Cameron T30 Series

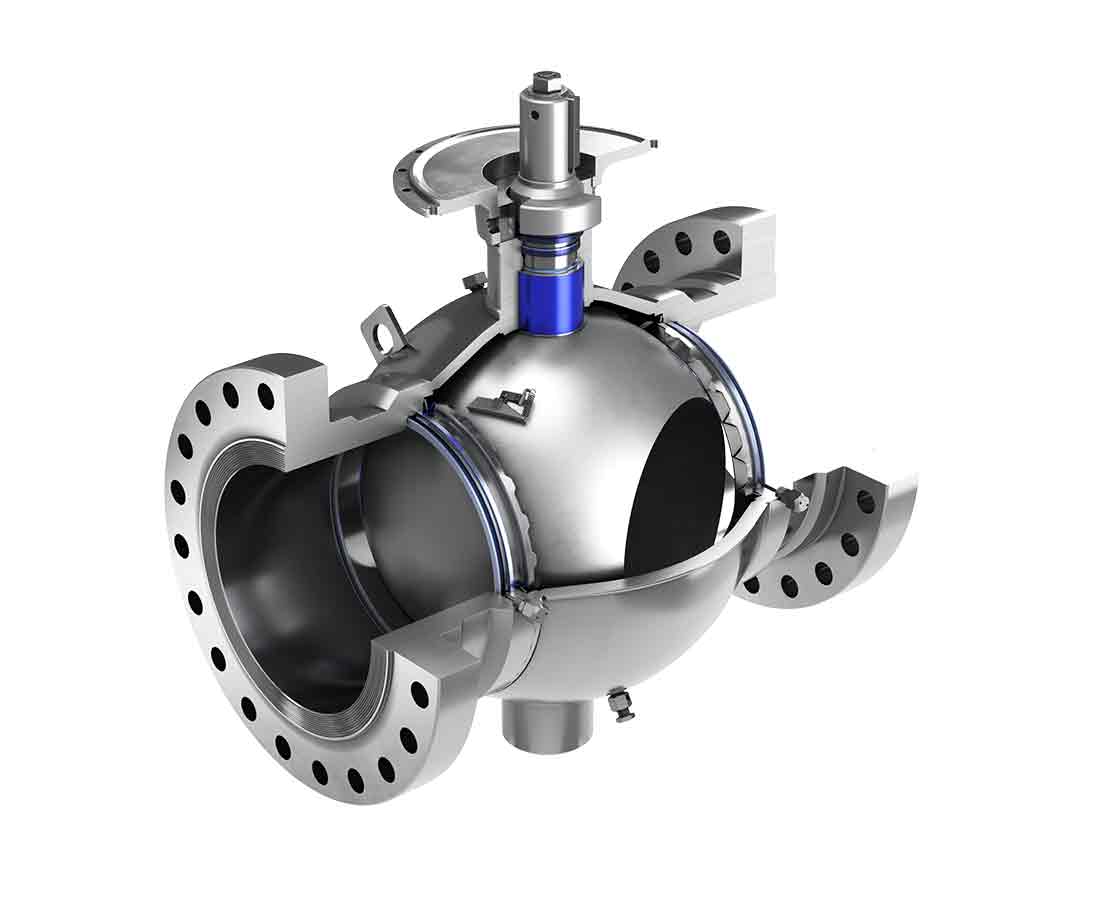

Fully welded ball valve

Emissions reduction

Lower emissions while improving profitability

Cameron T30 Series™ fully welded ball valves reduce the total cost of ownership by minimizing fugitive emissions, simplifying maintenance, and eliminating valve replacement or upgrading at a later date to satisfy environmental regulations.

They combine the strength of forged components with a compact lightweight spherical design that eliminates body flanges to reduce overall size and potential leak paths. In addition, the superior stem sealing system is elastomer free. The valves provide a longer service life and optimal resistance to pipeline pressures and stresses.

- Isolation valve for aboveground and buried pipeline installations

- Long-term gas storage facilities

- Compressor, gathering, and metering stations

- Gas terminals

- Residential gas installations

- Onshore and offshore production and gas and LNG processing

- Subsea isolation

- Measurement skids

- Oil and gas dehydration systems

- Hydrogen, CCUS, renewable fuels, and ammonia service

Decrease long-term costs

Increase revenue

Enhance safety

Reduce handling risk with lower weight.

Lower emissions

- All-welded construction for greater strength

- Sealing options: self-relieving (T31 valve), double piston effect or DIB*-1 (T32 valve), or a combination of both or DIB-2

- Double block-and-bleed as standard in both closed and open positions

- Antiblowout stem design

- Thermoplastic seals with no aging effect and no susceptibility to explosive decompression

- Belleville springs that maintain constant spring force and protect seat-to-body seal

- Robust stem stops that withstand actuator torque

- Stem stop viewports that enable verification of proper valve position

- Seat and stem injection ports with internal check valve

- Rotating seats that spread wear over the entire sealing surface for longer service life

* Double isolation and bleed

Reduce your carbon footprint

CAMERON T30 Series ball valves are part of our Transition Technologies™ portfolio. By mitigating and preventing fugitive CO2e emissions, these API- and ISO-certified valves present a low-risk, high-yield opportunity to reduce environmental impact. They help you reach your sustainability goals and maintain your social license to operate.

Learn moreThe content of this publication has not been approved by the United Nations and does not reflect the views of the United Nations or its officials or Member States.