Extend run life and increase ROP in hard, abrasive formations.

Drilling System Saves 18.5 Rig Days in Eastern Siberia

Published: 11/25/2013

Drilling System Saves 18.5 Rig Days in Eastern Siberia

Published: 11/25/2013

Increase ROP and drill farther in Siberian field

An operator drilling in eastern Siberia wanted to increase ROP and drill more meters per run in a field characterized by

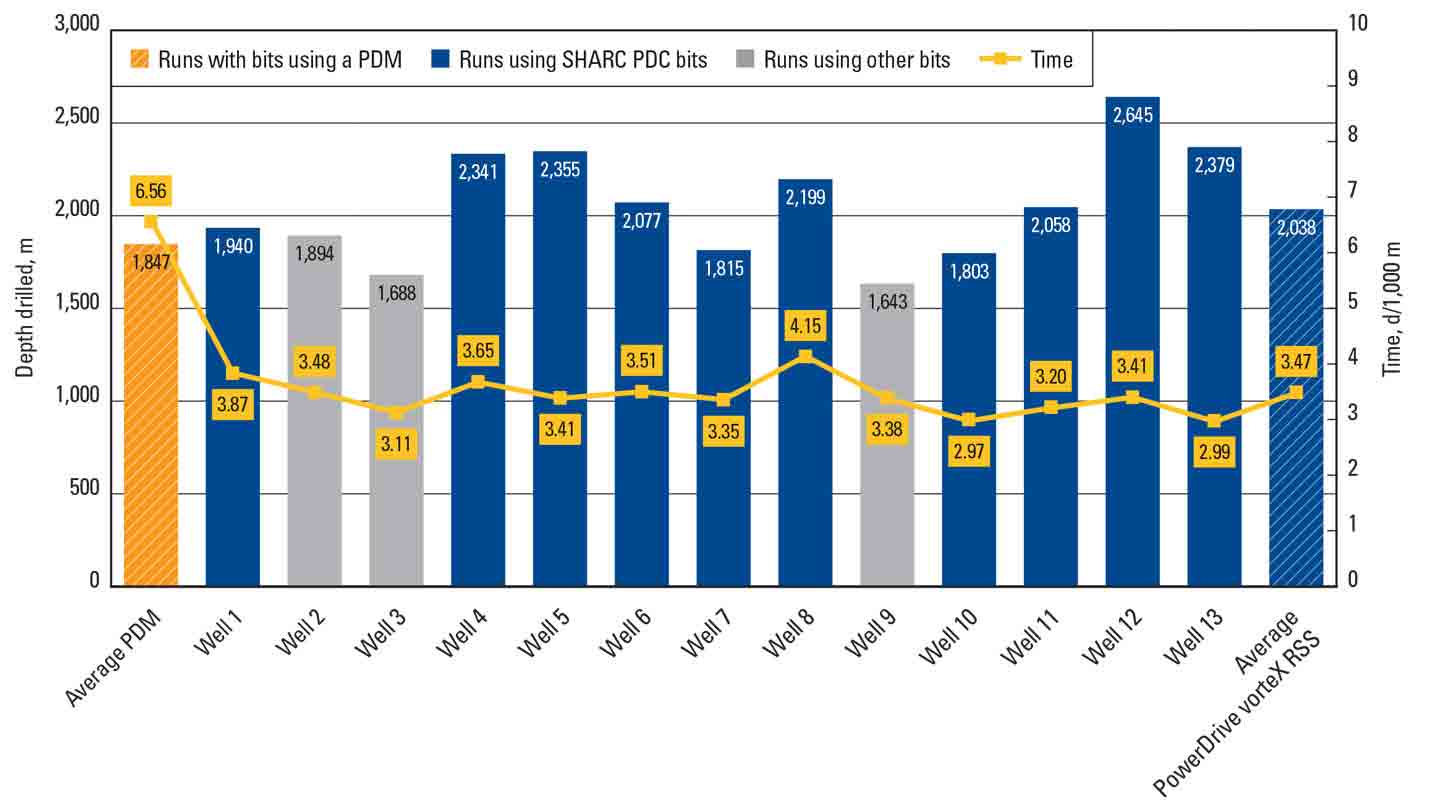

The operator's previous drilling efforts in the field using bits on a positive displacement motor had resulted in low ROP, disappointing run lengths, and poor borehole quality that often prevented running casing efficiently.

Optimize BHA for greater durability

Schlumberger used the IDEAS integrated drillbit design platform to

optimize an

8 1/2-in SHARC MDSi716 PDC bit, which was fitted with ONYX II

premium cutters for superior resistance to abrasive wear and thermal

degradation. The bit design included a row of backup cutters positioned to

provide maximum durability in the nose and shoulder areas of the bit's cutting

structure without compromising ROP.

The SHARC bit from Smith Bits, a Schlumberger company, was run on PowerDrive X6 and PowerDrive vorteX RSSs for accurate wellbore placement, borehole quality, and additional torque. ASPHASOL shale inhibitor from M-I SWACO, a Schlumberger company, was used to stabilize shale sections and control solids dispersion.

Increase ROP, save rig time

The average ROP in the field increased from 6.53 to 21.41 m/h, and meters drilled per circulating hour increased from 4.77 to 12.61.

Directionally drilling 2,644 m in Well 1 marked the longest single run in the field, surpassing the previous record by approximately 300 m and saving 10 rig days.

The extended-reach directional drilling operation in Well 2 resulted in drilling a 3,824-m lateral in a single run, which was a 50% increase in meters drilled that allowed the operator to reach TD 6 days ahead of AFE.

On Well 3, the integrated drilling system achieved an average ROP of 34.1 m/h and 20.5 m drilled per circulating hour. These increases set field records and enabled the operator to reach TD 2.5 days ahead of plan.

Challenge: Increase directional drilling performance for 8 1/2-in well sections in eastern Siberia.

Solution:

- Design a BHA that includes an 8 1/2-in SHARC high-abrasion-resistance PDC drill bit fitted with ONYX II premium PDC cutters run on PowerDrive X6 rotary steerable system (RSS), PowerDrive vorteX powered RSS, and PowerPak steerable motors

- Use ASPHASOL shale inhibitor to stabilize shale sections

Results:

- Drilled multiple 8 1/2-in sections, increasing average ROP, meters drilled, and meters drilled per circulating hour

- Saved 18.5 rig days on three wells