Deploying an Emissions Management Digital Strategy for a Dynamic Energy Environment

Published: 06/21/2022

Deploying an Emissions Management Digital Strategy for a Dynamic Energy Environment

Published: 06/21/2022

As the oil and gas industry counts down to net zero, transparency and provable emissions reduction progress will be increasingly important. What this translates to for the industry is a compelling business need to effectively leverage its emissions data for both optimizing its abatement and production strategies and for environmental, governance, and sustainability (ESG) reporting purposes.

Related: Methane and Flare Emissions—A Fixable Problem

We sat down with Schlumberger’s Emissions Business Digital Manager Staffan Tekin Eriksson to talk about what it takes to successfully bring copious amounts of emissions data into the fold of field and business operations and the inevitable integration complexity that comes with that.

The company recently launched Schlumberger End-to-end Emissions Solutions (SEES), a new business to address methane and flare emissions. Tell me more about your role with SEES and what kind of conversations you’ve been having with customers.

So, the most important aspect of my role with SEES is advising asset, IT and environmental teams on their emissions management digital strategy and capabilities. When I meet with a customer, the first thing they usually want to know is what needs to be measured and how. The next thing is what is it going to take for these multiple data streams to be trusted by end users. And then finally, how’s the data going to integrate with existing production and field management systems to reach the right people in the right place and at the right time. These are th e nuts-and-bolts discussions that I have with these teams, but the conversation gets interesting when we talk about what we can do to help their business use emissions data for more than just compliance.

Tell me about some of these opportunities. What can SEES help customers do beyond compliance?

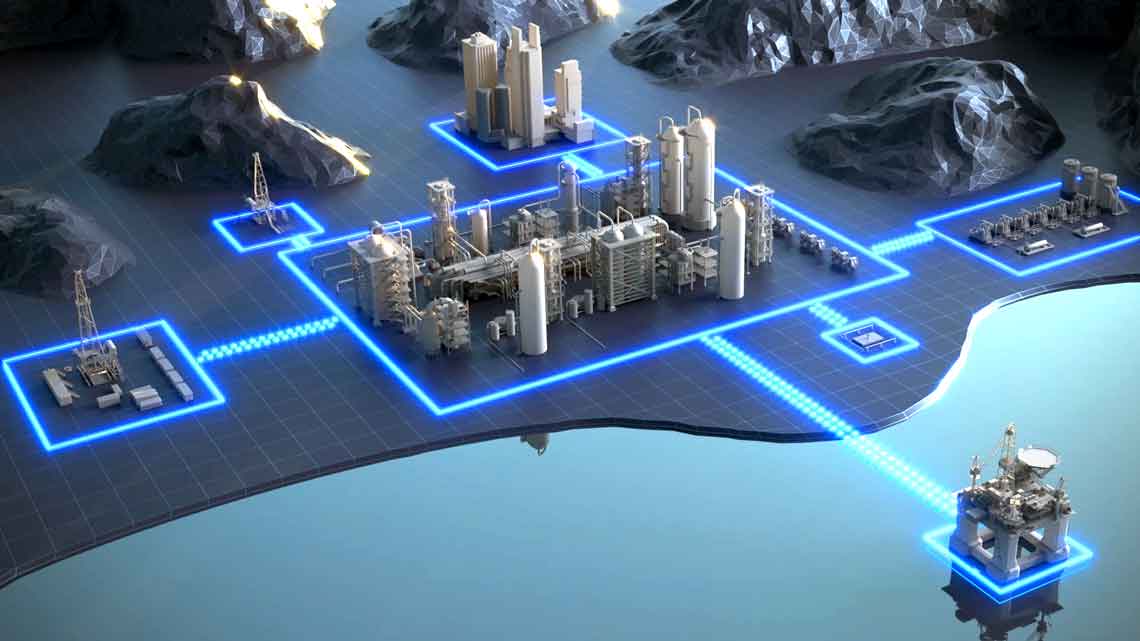

The short is answer is a lot. One example is capturing more sales gas with the money already spent on compliance and designing the optimal tradeoff between methods of inspection or looking ahead to what the next regulatory or tax change may mean for their operations. By better understanding what’s emitting, we can focus resources where our customers will make the biggest impact, which in many cases results in cost savings. We do this by following a holistic approach built on three pillars—plan, measure, and act. All three pillars are underpinned by the industry's first methane emissions digital platform, which is accessible in the DELFI cognitive E&P environment, to provide a comprehensive and differentiated path for operators to achieve their decarbonization objectives. Our vision is to embed the expertise of our SMEs from around the world within our digital platform and provide access to the multi-domain intelligence that will be needed to adapt to the dynamic regulatory and operating environment the industry faces. It’s better to stay in control and ahead of the curve.

Plan

Whether you're looking to comply with Oil & Gas Methane Partnership (OGMP) 2.0 reporting standards, satisfy regulatory requirements, earn certification, achieve zero routine flaring, or simply reduce emissions as economically as possible, we begin by understanding your asset and emissions management goals. Our oilfield experts have a deep knowledge of emerging standards and technologies and have customized plans to help customers progress through all OGMP levels. We'll work closely with you to develop your methane and flaring strategy.

Measure

We offer a full range of measurement technologies and use various approaches: bottom-up for OGMP Level 4, top-down for OGMP Level 5, and continuous monitoring. All Emissions Technologies and Solutions technologies provide quantitative emission rate measurements that are backed by extensive controlled release testing performed in partnership with multiple universities. Because no single technology is perfect, combining our measurements offers the benefit of trusted data from a single source. Our end-to-end approach involves selecting technologies, performing the measurements, and reconciling the data.

Act

We perform measurements that provide actionable information and turn insights into action by fixing emissions. Our team repairs leaks, performs facility audits to identify the root causes of emissions, and installs equipment to reduce or eliminate emissions. We do this keeping in mind the optimal methods that can eliminate methane emissions faster and with less cost. No matter the challenge, we’re committed to implementing practical measures that have the biggest positive impacts on your business, and the planet.

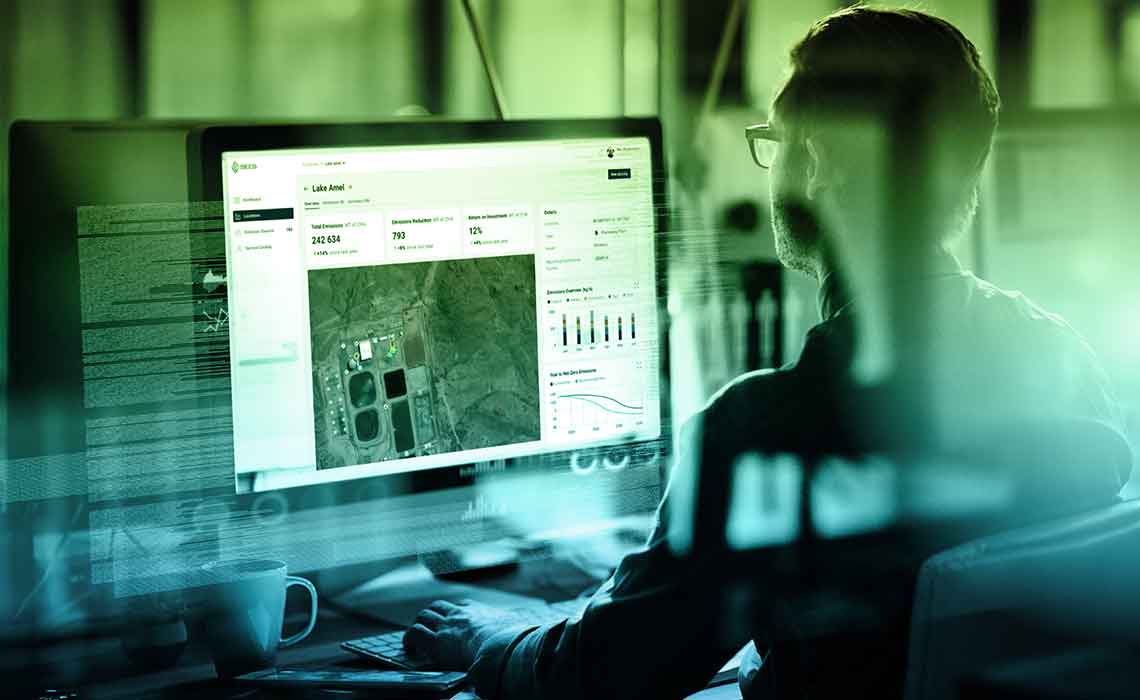

Digital integration

We recognize that managing emissions data can be manually tedious when information is spread across multiple sources, resulting in costly time spent. Our methane digital platform is an emissions management software tool designed to integrate the data from all your measurement systems in a single location. We built this tool to ensure that your methane plans, measurements, and actions are easily accessible and facilitate efficient data management and reporting. With a full, accurate view of emissions across your organization, you’re empowered to make informed decisions and drive meaningful progress.

How do you view the role of digital in helping operators balance their production targets with emissions reduction?

Today, emissions data cannot exist in a silo and at the same time have any significant impact on the business outside of compliance. This data needs to land with other data, including from production, in real time to enable key decision makers within the business to make better, more informed decisions on compliance and production operations.

But bringing all this data together, and making it relevant to the user, is a major challenge.

To get past this hurdle, we provide SEES customers with a digital platform that enables them to integrate emissions data with data from their other processes. This enables us to provide tailored service offerings that are designed to help them optimize their emissions reduction initiatives. We help our customers cut through the noise of different vendor data formats and interpretation and focus on action that can make real impact for reduction. Using this platform, our customers can start to do things like correlate equipment with leaks, design optimal inspection programs or triage which opportunities to tackle first, based on historical data from their assets. This results in a new set of opportunities for stakeholders when they begin to recognize that their emissions data can be used to inform these decisions without manual and expensive data wrangling.

Let's dive more into the integration. What does it entail?

What you often see is in-house teams piloting emissions monitoring technologies, stringing together dashboards to meet the initial needs of this business. This may work fine for a time, but it’s not sustainable in the long term as the needs of the business change.

With the growing importance of methane and flare emission reduction for business, combined with the push for continuous operational performance improvement, it doesn’t pay for IT and asset teams to be shortsighted.

In the very near future, end users will need to do more with emissions data, including creating AI models for more predictive monitoring. The system will need to scale to meet these needs. On top of this, maintenance of this system will be required to address dynamic vendor and regulatory requirements. The data will also need to be easily accessed, verifiable and auditable for it to be trusted. That’s hard to do, if not impossible, without a seamless, consistent and secure digital environment—and that takes continuous investment and maintenance.

SEES wants to simplify the management of different vendors and formats and make it easy and flexible to integrate emissions and operations data, analyze the data, and inform high-value tasks that improve performance and reduce emissions.

What are the most important takeaways from our conversation today?

When it comes to integration, it’s important for IT and asset teams, and their end users, to know that simply landing data in one place doesn’t mean that it can be trusted for decision making. This data needs to be given the proper context to be useful. It also needs live in a seamless, consistent environment that isn’t going to break as the needs of the business grow and that supports rapid experimentation and learning.

Finally, emissions data needs to satisfy business-critical compliance and reporting needs, but it must go beyond this. To fully optimize oil and gas operations today and throughout the energy transition, this data needs to enable proactive rather than reactive emissions abatement strategies and enhance overall production performance at a lower emission intensity per barrel. Data platforms and digital ecosystems that bring data from across operations into context for end users and enable on-the-ground action are vital to making this possible.