic measurements, enabling the identification of subseismic faults. The Acoustics Now facilitated fully automated interpretation and rapid turnaround, allowing the team to complete a comprehensive geomechanics analysis. This analysis provided critical insights into borehole permeability and injectivity through Stoneley wave analysis.

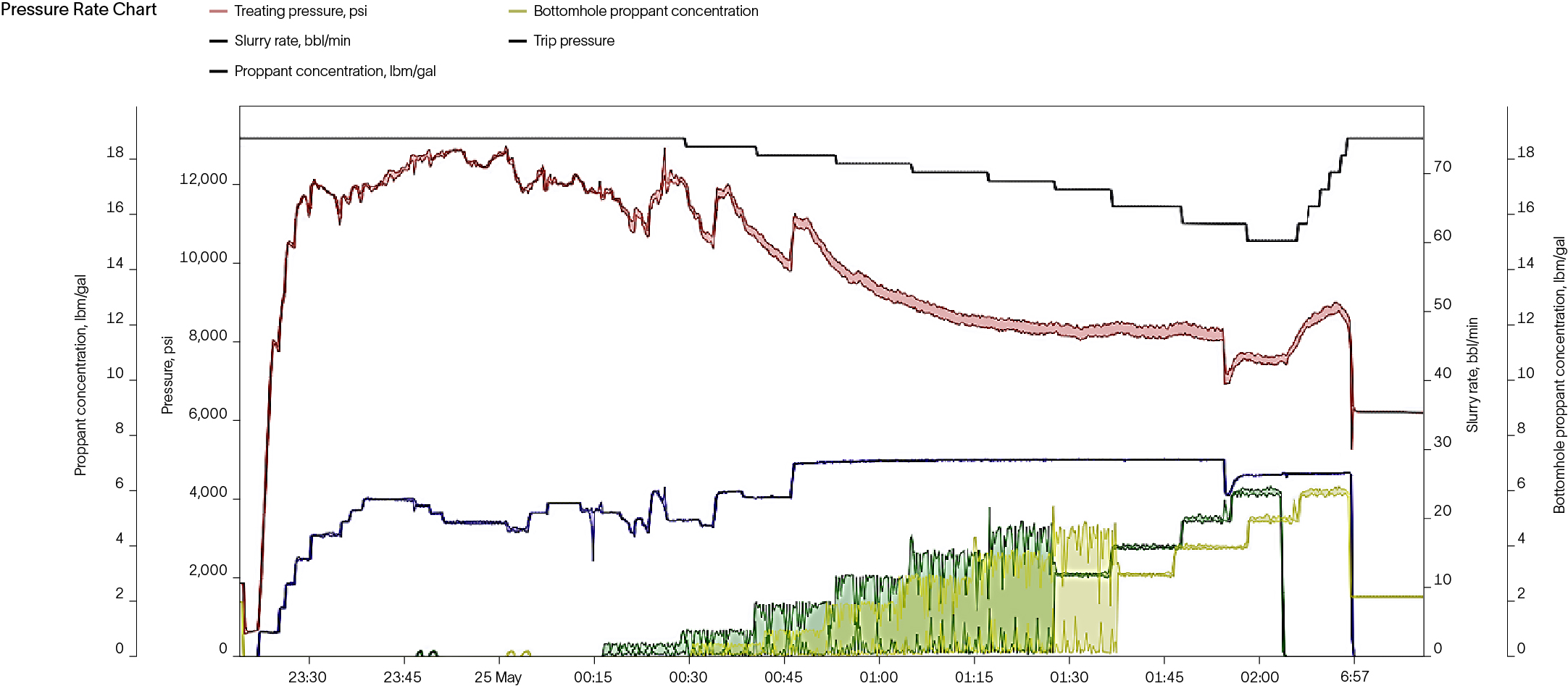

To optimize stimulation placement, SLB implemented the Intelligent Stimulation workflow, which considered reservoir quality, completion quality, and the stress regime to engineer perforation clusters. The Hiway Flex technology was applied during the early proppant stages to enhance fracture conductivity and minimize the risk of screenouts. Additionally, the BroadBand Sequence ensured effective coverage across all perforation clusters, as confirmed by postjob tracer analysis.

The results were exceptional. Over 700 metric tons (1.54 million lbm) of proppant were successfully placed across eight stages without any screenouts, significantly improving the frac stage cycle and overall operational efficiency compared to previous wells. When put on production, the well delivered over 2.7 times its forecasted output based on offset well data. This achievement not only resolved the operator’s challenges but also established a new standard for horizontal well development in similar reservoirs.