Quantify the intake profile of treatment fluid along the wellbore.

Improving Foam Quality in Elks Hills Field

Published: 01/01/2009

Improving Foam Quality in Elks Hills Field

Published: 01/01/2009

Uncertain pressure

An operator in Elks Hills oil field encountered complications while stimulating a shale well near Bakersfield, California, US. The well needed treatment on long, heterogeneous intervals (>1,000 ft). Other wells in the shale had low BHP, but exact measurements were unavailable; instead, the operator routinely estimated expected BHP, and the result was not always accurate. Experience had proved that BHP derived from measured wellhead pressure was often inaccurate in low-pressure wells, especially when introducing foam into the annulus. Similarly, accurately deriving BHP from measured circulating pressure was also outside the scope of most simulation software. Without real-time BHP, an assumed BHP was the starting point of any calculation, which resulted in calculated guesswork.

No production log was possible for these wells, so a typical completion strategy was to either run a slotted liner or perforate a large portion of the horizontal completion. During well stimulation, a large mud acid treatment was generally completed with either foamed acid or foam diversion stages. Postjob calculations of FQ suggested some jobs were completed with as little as 30% FQ, when program requirements specified 70%.

For CT matrix stimulation using foam for diversion, the operator needed highly accurate data.

Real-time measurements

Schlumberger proposed the use of ACTive in-well live performance services to solve this problem. The ACTive family uses real-time downhole measurements to interpret and optimize treatments while they are still in progress. These real-time CT services allow monitoring and evaluating job progress, optimizing treatment results, and interveningwith one trip in hole. The system consists of a BHA, surface electronics, and dynamic interpretation software. It delivers internal and external pressure, temperature, casing collar locator (CCL) depth correlation, and a distributed temperature survey (DTS).

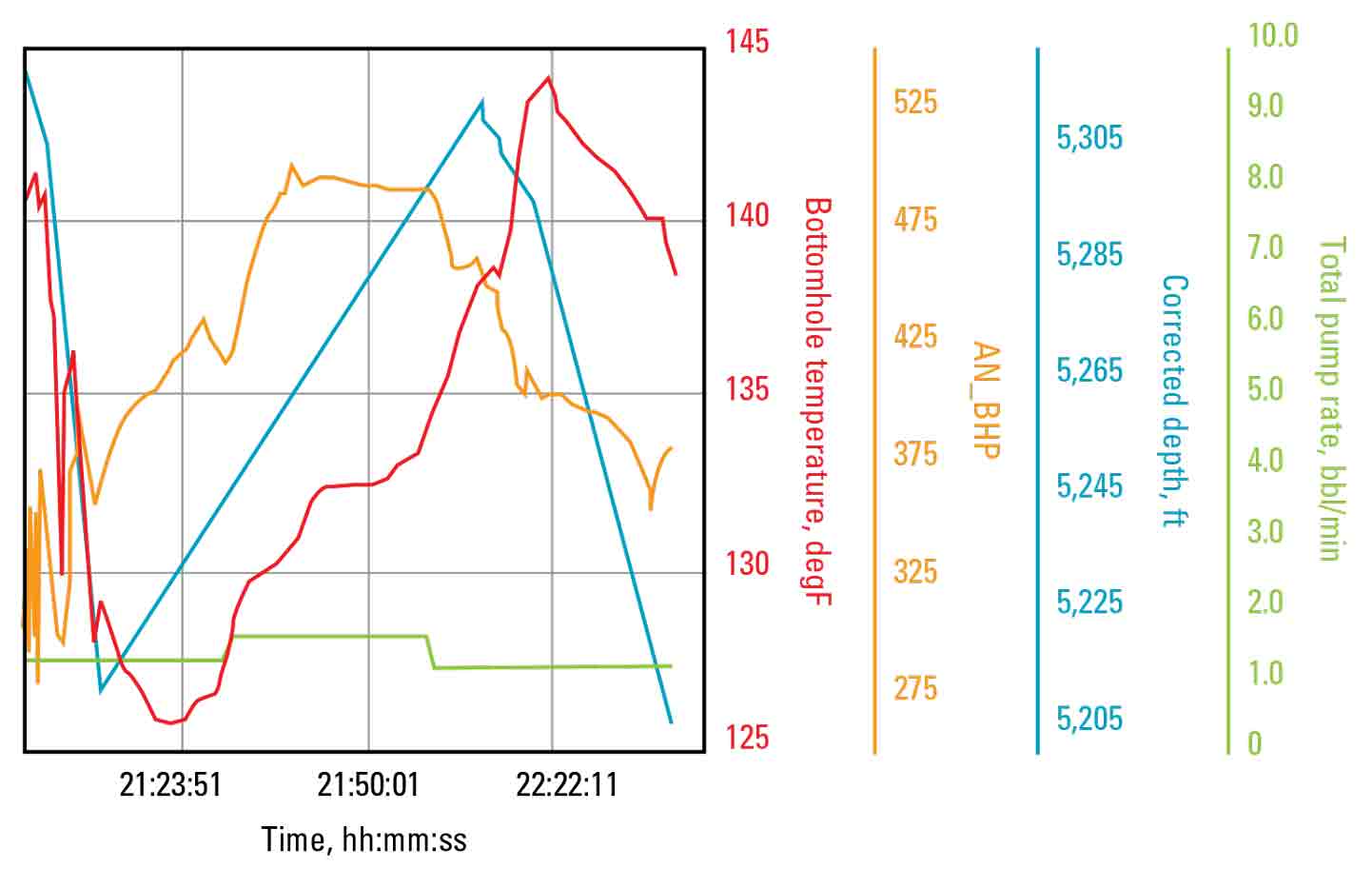

In the Elks Hills well, the ACTive service replaced assumed pressures with real-time data, which allowed adjusting rates to meet the specified FQ percentage. ACTive data also confirmed that BHP was only 300 psi instead of the anticipated 1,200 psi. This dramatic difference meant reducing nitrogen gas rates to supply the required 70% FQ during the diversion stage. If rates had been pumped as per design, an FQ of approximately 90% would have been pumped. As a result of the lower-than-expected BHP, a planned nitrogen lift was applied in time.

Less time and cost

The use of the ACTive solution saved the operator more than USD 10,000 and 5 hours of time compared with the traditional methods used in the field. In addition, the updated pressure data provided helpful insight for offset well candidate selection.

Challenge: Collect enough downhole information to execute foam diversion according to design during the coiled tubing(CT) matrix stimulation of an underperforming oil and gas well

Solution: Implement ACTive real-time downhole CT services to determine bottomhole pressure(BHP) data, which had been calculated years earlier and was often incorrect

Results: Used real-time data to adjust foam quality (FQ) as needed, resulting in excellent diversion and good stimulation. Saved more than USD 10,000 and 5 hours over traditional methods