Eliminate shale instability with a stable, reusable solution for openhole gravel-pack completion challenges.

Operator Achieves 100% Gravel-Pack Completion Efficiency and Improves Productivity Index by 30%

Published: 01/19/2016

Operator Achieves 100% Gravel-Pack Completion Efficiency and Improves Productivity Index by 30%

Published: 01/19/2016

Improve fluid displacement and gravel-pack efficiency

In an offshore Norway field, an operator had been drilling wells with an oil-base reservoir drill-in fluid (RDF) and completing the wells with an openhole gravel pack using a brine-base carrier fluid. On a number of wells in the field, the operator experienced inefficient fluid displacement and incomplete gravel packing, resulting in production that fell short of the forecasted PI. This necessitated an oil-base gravel-pack fluid that is compatible with oil-base RDF and would aid in achieving a complete pack by avoiding shale collapse, emulsion issues between the oil-base RDF and brine, and losses caused by filtercake instability.

For its future gravel-pack completions, the operator hoped to achieve a complete gravel pack and improve the PI while reducing the costs and environmental impact associated with the high volume of interfaced brine and oil mud interface from preceding gravel packs.

Replace brine with low-viscosity PrimoPAC fluid for greater stability

In subsequent wells in the field, the operator decided to replace brine with the PrimoPAC fluid. The solids-free fluid was designed to mitigate fluid displacement and gravel-pack challenges with minimal components for straightforward surface and downhole management. PrimoPAC fluid delivers Newtonian fluid rheologies that maintain low viscosity up to 300 degF [149 degC] bottomhole static temperature (BHST). The fluid's simplified displacement eliminates fluid-fluid compatibility and shale stability issues during gravel packing.

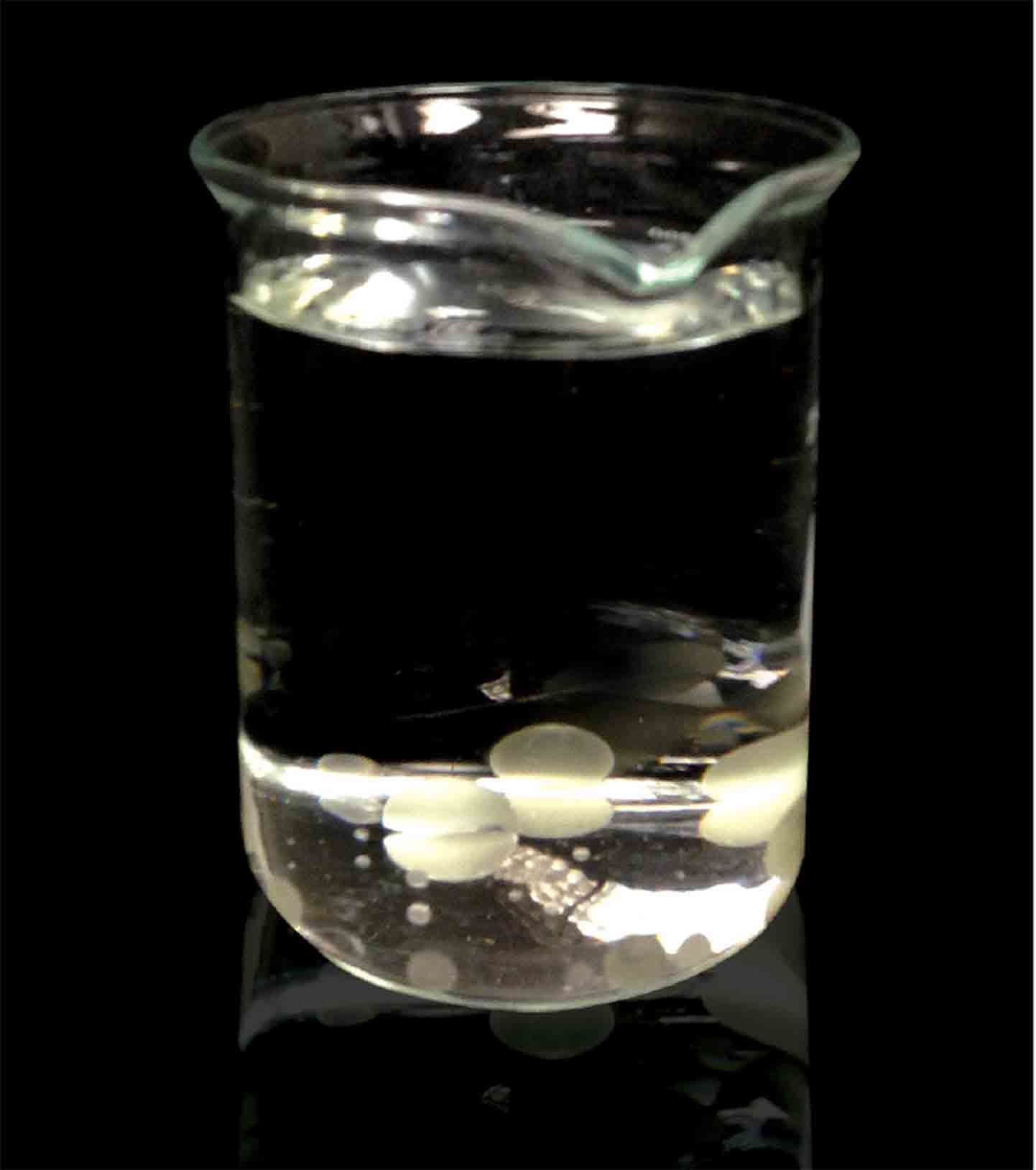

With only three required components—base oil, brine droplets, and the PRIMO-SURF low-oil/water ratio invert-emulsion system primary emulsifier—the fluid was batch mixed onshore at the mud plant and shipped for the job offshore. The process simplified logistics and reduced mixing time.

In this application, the PrimoPAC fluid delivered Newtonian viscosities of 11 cP [0.01 Pa.s] and 20 cP [0.02 Pa.s] at bottomhole circulating and ambient temperature, respectively. The bottomhole circulating temperature was 122 degF [50 degC].

Exceeded PI goals by more than 30% with customized formula

To achieve its gravel-pack completion objectives, the operator tailored the formulation of PrimoPAC fluid based on individual well conditions. The fluid was batch-mixed at the mud plant in Bergen, Norway, and shipped to the rig offshore. The PrimoPAC fluid maintained its properties during the job and in storage for more than 16 months between jobs. With the aid of a stringent QA/QC protocol, more than 75% of the fluid was reused on subsequent jobs.

The use of PrimoPAC fluid enabled the operator to properly complete wells in a way that had not been possible with the use of a water-base fluid (i.e., brine) alone. Since PrimoPAC fluid was deployed in the field, four wells have been successfully gravel packed with 100% pack efficiency. The effective displacement ability of PrimoPAC fluid helped reduce waste, saved rig time, and enabled the operator to exceed PI expectations by more than 30%.

![For well-control purposes, the operator deployed PrimoPAC fluid at a density of 9.16 lbm/galUS [0.91 g/cm3]. An internal-phase brine of calcium chloride and calcium bromide was used at an oil/brine ratio of 60:40.](/-/media/files/mi/case-study/primopac-north-sea-cs-b.jpg)

Challenge: Increase gravel-pack completions efficiency in an offshore reservoir in which a brine-base carrier fluid had been previously used.

Solution: Replace brine with PrimoPAC invert-emulsion gravel-pack carrier fluid for enhanced inhibition and improved gravel placement achieved through ideal viscosity.

Results: Surpassed productivity index (PI) forecast by 30% with 100% gravel-pack completion efficiency across four wells; reused large percentage of PrimoPAC fluid on subsequent jobs in the field.