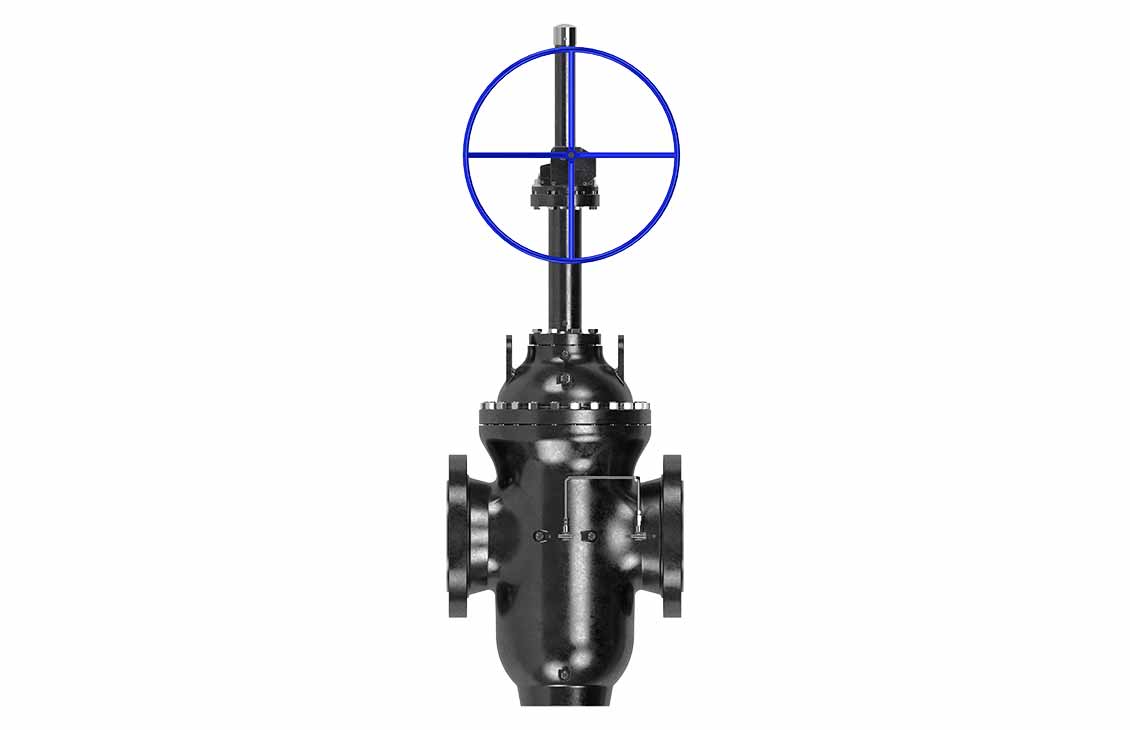

Valves for ammonia service

Proven valve solutions for ammonia production and transportation, including ammonia pipelines

Why choose SLB valves for ammonia applications?

Ammonia is critical for agriculture worldwide. It can also support the energy transition as a hydrogen carrier and industrial fuel source for the future. As interest in ammonia production and transportation projects increases, equipment manufacturers must be ready to supply products that can overcome the associated challenges. With decades of experience in providing valves for ammonia applications, SLB has the product qualifications and trim options to ensure long-term, reliable service.

Low emissions certified portfolio

Because it is a highly toxic and potentially combustible fluid, ammonia must be

contained within piping systems. Our extensive range of fugitive emissions certified valves helps ensure long-term containment of ammonia, even under the most demanding

conditions, minimizing your environmental impact and HSE risk.

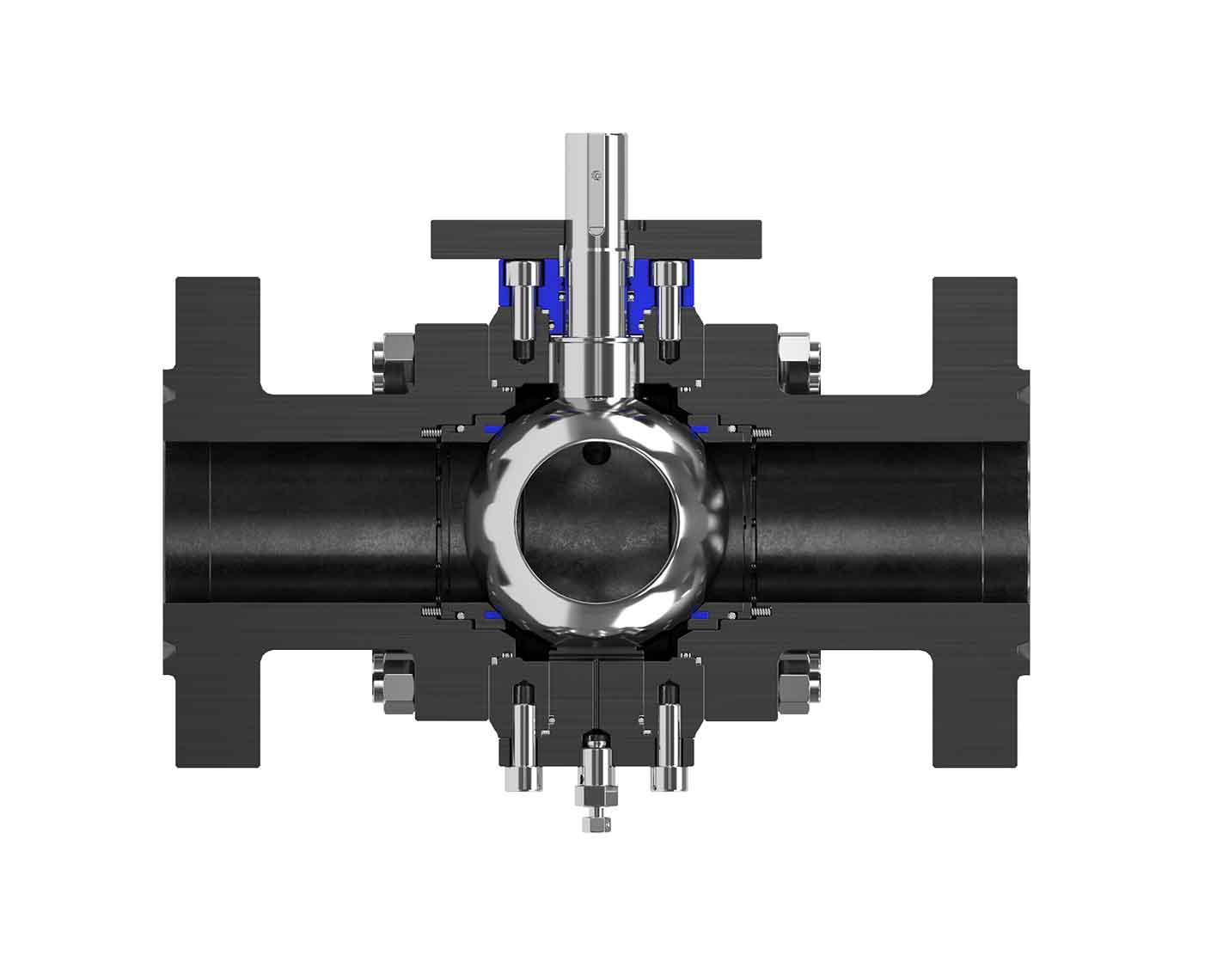

Trim selection

Depending on the presence of contaminants such as

water or air, ammonia can create a significant risk of

corrosion and stress cracking in metallic materials. It

also adversely affects nonmetallic materials and

attacks many of the elastomers commonly used in oil

and gas operations. We leverage our extensive

expertise and resources to employ materials that

deliver long-term performance.

Comprehensive offering

Along the ammonia value chain, you will find both

liquid and gas phases as well as a range of operating

pressures and temperatures. Regardless of the

conditions, we have products to suit. In addition, we provide a host of auxiliary services, including digital enablement, monitoring, valve evaluation for repurposing pipelines, and a suite of total valve care solutions.