The two-stage hydraulic fracturing pilot in the Ghazij Formation demonstrated the potential of advanced technologies and workflows to unlock gas reserves in a challenging laminated carbonate-shale system.

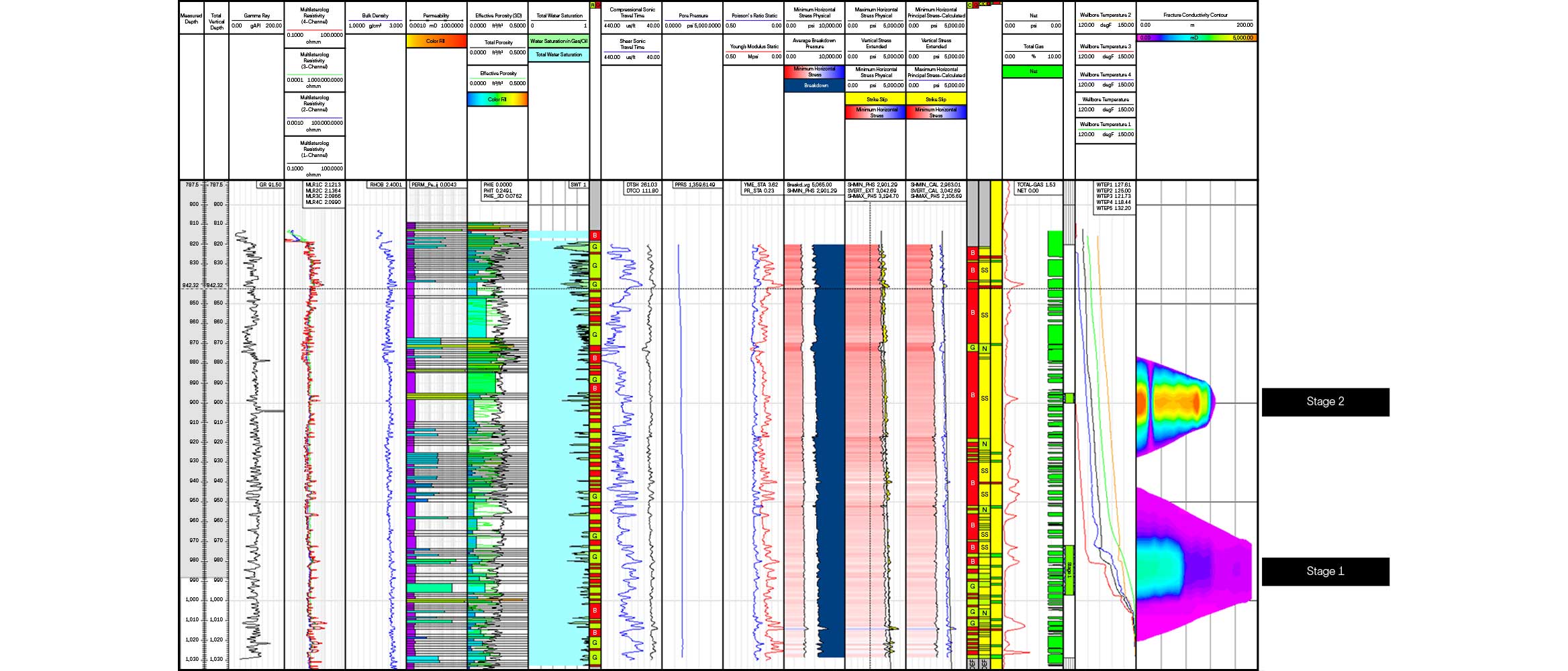

The SLB Intelligent Stimulation workflow integrated the available log data, including the MEM from Techlog™ wellbore software into Petrel™ subsurface software to apply advanced optimization workflows. This approach allowed SLB engineers to design and execute a more effective Stage 2 treatment. The hybrid design, which combined a high viscosity friction reducer (HVFR) and crosslinked fluids, was specifically tailored to the reservoir’s characteristics. The HVFR pad minimized net pressure during the initial stages, limiting early fracture height growth, while the crosslinked slurry and tip screenout strategy built near width and durable conductivity. Higher breaker loading and capillarity-control additives, such as methanol and surfactants, accelerated cleanup and reduced water block, resulting in faster flowback and higher gas production.

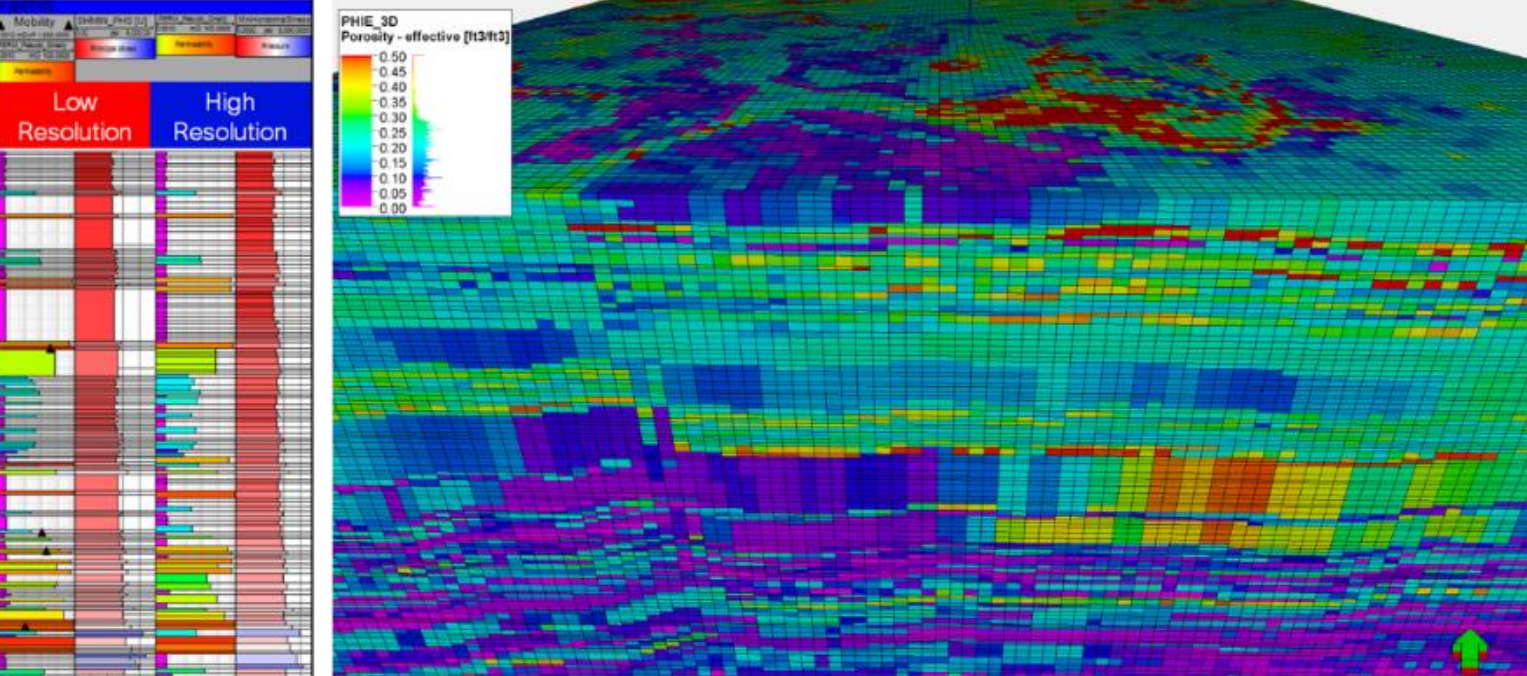

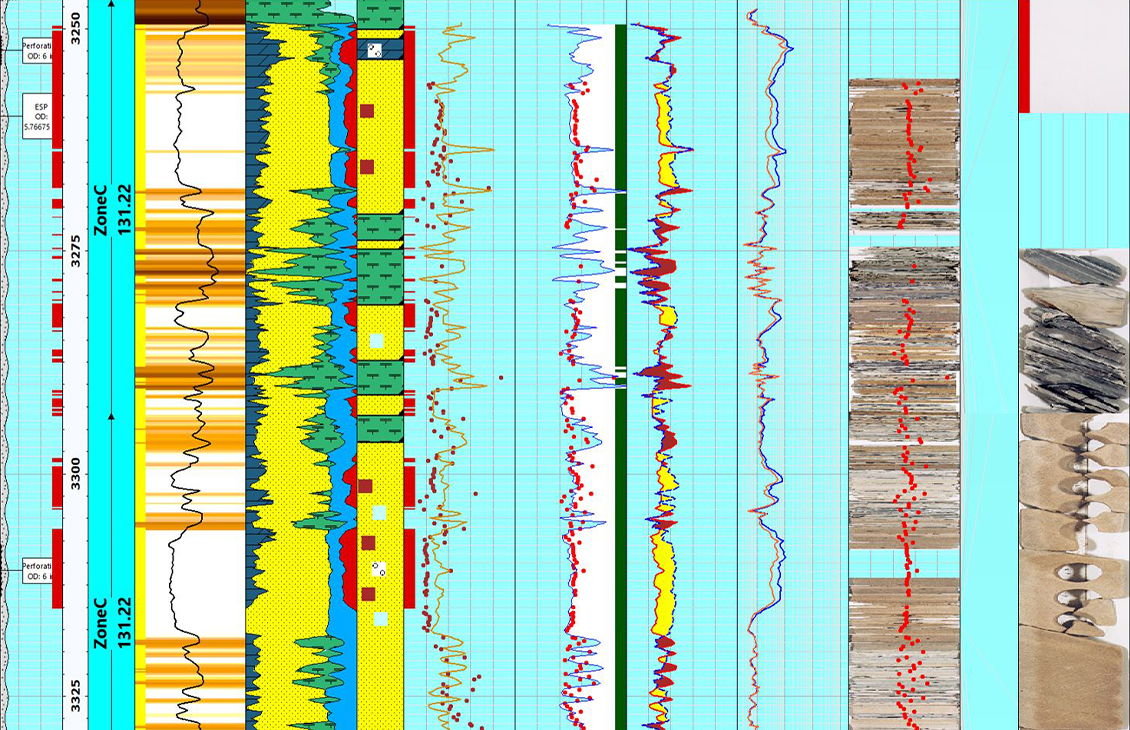

Techlog software was instrumental in building a one-dimensional MEM that integrated core and log data to define the stress and rock property profiles of the Ghazij Formation. This MEM provided critical insights into the reservoir’s vertical heterogeneity, avoiding excessive fracture height growth into the low-permeability shales. Petrel software was used to integrate geological, petrophysical, and geomechanical data into a high-resolution static model that preserved the lamination-scale heterogeneity of the reservoir. This model served as the foundation for fracture and flow simulations, enabling the team to accurately predict how fractures would propagate within the laminated system. By incorporating the MEM and other reservoir data, Petrel software ensured that the fracture designs were tailored to the unique characteristics of the Ghazij Formation, improving design fidelity and execution accuracy.

Kinetix™ reservoir-centric stimulation-to-production software was used to simulate hydraulic fracture geometry and optimize the treatment design for both stages of the pilot. In Stage 1, Kinetix software helped validate the conservative design by predicting net pressure trends and fracture geometry, which were later calibrated using DataFRAC™ fracture data determination service. For Stage 2, Kinetix software enabled the team to refine the pumping schedule and proppant strategy. The optimized design included a hybrid HVFR pad followed by a crosslinked gel system, a deliberate tip-screenout (TSO) strategy, and a single‑mesh ceramic proppant. These refinements were modeled in Kinetix software to ensure that the fractures would achieve the desired width, conductivity, and containment. The combined use of these technologies and workflows delivered exceptional results. Stage 2 achieved a markedly stronger net pressure response, resulting in a wider and more conductive fracture, and over three times higher early gas production compared to the baseline Stage 1. The optimized design also tripled the modeled conductivity, from 1,386 mD·ft in Stage 1 to 4,538 mD·ft in Stage 2. Surveillance data, including bottomhole pressure matching and post‑DataFRAC service temperature log interpretation, indicated that the fractures were placed as intended and appeared vertically contained.

The success of this pilot has provided a valuable framework for future wells, demonstrating the potential of hydraulic fracturing and advanced modeling tools in unlocking gas reserves in Pakistan’s laminated reservoirs.