Corrosion Inhibitors

For crude oil pipeline and oil and gas production asset integrity

Preserve asset integrity with a comprehensive portfolio of chemical treatments.

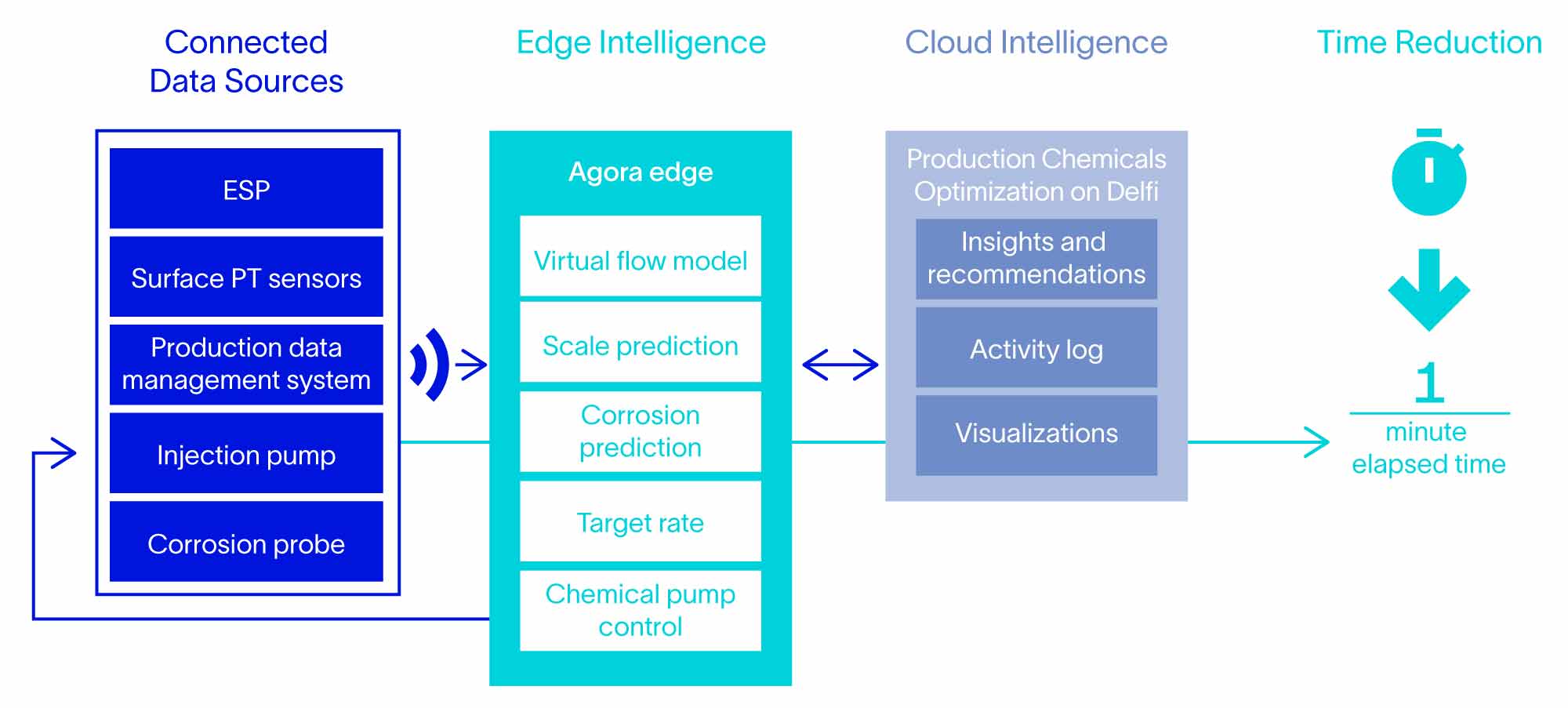

Production systems are dynamic by nature, with constantly varying conditions. That’s why chemical injection systems must be repeatedly adjusted to ensure continuous protection of critical assets and optimize opex. Production Chemicals Optimization on Delfi™ innovatively solves the common flow assurance and asset integrity challenges of corrosion and scale by harmoniously adjusting chemical injection to the changes in production.

By leveraging digital capabilities, what were previously manual chemical treatment processes requiring frequent field visits are transformed into autonomous chemical injection systems. Your existing equipment is connected for real-time data acquisition to inform inline use of physics-based models such as a virtual flowmeter, edge analytics, and cloud computing. From this contextual basis, Production Chemicals Optimization on Delfi autonomously generates actionable insights and adjusts chemical injection. This continuous optimization of injection extends both ESP uptime and the life of production equipment. The number of field visits is significantly reduced, along with their carbon emissions.

Production Chemicals Optimization on Delfi is one of our suite of digital production chemicals products, tiered to meet any operational requirements and expectations.

The challenge: Manual performance monitoring delays event detection. Corrosion and scale are two of the most common challenges facing producers today, with inhibitors accounting for >50% of the USD 8 billion global production chemical spend. The problem in managing corrosion and scale through chemical injection does not lie in inhibitor formulation—these are proved to be highly effective in protecting production systems. The weak link in chemical treatment programs is the manual technique traditionally employed to monitor risks and chemical performance, which introduces delays in taking preventive action and undermines alignment of the chemical treatment with the ever-changing well conditions.

The solution: Production Chemicals Optimization on Delfi significantly reduces the time from insight to action by acquiring and processing data in real time to provide continuous optimization recommendations and autonomous action.

The challenge: Ineffectively managed corrosion and scale risk can lead to wells failing prematurely. This causes producers to incur increased workover costs and experience decreased production revenue. For example, an onshore producer had a conventional manual corrosion and scale chemical treatment program but was running up more than USD 8 million in annual workover costs and more than USD 5 million in annual production losses. These costs were largely due to the suboptimal frequency inherent in manual corrosion and scale risk monitoring methods.

The solution: Production Chemicals Optimization on Delfi leverages edge intelligence via Agora™ edge AI and IoT solutions and executes physics-based models using real-time data to continuously monitor changes in well conditions and their impact on corrosion and scale risk for ultimately mitigating the occurrence of well failures.

The challenge: Wells are not static systems, yet manually managed chemical treatments can remain unchanged for weeks until new data is made available. This lack of treatment alignment results in chronic overtreatment or undertreatment, neither of which mitigates corrosion and scale risk effectively and can lead to production shutdowns and increased costs.

The solution: Production Chemicals Optimization on Delfi enables real-time optimization, including autonomous control of the chemical injection pumps. The result is chemical injection that is continuously on target, eliminating over- and undertreatment and their deleterious effects on production.

The challenge: Ineffective production chemical treatment affects ESP performance. It is the root cause of >20% of ESP failures, resulting in lost production and rising workover costs. Over- and undertreatment issues primarily stem from the inability of traditional manual monitoring of changes in well conditions to provide data at sufficient frequency for continuously optimizing chemical treatments.

The solution: Production Chemicals Optimization on Delfi enables monitoring critical data such as production rates, injection rates, and scale and corrosion risk in real time so that interventions can be performed at optimal frequency.

By digitalizing monitoring, analysis, prediction, and treatment as a continuous closed-loop process, Production Chemicals Optimization on Delfi makes critical data such as production rates and system risks available as often as every minute, depending on the operator’s data frequency. Furthermore, Production Chemicals Optimization on Delfi is an open system, applicable regardless of the chemical or ESP provider. Operators’ organizations are provided with cloud-based access to real-time data updates as frequently as 1,440 times per day. Autonomous surveillance and injection rate optimization mean that ESPs are protected against corrosion- and scale-induced failures, which enables increased uptime and ultimately production revenue.

Contact Michael Van Spankeren, digital solutions manager production chemistry, to learn what Production Chemicals Optimization on Delfi can do for your wells’ performance.

Contact Our Expert

Reimagine energy performance and improve decision making with connected, intelligent, and autonomous solutions.

Learn more